Nov . 08, 2024 20:29 Back to list

liquid graphite lubricant factories

The Role of Liquid Graphite Lubricant Factories in Modern Industry

In the fast-evolving landscape of manufacturing and engineering, efficient lubrication solutions have become crucial in enhancing machinery performance and reducing maintenance costs. Among these, liquid graphite lubricants have emerged as an innovative solution, characterized by their unique properties and versatility. As the demand for high-performance lubricants grows, liquid graphite lubricant factories are strategically positioned to play a pivotal role in various industries.

Understanding Liquid Graphite Lubricants

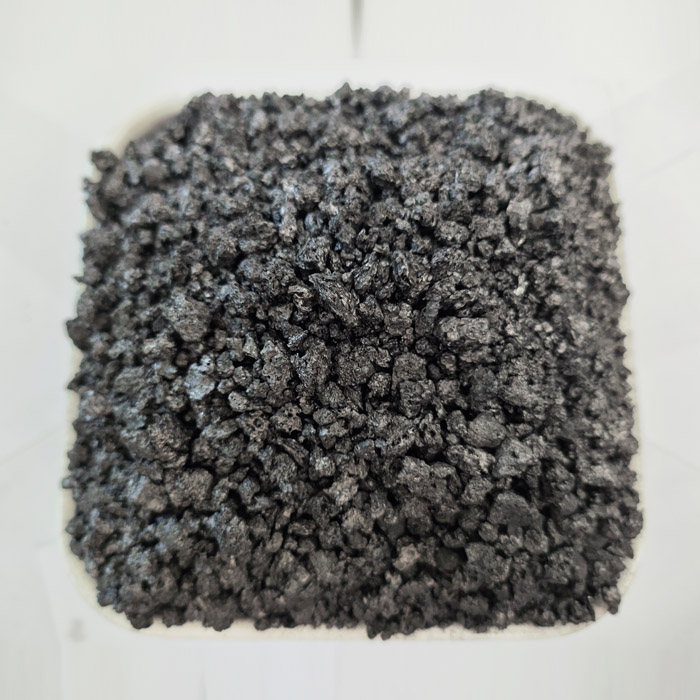

Liquid graphite lubricants are formulated using finely milled graphite particles suspended in a liquid carrier. This combination not only provides excellent lubrication properties but also ensures high thermal stability and resistance to extreme pressures. The unique characteristics of liquid graphite make it suitable for applications in diverse sectors, including automotive, aerospace, and industrial machinery.

One of the main advantages of liquid graphite lubricants is their ability to reduce friction and wear between moving parts. The graphite particles create a lubricating film that minimizes direct contact between surfaces, thereby extending the lifespan of machinery and components. Additionally, liquid graphite is non-toxic and environmentally friendly, making it a preferred choice for industries that prioritize sustainability.

The Manufacturing Process

The operation of liquid graphite lubricant factories involves several stages, from the sourcing of raw materials to the final packaging of products. The first step in the manufacturing process is the procurement of high-quality graphite, which is essential for producing effective lubricants. Factories often establish partnerships with reliable suppliers to ensure the consistency and quality of their graphite input.

Once the graphite is sourced, it undergoes a milling process to achieve the desired particle size. The finer the graphite particles, the more effective they are at creating a lubricating film. After milling, the graphite is mixed with a suitable liquid carrier, which serves to suspend the particles and enhance their lubricating properties. This process may involve the use of additives to improve performance characteristics such as adhesion and thermal stability.

liquid graphite lubricant factories

Quality control is critical throughout the manufacturing process. Factories implement rigorous testing procedures to ensure that each batch of liquid graphite lubricant meets industry standards. This includes assessing its viscosity, thermal stability, and lubricating properties. Only once the lubricant passes these tests can it be packaged and distributed to customers.

Applications Across Industries

Liquid graphite lubricants find applications across a multitude of sectors. In the automotive industry, they are used in engines, transmissions, and brake systems to enhance performance and prolong the lifespan of components. In aerospace, the high-temperature stability of liquid graphite lubricants makes them ideal for use in jet engines and other critical components.

Furthermore, in industrial settings, these lubricants are employed in machinery such as conveyors, bearings, and gears, where reducing friction is essential for operational efficiency. The versatility of liquid graphite lubricants allows them to be tailored to meet the specific requirements of various applications, reducing overall operational costs.

Environmental Considerations

As industries move towards more sustainable practices, liquid graphite lubricants present an environmentally friendly alternative to traditional petroleum-based lubricants. Their non-toxic nature and biodegradability make them a compelling option for companies looking to reduce their environmental footprint. Additionally, the extended lifespan of machinery due to effective lubrication translates into less waste and lower resource consumption.

Conclusion

Liquid graphite lubricant factories are at the forefront of industrial innovation, offering solutions that meet the demands of modern manufacturing. By delivering high-performance, environmentally friendly lubricants, these factories contribute significantly to enhancing machinery efficiency and sustainability. As industries continue to evolve, the importance of liquid graphite lubricants in maintaining operational excellence cannot be understated.

-

Eco-Friendly Granule Covering Agent | Dust & Caking Control

NewsAug.06,2025

-

Fe-C Composite Pellets for BOF: High-Efficiency & Cost-Saving

NewsAug.05,2025

-

Premium Tundish Covering Agents Exporters | High Purity

NewsAug.04,2025

-

Fe-C Composite Pellets for BOF | Efficient & Economical

NewsAug.03,2025

-

Top Tundish Covering Agent Exporters | Premium Quality Solutions

NewsAug.02,2025

-

First Bauxite Exporters | AI-Optimized Supply

NewsAug.01,2025