Aug . 30, 2024 09:30 Back to list

Non-Bubbling Refractory Materials Supplier - High-Quality Heat-Resistant Solutions

Non-Bubbling Refractory Material Supplier A Guide to Quality and Performance

In the world of industrial applications, the demand for durable and heat-resistant materials has led to the emergence of specialized suppliers focusing on non-bubbling refractory materials. These materials are essential for industries where high temperatures and thermal stability are crucial, such as steelmaking, cement production, and glass manufacturing.

Understanding Non-Bubbling Refractory Materials

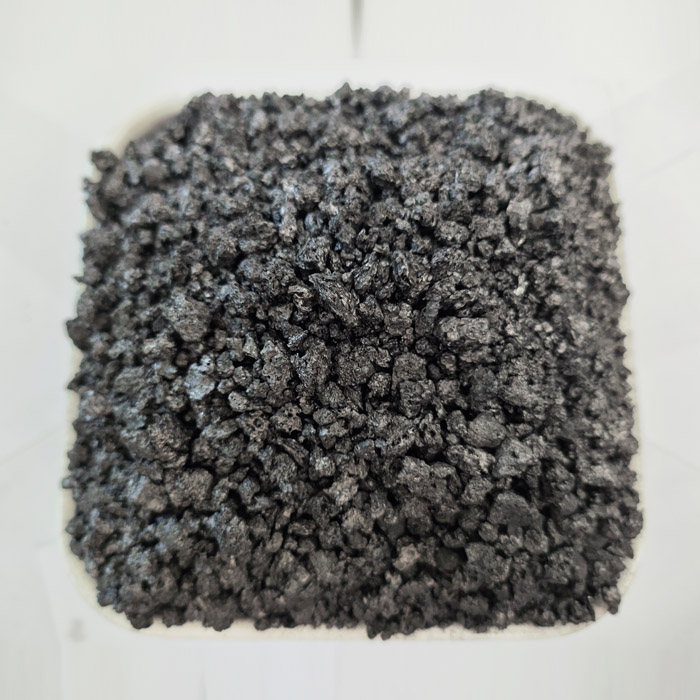

Non-bubbling refractories are designed to withstand extreme temperatures without undergoing significant expansion or deformation. This characteristic is particularly important in environments where thermal shock can occur, such as in furnaces and kilns. Unlike traditional refractories that may develop bubbles or voids when heated, non-bubbling materials maintain their structural integrity, ensuring consistent performance over time.

This class of refractory materials is typically composed of high-purity alumina and other additives that enhance their resistance to wear and chemical attack. As a result, non-bubbling refractories are highly favored in applications that require long-lasting durability and reliability.

The Role of Suppliers

Not all suppliers are created equal. When searching for a reputable non-bubbling refractory material supplier, several factors should be considered. Quality assurance is paramount; suppliers should provide materials that meet industry standards and specifications. This can often be verified through certifications or third-party testing.

non bubbling refractory material supplier

In addition to product quality, the supplier's experience and expertise in the field also matter. A seasoned supplier will not only offer a range of high-quality products but will also provide valuable insights regarding material selection, application techniques, and troubleshooting strategies.

Product Range and Customization

A reliable non-bubbling refractory supplier will offer an extensive product range, including castables, bricks, and precast shapes tailored for various applications. Furthermore, the ability to customize materials to meet specific operational conditions or customer requirements is an added advantage. This customization can encompass variables such as density, thermal conductivity, and chemical composition, ensuring optimal performance for the intended application.

Technical Support and Services

Beyond product supply, technical support plays a critical role in the relationship between suppliers and their customers. The best suppliers offer consultation services to help clients select the right materials for their specific needs, as well as ongoing support during installation and operation. This commitment to customer service leads to improved efficiency, reduced downtime, and enhanced overall performance.

Conclusion

In conclusion, selecting the right non-bubbling refractory material supplier can significantly impact the efficiency and longevity of industrial processes. As industries continue to evolve, suppliers who prioritize quality, innovation, and customer service will stand out. By partnering with a trusted refractory supplier, businesses can ensure they are equipped with the necessary materials to thrive in high-temperature environments.

-

Eco-Friendly Granule Covering Agent | Dust & Caking Control

NewsAug.06,2025

-

Fe-C Composite Pellets for BOF: High-Efficiency & Cost-Saving

NewsAug.05,2025

-

Premium Tundish Covering Agents Exporters | High Purity

NewsAug.04,2025

-

Fe-C Composite Pellets for BOF | Efficient & Economical

NewsAug.03,2025

-

Top Tundish Covering Agent Exporters | Premium Quality Solutions

NewsAug.02,2025

-

First Bauxite Exporters | AI-Optimized Supply

NewsAug.01,2025