Aug . 31, 2024 09:38 Back to list

Premium Pipe Insulation Cladding Materials - Durable & Energy Efficient Solutions

A Comprehensive Overview of Pipe Insulation Cladding Materials Factories and Their Significance

In the construction and industrial sectors, the efficiency and sustainability of energy systems are paramount. One crucial aspect of this is the proper insulation of pipes, which plays a significant role in minimizing energy loss, preventing condensation, and protecting sensitive materials from environmental factors. The manufacturing of pipe insulation cladding materials has become essential as industries seek to enhance their energy efficiency and reduce operational costs.

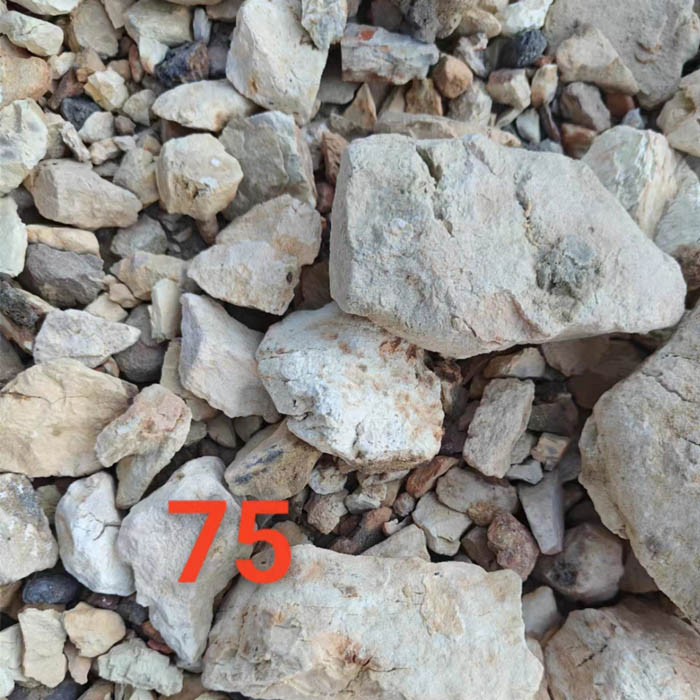

Pipe insulation cladding materials can include a variety of substances, such as fiberglass, polyethylene, rubber, and metal. Each of these materials has unique properties that cater to different applications. Fiberglass, for instance, is widely used for its high thermal resistance and lightweight nature. It is particularly effective for high-temperature applications, making it a go-to choice for steam lines and hot water pipes. Conversely, polyethylene offers excellent moisture resistance, making it suitable for outdoor applications and areas prone to humidity.

Factories that produce these insulation materials focus on advanced manufacturing techniques to ensure quality and efficiency. They utilize state-of-the-art machinery and adhere to stringent safety and environmental regulations. The manufacturing process typically involves the following stages raw material selection, mixing, forming, curing, and finishing. Each step is crucial in determining the final product's effectiveness and durability.

pipe insulation cladding materials factories

One of the key factors driving the demand for high-quality insulation cladding materials is the increasing awareness of energy conservation and environmental sustainability. Industries are progressively looking for ways to reduce their carbon footprint, and effective pipe insulation can contribute significantly to this goal. By minimizing heat loss, insulated pipes require less energy for heating and cooling, which can lead to substantial cost savings over time.

Moreover, the building code regulations in many regions are becoming more stringent regarding thermal insulation requirements. This has prompted factories to innovate and develop new materials that not only meet these regulations but also provide enhanced performance characteristics. For instance, some manufacturers are investing in eco-friendly insulation materials that are made from recycled or sustainable sources. This aligns with the global trend towards sustainability and environmentally responsible manufacturing.

The industry is also benefiting from technological advancements that allow for better customization of insulation products. Factories can now produce cladding materials tailored to specific applications, whether it involves unique shapes, sizes, or performance characteristics. This level of customization ensures that clients receive the most efficient and effective products for their specific needs.

In conclusion, the significance of pipe insulation cladding materials cannot be overstated. They play a crucial role in energy efficiency, cost reduction, and environmental protection across various industries. The ongoing advancements in manufacturing technologies and an increasing focus on sustainable practices are set to propel the growth of this sector. As factories continue to evolve and adapt to the changing market demands, the future of pipe insulation materials looks promising, paving the way for enhanced industrial efficiency and sustainable practices.

-

Eco-Friendly Granule Covering Agent | Dust & Caking Control

NewsAug.06,2025

-

Fe-C Composite Pellets for BOF: High-Efficiency & Cost-Saving

NewsAug.05,2025

-

Premium Tundish Covering Agents Exporters | High Purity

NewsAug.04,2025

-

Fe-C Composite Pellets for BOF | Efficient & Economical

NewsAug.03,2025

-

Top Tundish Covering Agent Exporters | Premium Quality Solutions

NewsAug.02,2025

-

First Bauxite Exporters | AI-Optimized Supply

NewsAug.01,2025