Sep . 25, 2024 16:15 Back to list

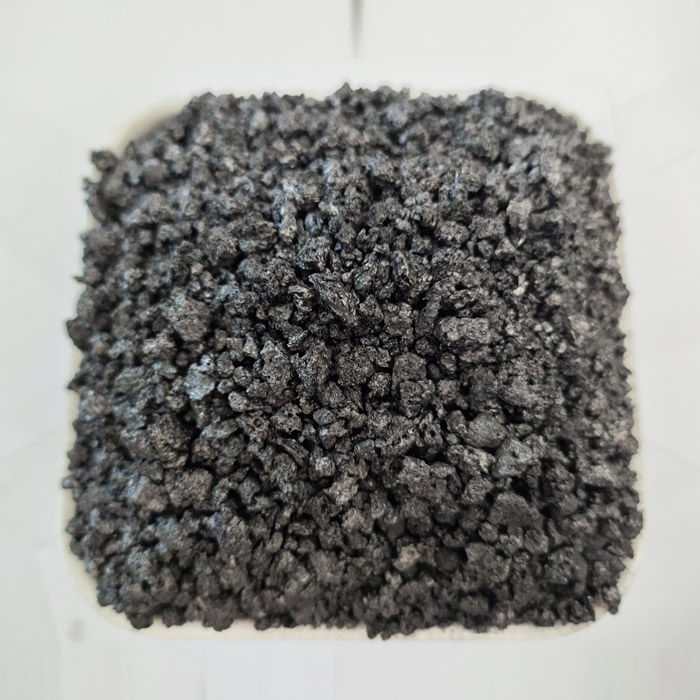

oxidative resistance factory

The Role of Oxidative Resistance in Factory Settings Enhancing Longevity and Efficiency

In the modern industrial landscape, factories play a crucial role in the production of goods that fuel economies worldwide. As we delve deeper into the mechanics of factory operations, one increasingly significant aspect has emerged oxidative resistance. This concept encompasses the ability of materials, machinery, and processes to withstand oxidative stress, a phenomenon that can culminate in the deterioration of equipment and a decrease in overall efficiency. This article explores the importance of oxidative resistance in factory environments, its implications for longevity and efficiency, and the strategies to enhance it.

Understanding Oxidative Stress

Oxidative stress occurs when there is an imbalance between free radicals and antioxidants in the body or a system. In a factory setting, free radicals are often generated through high-temperature operations, chemical reactions, and the breakdown of organic materials. These reactive species can cause significant damage to the metal surfaces of machinery, leading to corrosion, wear, and tear. This degradation can severely impact productivity and safety in industrial operations.

Implications of Oxidative Resistance

The oxidative resistance of materials and equipment is critical for several reasons

1. Longevity of Equipment Factories rely on complex machinery to perform various tasks, from assembly lines to heavy-duty manufacturing. When equipment is resistant to oxidative stress, it tends to have a longer lifespan, reducing the frequency and costs associated with repairs and replacements.

2. Operational Efficiency A reduction in machinery downtime due to oxidation-related failures translates directly to increased operational efficiency. The smooth and uninterrupted functioning of equipment ensures that production targets are met consistently.

3. Safety Oxidative damage can lead to catastrophic failures in machinery, posing significant safety risks to employees. By enhancing oxidative resistance, factories can create a safer working environment, thus protecting their workforce from potential hazards.

4. Environmental Impact Factories are increasingly held accountable for their environmental footprints. Equipment that is more resistant to oxidative degradation is typically more energy-efficient, resulting in lower emissions and waste by-products. This aligns with the global push towards sustainability and responsible manufacturing.

oxidative resistance factory

Strategies to Enhance Oxidative Resistance

To leverage the benefits of oxidative resistance, factories can adopt several strategies

1. Material Selection Choosing the right materials is crucial. For example, stainless steel and certain alloys exhibit superior resistance to oxidative stress compared to standard metals. By investing in quality materials for machinery and production components, factories can greatly enhance their oxidative resistance.

2. Protective Coatings Applying specialized coatings on machinery parts and surfaces can provide an additional barrier against oxidative agents. These coatings can prevent moisture and harmful chemicals from contacting the underlying material, thereby prolonging its life.

3. Regular Maintenance Implementing a proactive maintenance schedule can significantly reduce oxidative damage. Regular inspections, cleaning, and repairs help identify issues before they escalate, ensuring that machinery operates at optimal efficiency.

4. Innovation and Technology The use of advanced technologies, such as predictive maintenance and real-time monitoring systems, can help factories keep track of the oxidative state of their machinery. By employing sensors and data analytics, operators can anticipate failures and take corrective actions before significant damage occurs.

5. Employee Training Educating employees about the factors contributing to oxidative stress and best practices for maintenance can empower them to play an active role in enhancing oxidative resistance. A well-informed workforce is instrumental in ensuring the longevity and efficiency of factory operations.

Conclusion

As industries continue to evolve, the importance of oxidative resistance in factory settings cannot be overstated. By understanding and enhancing the oxidative resistance of machinery and equipment, factories can ensure not only the longevity of their assets but also significant improvements in operational efficiency and workplace safety. Investing in this area not only benefits the factory's bottom line but also aligns with broader sustainability goals, making it a critical focus for modern industrial operations. In a world increasingly driven by efficiency and environmental consciousness, embracing oxidative resistance is not just an option; it is a necessity.

-

Eco-Friendly Granule Covering Agent | Dust & Caking Control

NewsAug.06,2025

-

Fe-C Composite Pellets for BOF: High-Efficiency & Cost-Saving

NewsAug.05,2025

-

Premium Tundish Covering Agents Exporters | High Purity

NewsAug.04,2025

-

Fe-C Composite Pellets for BOF | Efficient & Economical

NewsAug.03,2025

-

Top Tundish Covering Agent Exporters | Premium Quality Solutions

NewsAug.02,2025

-

First Bauxite Exporters | AI-Optimized Supply

NewsAug.01,2025