Feb . 14, 2025 17:59 Back to list

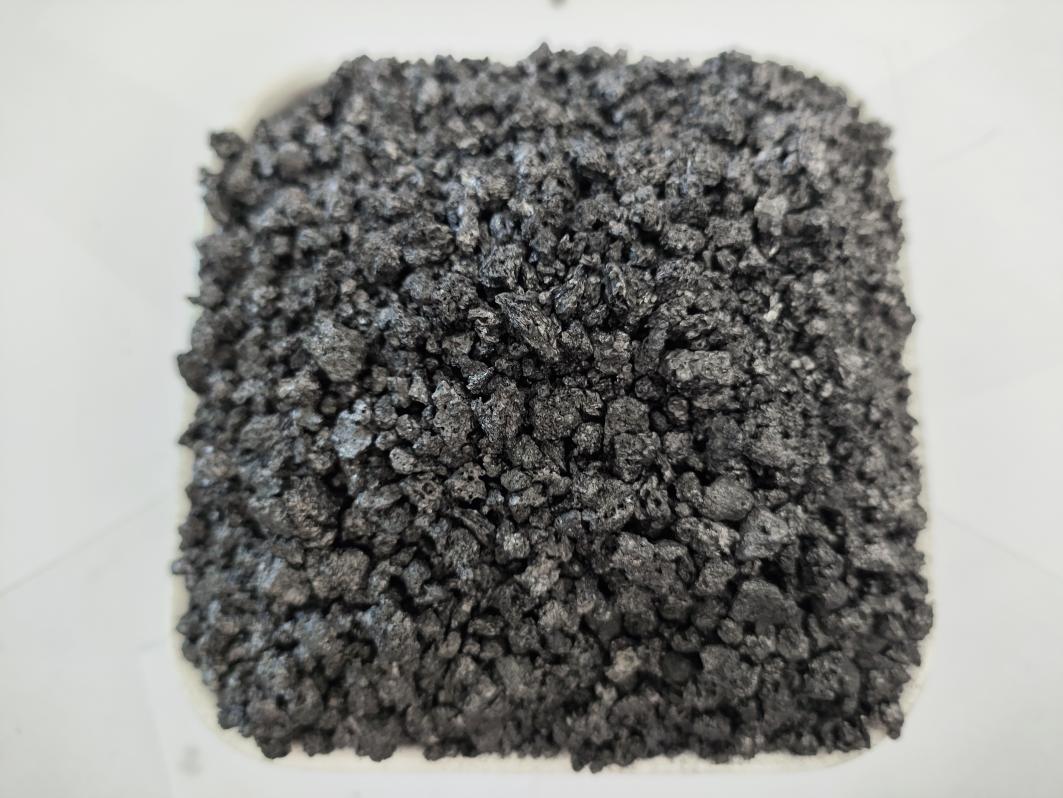

Tundish Dry Vibration Material

In the realm of industrial projects and residential systems, choosing the right piping insulation material is vital for both efficiency and safety. The complexity and variety of insulation materials require a comprehensive understanding to make an informed choice. This article delves into distinct types of piping insulation materials, emphasizing their properties, applications, and benefits while addressing key industry standards and practices.

Polyisocyanurate and phenolic foam bring in a higher degree of insulation due to their lower thermal conductivity. They are incredibly efficient for extreme temperatures found in industrial applications. Despite their greater cost, the reduced material requirement for achieving similar insulative results can justify their use in high-performance scenarios. In addition to selecting the suitable material, compliance with regulatory standards such as those provided by the ASTM, ASHRAE, or specific national standards is non-negotiable. Employing materials that meet certified specifications not only ensures safety but can also enhance system reliability and longevity. The reliability of an insulation material is further influenced by the installation process. Even the most advanced materials can fail to perform if not installed correctly. Expert guidance and adherence to installation protocols are critical to maximize the effectiveness and lifespan of the insulating material. In summary, the choice of piping insulation materials revolves around understanding distinct project needs and selecting materials that align with operational conditions, regulatory standards, and sustainability goals. Each material, from fiberglass to phenolic foam, offers unique advantages and must be chosen after careful assessment of its compatibility with the intended application to optimize performance and cost-efficiency. Concluding with authority and trust, professionals in the field must remain abreast of advancements in insulation technology to provide informed strategies that promote operational efficiency, safety, and sustainability. Informed decisions not only enhance system performance but also contribute to responsible resource management and environmental stewardship.

Polyisocyanurate and phenolic foam bring in a higher degree of insulation due to their lower thermal conductivity. They are incredibly efficient for extreme temperatures found in industrial applications. Despite their greater cost, the reduced material requirement for achieving similar insulative results can justify their use in high-performance scenarios. In addition to selecting the suitable material, compliance with regulatory standards such as those provided by the ASTM, ASHRAE, or specific national standards is non-negotiable. Employing materials that meet certified specifications not only ensures safety but can also enhance system reliability and longevity. The reliability of an insulation material is further influenced by the installation process. Even the most advanced materials can fail to perform if not installed correctly. Expert guidance and adherence to installation protocols are critical to maximize the effectiveness and lifespan of the insulating material. In summary, the choice of piping insulation materials revolves around understanding distinct project needs and selecting materials that align with operational conditions, regulatory standards, and sustainability goals. Each material, from fiberglass to phenolic foam, offers unique advantages and must be chosen after careful assessment of its compatibility with the intended application to optimize performance and cost-efficiency. Concluding with authority and trust, professionals in the field must remain abreast of advancements in insulation technology to provide informed strategies that promote operational efficiency, safety, and sustainability. Informed decisions not only enhance system performance but also contribute to responsible resource management and environmental stewardship.

Latest news

-

Top Tundish Covering Agent Exporters | Premium Quality Solutions

NewsAug.02,2025

-

First Bauxite Exporters | AI-Optimized Supply

NewsAug.01,2025

-

Low Nitrogen Graphitized Petroleum Coke Supplier

NewsJul.31,2025

-

Premium Vermiculite Soil Exporters - Boost Plant Growth

NewsJul.31,2025

-

Premium Building Material for Round Wall Exporters, Manufacturers & Suppliers

NewsJul.30,2025

-

Top Carbon Petroleum Coke Exporters – Reliable Quality & Fast Delivery

NewsJul.30,2025