Nov . 16, 2024 15:51 Back to list

Factories Producing Insulation Materials for Piping Systems and Their Applications

Piping Insulation Materials An Overview of Factories and Their Significance

In industrial settings, the importance of piping insulation materials cannot be overstated. These materials are critical in maintaining the efficiency of piping systems, preventing heat loss or gain, and ensuring safety in various applications. As industries continue to grow and evolve, the demand for high-quality insulating materials produced by specialized factories has surged.

Piping Insulation Materials An Overview of Factories and Their Significance

Factories that specialize in the production of piping insulation materials utilize advanced technologies and materials to meet diverse industrial needs. Common insulation materials include fiberglass, mineral wool, foam, and polyethylene. Each of these materials has unique properties that cater to specific applications. For example, fiberglass is renowned for its thermal resistance and is often used in high-temperature environments, while foam insulations provide excellent moisture resistance, making them suitable for HVAC systems.

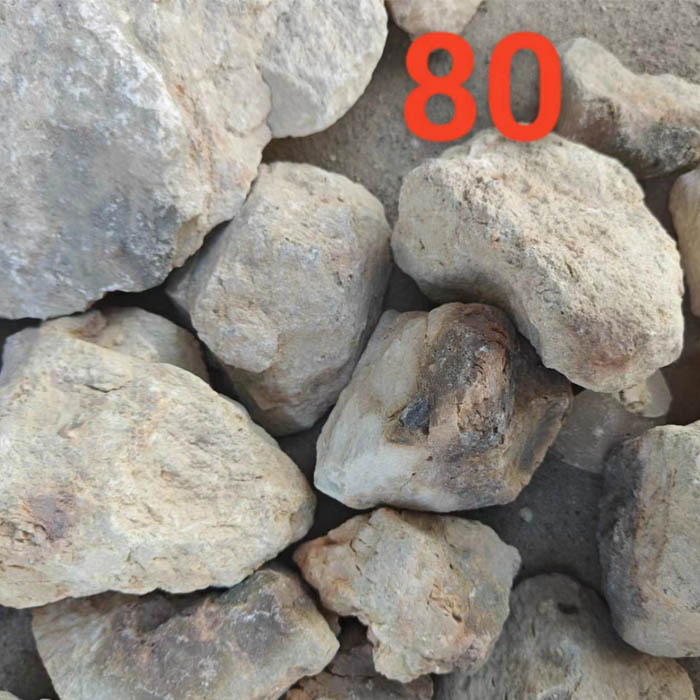

piping insulation materials factories

The manufacturing process in factories typically involves several stages, including material selection, shaping, and quality control. Manufacturers invest heavily in research and development to innovate and optimize insulation solutions. This focus on quality ensures that their products comply with industry standards and regulations, which is vital for maintaining safety and efficiency in operations.

Moreover, factories are increasingly adopting sustainable practices in their production processes. With a growing emphasis on green technology, many insulation manufacturers are sourcing recycled materials and developing bio-based insulation products. These initiatives not only minimize environmental impact but also cater to the expanding market of eco-conscious consumers and companies seeking sustainable building solutions.

Beyond production, the supply chain plays a crucial role in the effectiveness of piping insulation. Factories often collaborate closely with distributors, contractors, and end-users to understand their specific insulation needs and tailor products accordingly. This collaboration ensures that the selected insulation material is suitable for the intended application, whether it’s for residential, commercial, or industrial use.

In conclusion, factories producing piping insulation materials are pivotal in supporting energy efficiency, safety, and environmental sustainability across various industries. As demand continues to grow, innovation in materials and processes will remain paramount. Through ongoing collaboration and a commitment to quality, these factories will play a crucial role in shaping the future of piping insulation, ensuring that industries can operate effectively while minimizing their ecological footprint. Ensuring that the insulation materials are adequate for high-performance applications will be essential as industries strive for greater productivity in an increasingly competitive landscape.

-

Eco-Friendly Granule Covering Agent | Dust & Caking Control

NewsAug.06,2025

-

Fe-C Composite Pellets for BOF: High-Efficiency & Cost-Saving

NewsAug.05,2025

-

Premium Tundish Covering Agents Exporters | High Purity

NewsAug.04,2025

-

Fe-C Composite Pellets for BOF | Efficient & Economical

NewsAug.03,2025

-

Top Tundish Covering Agent Exporters | Premium Quality Solutions

NewsAug.02,2025

-

First Bauxite Exporters | AI-Optimized Supply

NewsAug.01,2025