Dec . 09, 2024 18:21 Back to list

Properties and Applications of Reduced Iron Powder in Various Industries

The Significance of Reduced Iron Powder in Modern Industries

Reduced iron powder, a fine iron powder that has been processed to remove impurities and oxygen, plays a crucial role in various industrial applications. With its unique properties and advantages, this material is pivotal in enhancing the performance of many products, bridging gaps in efficiency, quality, and sustainability.

Reduced iron powder is primarily produced through the reduction of iron oxide, which is commonly derived from iron ore. This method involves the use of reducing agents such as hydrogen or carbon monoxide at elevated temperatures, resulting in the transformation of oxidized iron into metallic iron. The product exhibits several distinct characteristics, making it highly sought after in different sectors.

One of the most significant applications of reduced iron powder is in the production of powder metallurgy components. In this method, the iron powder is mixed with other metal powders, pressed into a desired shape, and then sintered at high temperatures. This process allows for the creation of complex geometrical shapes that would be difficult to achieve through traditional machining methods. Additionally, the final products often exhibit superior mechanical properties, such as enhanced strength, hardness, and wear resistance.

In recent years, the automotive and aerospace industries have increasingly turned to reduced iron powder for manufacturing critical components. The lightweight and high-strength characteristics of reduced iron enable the production of parts that contribute to fuel efficiency and overall vehicle performance. Furthermore, the ability to create intricate designs through powder metallurgy reduces material waste and supports environmentally-friendly manufacturing practices.

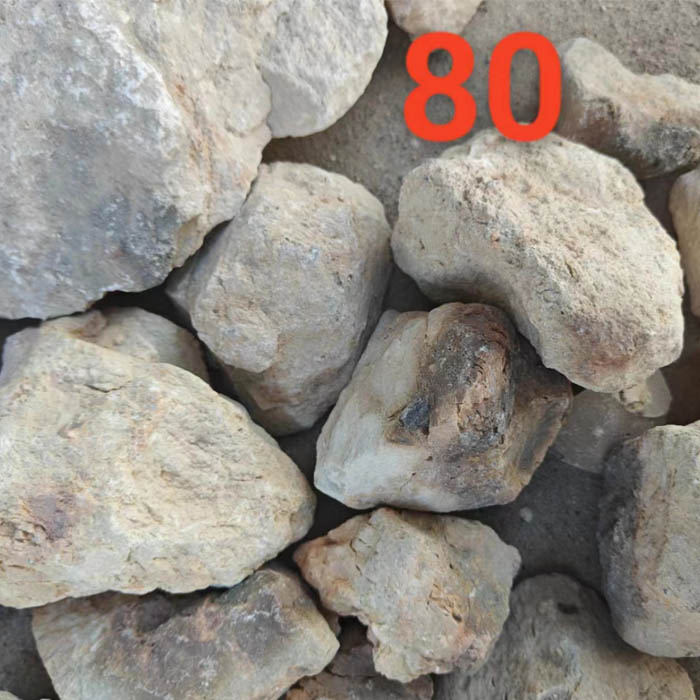

reduced iron powder

Another significant application of reduced iron powder is in the field of metallurgy and chemical industries. Used as a reducing agent in various chemical reactions, it facilitates the production of numerous alloys. Reduced iron powder also plays a valuable role in the production of magnetic materials, which are essential for electrical and electronic applications. The high magnetic permeability and low coercivity of reduced iron make it an ideal material for components like transformers, inductors, and electric motors.

Moreover, reduced iron powder has found its way into the realm of additive manufacturing, also known as 3D printing. As the industry moves toward more advanced fabrication techniques, the use of iron powder in creating intricate designs and structures is becoming increasingly prominent. This shift allows for rapid prototyping, reduced production times, and the ability to produce on-demand, thus minimizing inventory costs.

Sustainability is another crucial aspect of the growing interest in reduced iron powder. With increasing pressure on industries to adopt greener practices, reduced iron powder's recycling potential stands out. The production process can utilize scrap metal and by-products, thereby reducing overall material waste and energy consumption. This not only enhances the sustainability of manufacturing processes but also aligns with the global pursuit of a circular economy.

In conclusion, reduced iron powder is a vital component in modern manufacturing and industrial applications. Its unique properties and versatility make it an essential material for producing high-quality components across various sectors, from automotive to aerospace and beyond. As industries continue to seek innovative and sustainable solutions, the importance of reduced iron powder is poised to grow, driving advances in technology and production while supporting sustainable practices. The ongoing development and application of this material hold promise for a more efficient and environmentally-friendly industrial future.

-

Eco-Friendly Granule Covering Agent | Dust & Caking Control

NewsAug.06,2025

-

Fe-C Composite Pellets for BOF: High-Efficiency & Cost-Saving

NewsAug.05,2025

-

Premium Tundish Covering Agents Exporters | High Purity

NewsAug.04,2025

-

Fe-C Composite Pellets for BOF | Efficient & Economical

NewsAug.03,2025

-

Top Tundish Covering Agent Exporters | Premium Quality Solutions

NewsAug.02,2025

-

First Bauxite Exporters | AI-Optimized Supply

NewsAug.01,2025