Oct . 06, 2024 08:23 Back to list

primary steel making supplier

The Importance of Primary Steel Making Suppliers in Modern Industry

Primary steel making is a critical process in the steel industry, serving as the foundational stage for producing high-quality steel products essential for various applications, from construction to automotive manufacturing. The role of primary steel making suppliers is integral to this process, impacting not only the quality of the steel produced but also the efficiency and sustainability of the entire supply chain.

Understanding Primary Steel Making

The primary steel making process primarily involves converting raw materials into molten steel. This typically occurs in two main types of furnaces the Basic Oxygen Furnace (BOF) and the Electric Arc Furnace (EAF). In the BOF process, iron ore, coke, and lime are introduced into a converter, where oxygen is blown in to oxidize impurities, creating molten steel and slag. On the other hand, the EAF process utilizes recycled scrap metal, melting it down with electric arcs to produce new steel. Both methods require high-quality raw materials and a reliable supply chain to ensure consistent output and product quality.

The Role of Suppliers

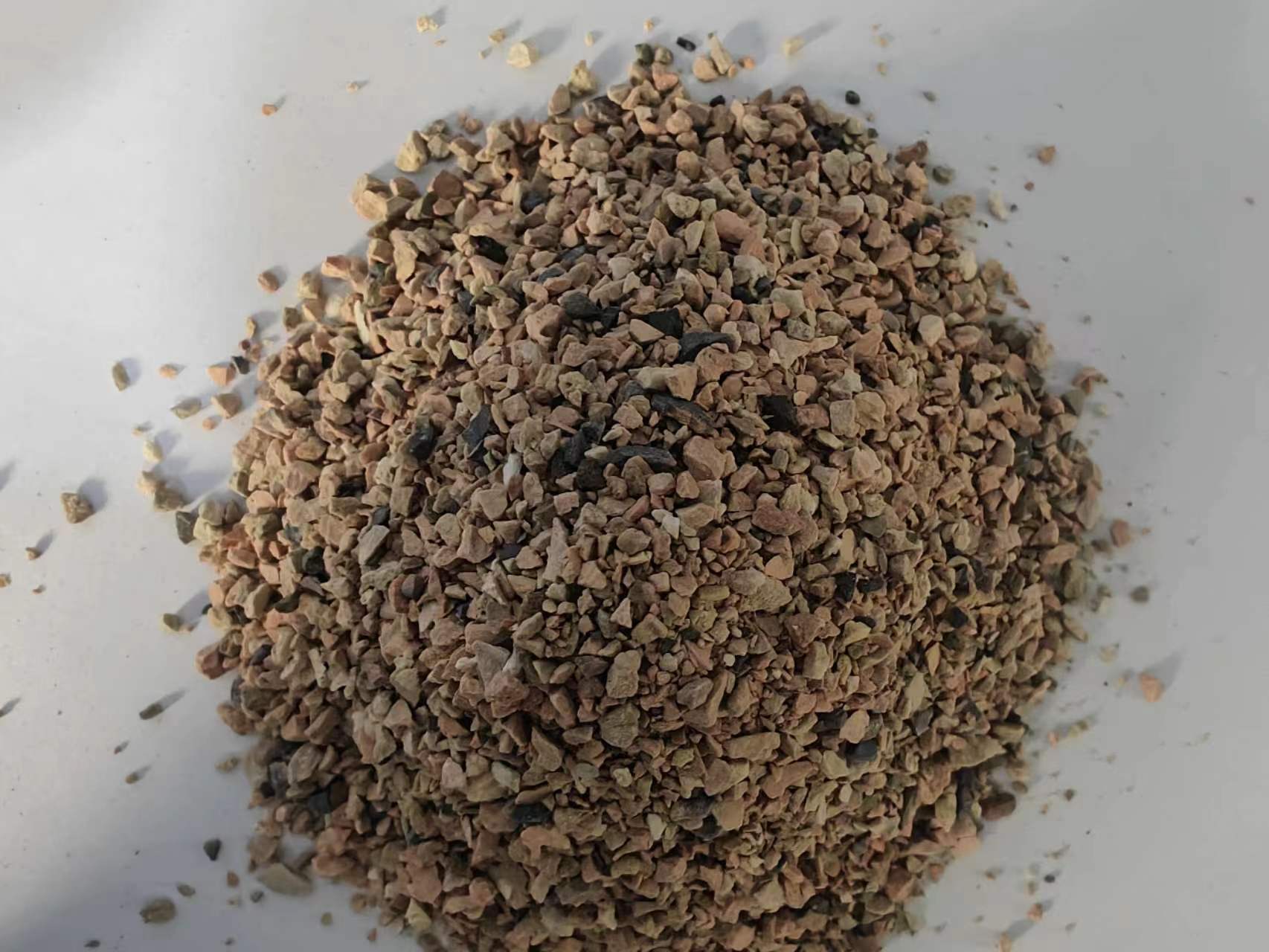

Primary steel making suppliers provide the essential raw materials needed for the production process. These include iron ore, scrap steel, coke, and various alloys. Reliable suppliers are vital, as fluctuations in quality or delivery schedules can severely disrupt the steel production process. Suppliers also play a significant role in maintaining sustainable practices, offering environmentally friendly materials and technologies that help steel producers reduce their carbon footprint.

Quality Assurance

primary steel making supplier

Quality is paramount in steel production, as the properties of the finished product - such as tensile strength, ductility, and resistance to corrosion - depend heavily on the quality of raw materials. Primary steel making suppliers must adhere to stringent industry standards and certifications, ensuring that their materials meet specific chemical and physical requirements. This focus on quality not only affects the durability and safety of the final products but also impacts the overall reputation and competitiveness of steel manufacturers in the market.

Technological Advancements

With advancements in technology, the relationship between primary steel making suppliers and steel manufacturers has evolved. Suppliers are increasingly utilizing data analytics and automated systems to optimize their operations. This not only helps in maintaining quality but also enhances efficiency, reducing lead times and costs. Collaboration with suppliers in adopting new technologies can lead to innovative solutions that benefit both parties and contribute to the overall improvement of the steel production process.

Sustainability in Steel Making

As the world shifts towards more sustainable practices, the role of primary steel making suppliers is more crucial than ever. Suppliers are embracing eco-friendly approaches by sourcing materials from sustainable sources, investing in recycling and waste management practices, and developing lower-carbon products. Steel manufacturers who partner with such suppliers can significantly enhance their sustainability profile, responding to growing demand from consumers and regulators for greener practices.

Conclusion

In conclusion, primary steel making suppliers are indispensable to the steel industry. They ensure the availability of high-quality raw materials, contribute to the efficiency of production processes, maintain stringent quality standards, adopt technological advancements, and embrace sustainability. As industries worldwide continue to evolve, the importance of forging strategic partnerships with reliable primary steel making suppliers will only continue to grow, shaping the future of steel manufacturing and numerous related sectors. By recognizing and nurturing these relationships, steel manufacturers can pave the way for a more resilient, sustainable, and innovative industry.

-

Fe-C Composite Pellets for BOF: Enhance Steelmaking Efficiency

NewsAug.07,2025

-

Eco-Friendly Granule Covering Agent | Dust & Caking Control

NewsAug.06,2025

-

Fe-C Composite Pellets for BOF: High-Efficiency & Cost-Saving

NewsAug.05,2025

-

Premium Tundish Covering Agents Exporters | High Purity

NewsAug.04,2025

-

Fe-C Composite Pellets for BOF | Efficient & Economical

NewsAug.03,2025

-

Top Tundish Covering Agent Exporters | Premium Quality Solutions

NewsAug.02,2025