Aug . 29, 2024 21:57 Back to list

metallurgy factories

The Role of Metallurgy Factories in Modern Industry

Metallurgy factories play a critical role in the industrial landscape by transforming raw materials into valuable metal products essential for various applications. These facilities are the backbone of the manufacturing sector, providing metals that are fundamental to construction, automotive, aerospace, electronics, and countless other industries.

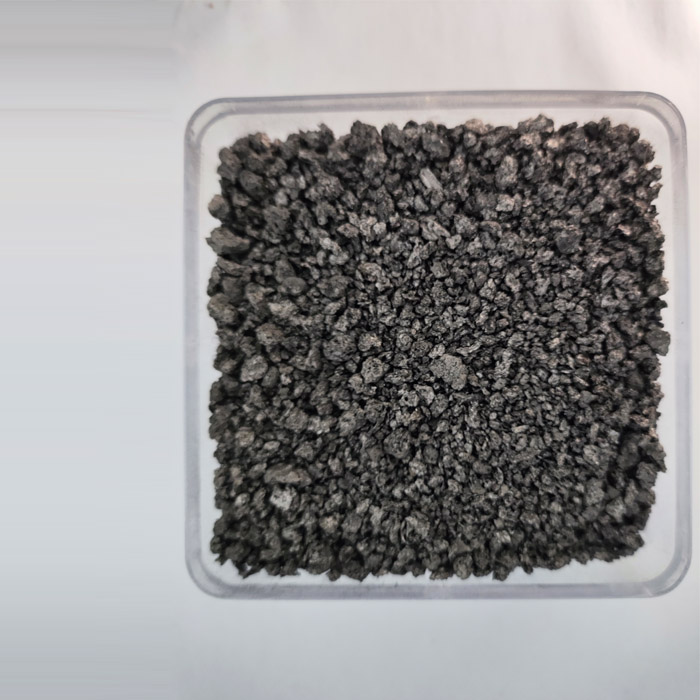

At the core of metallurgy is the extraction and processing of metals from ores. This process begins in large-scale mining operations, where raw minerals are extracted from the earth. These ores contain different metals, such as iron, aluminum, copper, and zinc. Once mined, the ores are transported to metallurgy factories to undergo several processes, including refining, smelting, and alloying, to yield pure metals or metal alloys.

One of the primary processes in metallurgy factories is smelting, where ores are heated to high temperatures to separate the metal from impurities. This process often requires significant energy and advanced technology to ensure efficiency and sustainability. Modern metallurgy factories are increasingly adopting eco-friendly practices, such as recycling scrap metal and using renewable energy sources to minimize their carbon footprint.

metallurgy factories

The production of alloys is another significant aspect of metallurgy. Alloys, which are mixtures of two or more metals, possess enhanced properties compared to their base metals. For instance, stainless steel, an alloy of iron, chromium, and nickel, offers superior corrosion resistance and strength, making it ideal for various applications ranging from kitchen utensils to industrial machinery. Metallurgy factories invest heavily in research and development to create new alloys that meet the evolving needs of industries, helping them to innovate and improve their products.

Moreover, metallurgy factories are equipped with advanced technology and machinery, such as automated casting systems and high-precision machining tools. These technological advancements not only improve efficiency but also ensure the consistent quality of metal products. Automation and computerization in manufacturing processes also enable real-time monitoring and control, reducing waste and enhancing productivity.

In addition to producing metals and alloys, metallurgy factories support local economies by providing jobs and contributing to the industrial ecosystem. Skilled workers, engineers, and scientists collaborate in these facilities, driving innovation and maintaining high production standards.

In conclusion, metallurgy factories are indispensable to modern industry. They not only provide the fundamental materials needed for various sectors but also contribute to technological advancements and economic growth. As the world moves towards more sustainable practices, these factories will continue to evolve, adopting greener technologies and practices to meet the demands of the future. Emphasizing recycling, innovation, and efficiency will ensure that metallurgy remains a vital component of the global economy.

-

Eco-Friendly Granule Covering Agent | Dust & Caking Control

NewsAug.06,2025

-

Fe-C Composite Pellets for BOF: High-Efficiency & Cost-Saving

NewsAug.05,2025

-

Premium Tundish Covering Agents Exporters | High Purity

NewsAug.04,2025

-

Fe-C Composite Pellets for BOF | Efficient & Economical

NewsAug.03,2025

-

Top Tundish Covering Agent Exporters | Premium Quality Solutions

NewsAug.02,2025

-

First Bauxite Exporters | AI-Optimized Supply

NewsAug.01,2025