Nov . 19, 2024 08:32 Back to list

low nitrogen recarburiser exporter

Low Nitrogen Recarburiser Exporter A Key Player in Global Steel Manufacturing

As the modern steel industry continues to evolve, the demand for high-quality raw materials is more pressing than ever. One such material that has garnered significant attention is low nitrogen recarburiser. This specialized form of carbon additive plays a crucial role in the production of high-grade steel, offering unique advantages that cater to the varying needs of steel manufacturers worldwide. In this article, we will explore the importance of low nitrogen recarburiser exporters and their impact on the global steel market.

Understanding Low Nitrogen Recarburisers

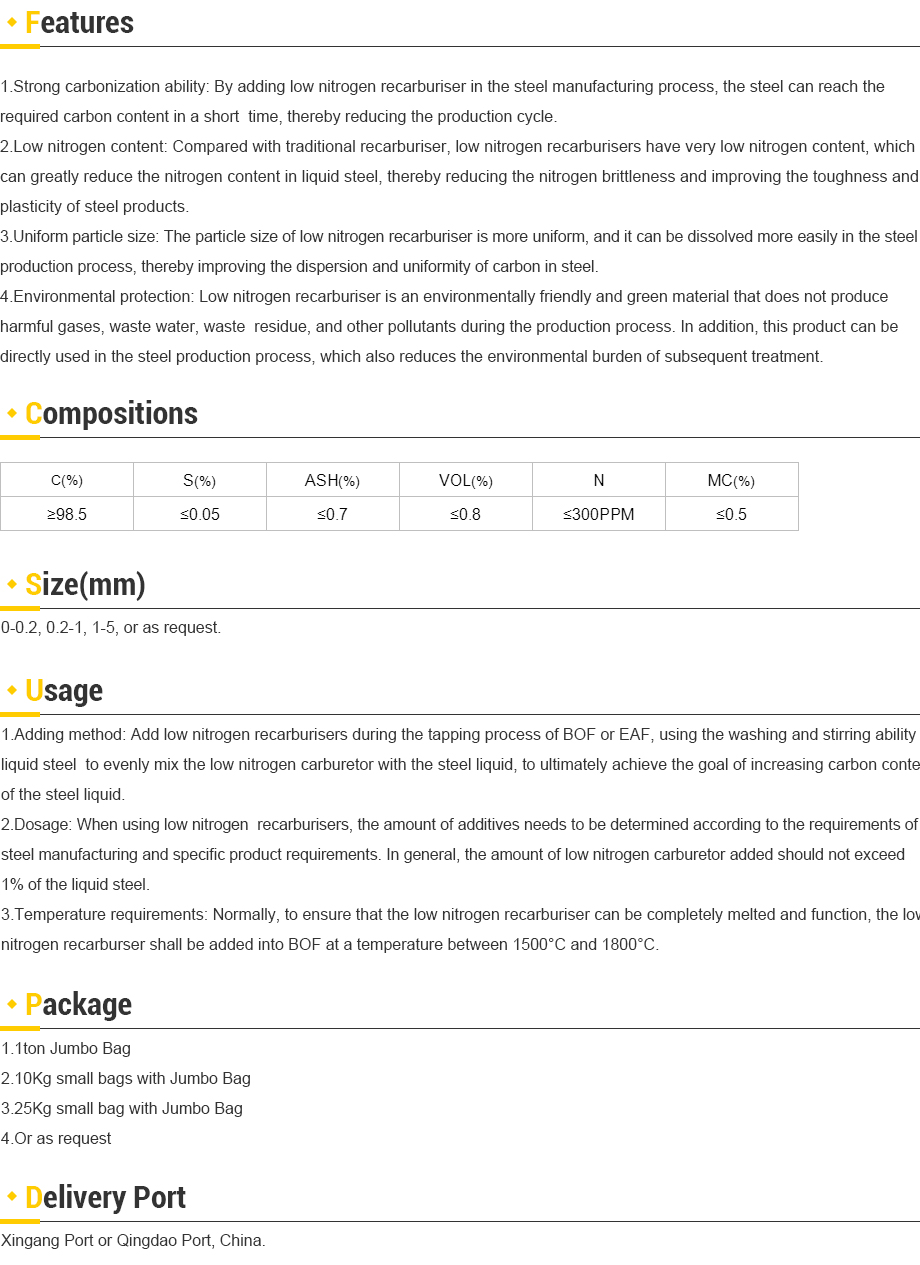

Low nitrogen recarburisers are carbon sources used in the steelmaking process, particularly during the secondary refining stages. Unlike conventional recarburisers, which may contain higher levels of nitrogen, low nitrogen variants contain reduced nitrogen levels. This characteristic makes them particularly valuable for steel grades where nitrogen control is critical. Excess nitrogen can lead to various issues, including increased brittleness, which directly affects the mechanical properties of the final product.

The primary application of low nitrogen recarburisers is in electric arc furnaces (EAFs) and induction furnaces, where precise control over chemical composition is essential. As industries shift towards producing higher-strength and lower-alloy steels, the demand for advanced recarburising solutions continues to rise.

The Role of Exporters in the Supply Chain

Exporters of low nitrogen recarburisers play a pivotal role in ensuring that steel manufacturers can source these specialized materials efficiently and reliably. Their responsibilities encompass various critical functions

1. Quality Assurance Exporters are tasked with maintaining stringent quality checks to ensure that the low nitrogen recarburiser meets the specific criteria of different steel manufacturing standards. This includes adhering to international certifications, which help build trust and credibility in global markets.

low nitrogen recarburiser exporter

2. Market Expansion The global steel industry is characterized by diverse requirements across different regions. Exporters facilitate market expansion by connecting producers in resource-rich countries with manufacturers who require high-quality recarburisers, thereby promoting international trade.

3. Technical Expertise Many exporters offer supplementary services, including technical support and expertise to help steelmakers optimize their processes. This collaboration can lead to improvements in productivity, cost efficiency, and product quality.

4. Sustainability Initiatives In an era where sustainability is paramount, low nitrogen recarburiser exporters are increasingly adopting eco-friendly practices. This includes sourcing materials from sustainable processes and minimizing carbon footprints in transportation and production.

The Growing Demand Amid Global Challenges

The steel industry has faced various challenges in recent years, from fluctuating raw material prices to increasing regulatory pressures regarding environmental impact. As a result, the demand for low nitrogen recarburisers is expected to see substantial growth. Factors such as the rise of infrastructure projects, electric vehicles, and renewable energy developments contribute to this trend.

Moreover, advancements in recycling technologies have led to a shift toward more efficient steel production processes. As manufacturers strive for enhanced quality and lower impurities in their steel products, the utilization of low nitrogen recarburisers will become increasingly significant.

Conclusion

In conclusion, the role of low nitrogen recarburiser exporters is indispensable in the modern steelmaking landscape. By providing high-quality, low nitrogen carbon additives, these exporters not only support manufacturers in achieving superior steel products but also contribute to the sustainability and efficiency of the industry. As global demand continues to rise, the significance of these specialized exporters will undoubtedly grow, shaping the future of steel production worldwide. Without a doubt, they are a key player in driving innovation and quality within this essential industry.

-

Fe-C Composite Pellets for BOF: Enhance Steelmaking Efficiency

NewsAug.07,2025

-

Eco-Friendly Granule Covering Agent | Dust & Caking Control

NewsAug.06,2025

-

Fe-C Composite Pellets for BOF: High-Efficiency & Cost-Saving

NewsAug.05,2025

-

Premium Tundish Covering Agents Exporters | High Purity

NewsAug.04,2025

-

Fe-C Composite Pellets for BOF | Efficient & Economical

NewsAug.03,2025

-

Top Tundish Covering Agent Exporters | Premium Quality Solutions

NewsAug.02,2025