Dec . 29, 2024 10:57 Back to list

Innovative Combinations of Metals for Enhanced Manufacturing Solutions in Metallurgy

Understanding Metallurgy Exploring the World of Metal Combinations in Manufacturing

Metallurgy, the science and technology of metals, plays a crucial role in various industries, shaping the products we use every day. Among its several branches, the study of metal combinations, or alloys, is of paramount importance. This article delves into the significance of metal combinations, their manufacturing processes, and their applications in the modern world.

The Basics of Metallurgy and Alloys

Metallurgy is an interdisciplinary field that encompasses physical and chemical properties of metals, the processes involved in metallurgy, and the design of metal products. At its core, metallurgy focuses on understanding how different metals can be combined to produce alloys with specific characteristics. An alloy is a mixture of two or more elements, with at least one being a metal. Common examples of alloys include bronze (copper and tin) and stainless steel (iron, carbon, and chromium).

The combination of metals can significantly enhance their properties, such as strength, ductility, and corrosion resistance. These enhancements allow for the creation of materials that can withstand harsher environments or load demands than their base metals, making alloys indispensable in various applications.

Manufacturing Metal Combinations

In the manufacturing context, creating metal combinations involves various techniques. One prevalent method is alloying, which can be achieved through processes like melting and casting, powder metallurgy, and mechanical alloying.

1. Melting and Casting This traditional method involves melting the base metals together to achieve a homogenous mixture. The molten alloy is then poured into molds, where it solidifies into desired shapes. This method is popular for mass production of industrially significant metals.

2. Powder Metallurgy This method involves compressing metal powders into a desired shape and then heating them to cause sintering. This process is advantageous for creating complex shapes and allows for a high degree of precision, making it ideal for manufacturing parts in aerospace and automotive industries.

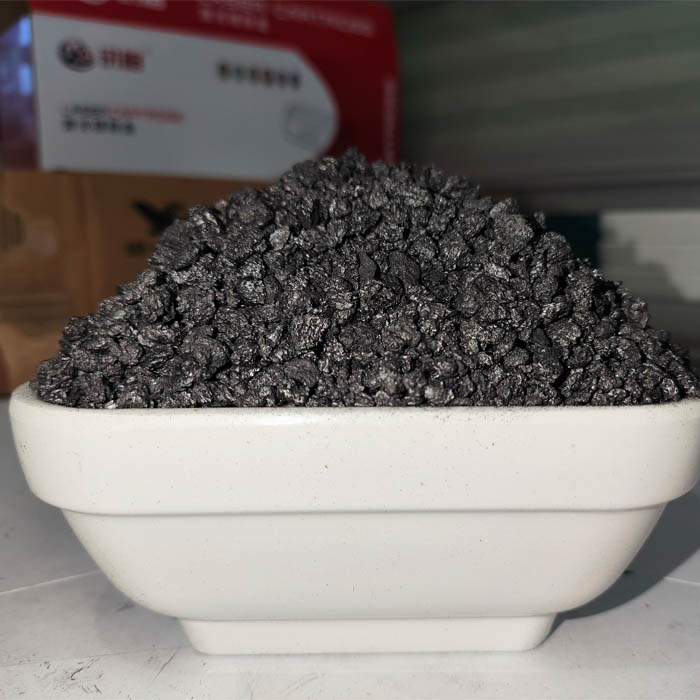

metallurgy 4 metal combinations manufacturer

3. Mechanical Alloying This technique involves repeatedly cold welding and fracturing powder particles in a high-energy ball mill. The method effectively produces materials with unique properties, suitable for specialized applications such as high-performance structural components.

Applications of Metal Combinations

The applications of metal combinations are vast and varied. Alloys are fundamental in the automotive, aerospace, construction, and electronics sectors. For instance, in the automotive industry, steel alloys are used for manufacturing frames and body panels due to their high strength-to-weight ratio. In the aerospace sector, lightweight aluminum alloys are critical for reducing fuel consumption while maintaining structural integrity.

Furthermore, alloys like 316 stainless steel, known for its corrosion resistance, are frequently used in marine environments and in the food and pharmaceutical industries for their hygiene and safety standards.

The Future of Metallurgy and Metal Combinations

Recent advancements in metallurgy, such as the development of high-entropy alloys and smart materials, promise to revolutionize the field further. High-entropy alloys consist of multiple principal elements, providing extraordinary mechanical properties that could lead to lighter and stronger materials for several applications, from transport to renewable energy technologies.

Moreover, the integration of digital technologies, including data analytics and artificial intelligence, is shaping the future of metal combination manufacturing. These technologies facilitate better prediction of material properties and optimize production processes, leading to more efficient and sustainable manufacturing methods.

Conclusion

In conclusion, the world of metallurgy and metal combinations is a dynamic field with significant implications for various industries. As we continue to innovate and explore new combinations of metals, the potential for creating stronger, lighter, and more versatile materials is only set to grow. Understanding and leveraging the characteristics of metal alloys will remain vital for driving advancements in manufacturing and enhancing product performance across numerous applications.

-

Fe-C Composite Pellets for BOF: Enhance Steelmaking Efficiency

NewsAug.07,2025

-

Eco-Friendly Granule Covering Agent | Dust & Caking Control

NewsAug.06,2025

-

Fe-C Composite Pellets for BOF: High-Efficiency & Cost-Saving

NewsAug.05,2025

-

Premium Tundish Covering Agents Exporters | High Purity

NewsAug.04,2025

-

Fe-C Composite Pellets for BOF | Efficient & Economical

NewsAug.03,2025

-

Top Tundish Covering Agent Exporters | Premium Quality Solutions

NewsAug.02,2025