Oct . 16, 2024 06:17 Back to list

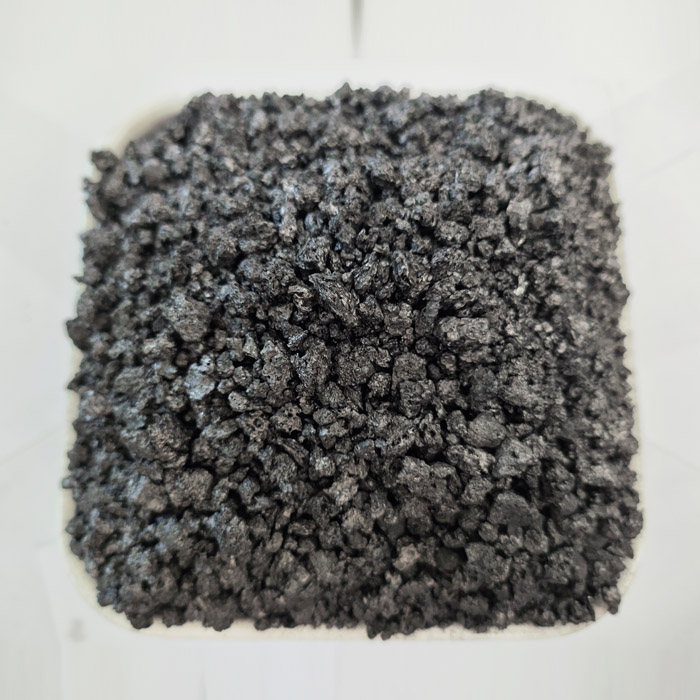

metallurgical slag removal agent exporters

The Role of Metallurgical Slag Removal Agents in the Industry

Metallurgical slag removal agents play a crucial role in the metal production process. These agents are vital for improving the efficiency of steelmaking and other metallurgical operations by effectively handling the slag produced during the smelting process. As global industrial activities grow, so does the demand for efficient metallurgical processes, leading to increased interest and investment in slag removal agents.

Understanding Metallurgical Slag

Slag is a byproduct generated during the extraction of metals from their ores. Composed of various metal oxides, silicates, and other compounds, slag serves both as a waste product and a necessary component for optimal metal production. While it is essential for protecting molten metal from oxidation, excessive slag can lead to inefficiencies and compromises in the quality of the final metal product. The management of this slag is critical to ensuring that the production process runs smoothly and that the quality of metal remains high.

Types of Slag Removal Agents

Metallurgical slag removal agents come in numerous forms, often tailored to the specific requirements of different metals. Common agents include calcium-based compounds, which help in the quick and efficient separation of slag from molten metal. Other agents may include fluxing agents, which are added to alter the chemical properties of the slag, making it easier to manage or recycle. The choice of removal agent can have a significant impact on both the efficiency of the slag treatment process and the overall quality of the metal produced.

metallurgical slag removal agent exporters

Global Export Market

The global market for metallurgical slag removal agents has seen significant growth over the past few years. Exporters are increasingly focusing on providing high-quality and specialized agents to meet the diverse needs of metallurgical companies. Countries with a robust industrial base, such as China, India, and the United States, are leading the way in both production and consumption of these agents. This trend is driven by the continuous advancements in steelmaking technology and the increasing demand for quality steel, driven by construction, automotive, and other industries.

Sustainability Considerations

In recent years, sustainability has become a crucial focus for metallurgical industries. As environmental regulations tighten, slag removal agents that are non-toxic and eco-friendly are gaining popularity. Exporters are developing innovative solutions that minimize environmental impact while ensuring efficient slag management. The use of recycled materials in the production of slag removal agents also aligns with the global movement towards sustainability.

Conclusion

Metallurgical slag removal agents are indispensable in the metal production process, ensuring efficiency and quality. As the industry evolves, so too does the demand for effective and sustainable slag management solutions. For exporters, the challenge lies in balancing quality, efficiency, and environmental responsibility. As the global market grows, investing in innovative and eco-friendly slag removal agents can yield significant returns, benefiting both businesses and the environment alike.

-

Fe-C Composite Pellets for BOF: Enhance Steelmaking Efficiency

NewsAug.07,2025

-

Eco-Friendly Granule Covering Agent | Dust & Caking Control

NewsAug.06,2025

-

Fe-C Composite Pellets for BOF: High-Efficiency & Cost-Saving

NewsAug.05,2025

-

Premium Tundish Covering Agents Exporters | High Purity

NewsAug.04,2025

-

Fe-C Composite Pellets for BOF | Efficient & Economical

NewsAug.03,2025

-

Top Tundish Covering Agent Exporters | Premium Quality Solutions

NewsAug.02,2025