Aug . 29, 2024 05:34 Back to list

Thermal Insulation Materials Exporters - Quality Products & Competitive Prices

The Price of Thermal Insulation Materials for Exporters A Comprehensive Overview

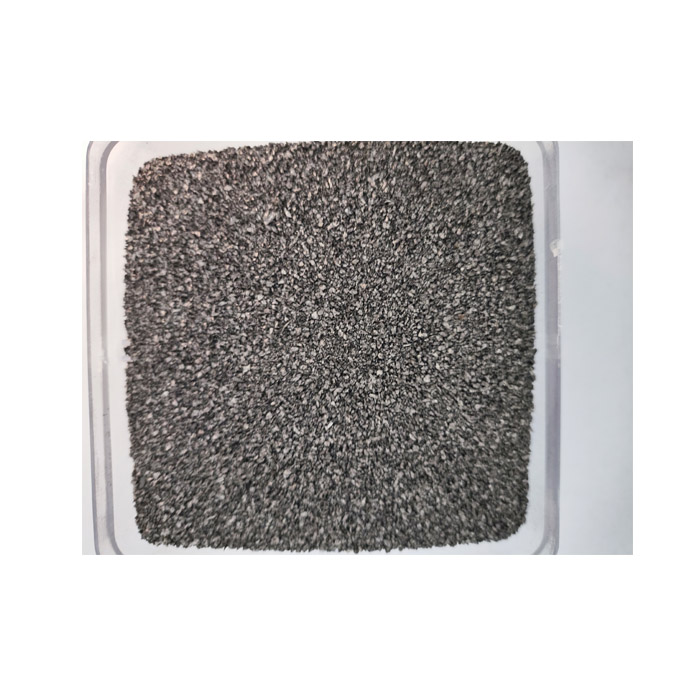

Thermal insulation materials play a crucial role in enhancing energy efficiency and reducing costs across various industries. For exporters of these materials, understanding pricing dynamics is essential not only for competitiveness but also for ensuring profitability in a global market characterized by fluctuating demand and supply chains.

The prices of thermal insulation materials can vary significantly based on several factors, including raw material costs, manufacturing processes, and market demand

. Common thermal insulation materials such as fiberglass, foam, and mineral wool each come with distinct pricing structures influenced by the type of application, thermal performance, and durability requirements.One of the primary drivers of pricing is the cost of raw materials. For instance, the price of petrochemical-derived products, which are used to manufacture foam insulation, can be subject to volatility due to fluctuations in crude oil prices. In contrast, natural fiber insulation materials often rely on agricultural outputs, which can be impacted by seasonal changes and climate conditions. Exporters must keep a close eye on these factors as they can significantly affect pricing strategies and ultimately the bottom line.

price of thermal insulation materials exporters

Additionally, advancements in technology and manufacturing methods can lead to changes in production costs and efficiencies. Exporters who invest in sustainable production methods and innovative materials can potentially offer superior products at competitive prices, which can help capture a growing segment of eco-conscious clients in the global market.

Furthermore, regional market conditions also influence pricing. In regions where energy efficiency regulations are stringent, demand for high-quality insulation materials tends to be higher, driving prices up. Conversely, in markets where regulations are lax, or where cheaper alternatives dominate, exporters may face pricing pressures, forcing them to reduce margins to maintain market share.

Another consideration for exporters is the logistics of transportation. Shipping costs can add significantly to the final price of thermal insulation materials, especially given fluctuating fuel prices and potential trade barriers. Exporters must strategize to minimize these costs, which may involve optimizing supply chains and adjusting pricing according to different markets.

In summary, the price of thermal insulation materials for exporters is influenced by multiple interconnected factors, including raw material costs, manufacturing processes, regional demand, and logistics. To remain competitive and sustainable, exporters must continuously analyze these variables, adapt their strategies accordingly, and seek opportunities for innovation. As the global emphasis on energy efficiency and sustainability continues to rise, the market for thermal insulation materials is expected to grow, presenting both challenges and opportunities for exporters in the industry. By staying informed and agile, they can navigate this dynamic market landscape effectively.

-

Eco-Friendly Granule Covering Agent | Dust & Caking Control

NewsAug.06,2025

-

Fe-C Composite Pellets for BOF: High-Efficiency & Cost-Saving

NewsAug.05,2025

-

Premium Tundish Covering Agents Exporters | High Purity

NewsAug.04,2025

-

Fe-C Composite Pellets for BOF | Efficient & Economical

NewsAug.03,2025

-

Top Tundish Covering Agent Exporters | Premium Quality Solutions

NewsAug.02,2025

-

First Bauxite Exporters | AI-Optimized Supply

NewsAug.01,2025