Jun . 14, 2024 00:07 Back to list

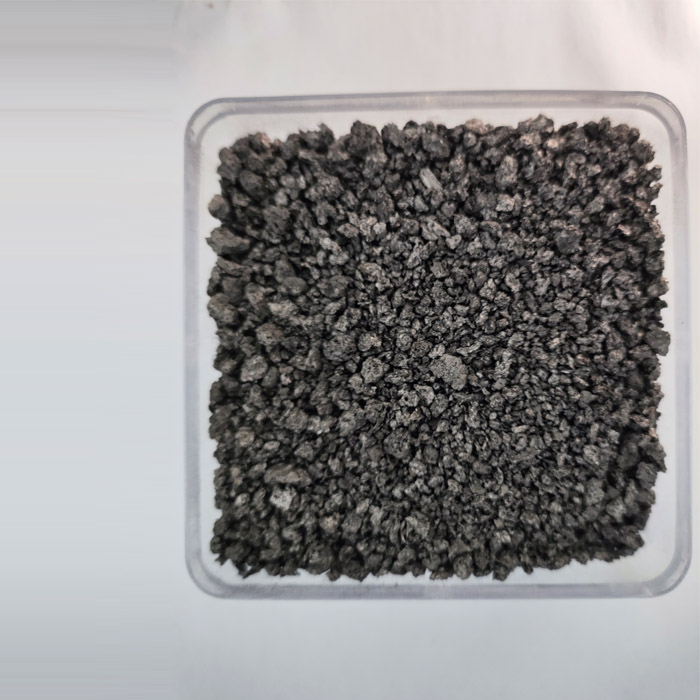

Refractory material for high-temperature investment casting

The Significance of Refractory Investment Materials in Modern Industry

Refractory investment materials, a critical component in high-temperature industrial processes, play an indispensable role in numerous sectors such as metallurgy, ceramics, glass manufacturing, and petrochemicals. These materials, characterized by their exceptional resistance to heat, wear, and chemical corrosion, are the backbone of many industries that rely on extreme thermal conditions for production.

The term 'refractory' refers to substances with a high melting point and excellent heat resistance, typically above 1580°C (3000°F). Investment materials, on the other hand, are those used to create molds or replicas of objects, often in casting processes. When these two concepts converge, they form refractory investment materials, which possess both durability under heat and precision in casting intricate shapes.

These materials are primarily composed of silica, alumina, zirconia, magnesia, and other refractory compounds. Their unique properties allow them to withstand the intense temperatures in furnaces, kilns, and other processing equipment without degrading or losing their structural integrity. They act as a protective barrier, maintaining the efficiency and longevity of the industrial equipment they line.

One of the key advantages of refractory investment materials is their versatility. They can be tailored to suit specific applications, with variations in composition to manage different temperature ranges, chemical exposures, and mechanical stresses. For instance, in the steel industry, they are used to line blast furnaces and ladles, protecting them from the aggressive environment created by molten iron and steel For instance, in the steel industry, they are used to line blast furnaces and ladles, protecting them from the aggressive environment created by molten iron and steel For instance, in the steel industry, they are used to line blast furnaces and ladles, protecting them from the aggressive environment created by molten iron and steel For instance, in the steel industry, they are used to line blast furnaces and ladles, protecting them from the aggressive environment created by molten iron and steel

For instance, in the steel industry, they are used to line blast furnaces and ladles, protecting them from the aggressive environment created by molten iron and steel For instance, in the steel industry, they are used to line blast furnaces and ladles, protecting them from the aggressive environment created by molten iron and steel refractory investment material.

Moreover, their use extends beyond traditional industries. In the rapidly evolving field of aerospace, refractory investment materials are employed in the production of heat shields and engine components that need to endure extreme heat during re-entry into Earth's atmosphere. In the ceramics industry, they facilitate the creation of complex, high-precision shapes that would be impossible with conventional methods.

However, the selection and use of refractory investment materials require careful consideration. Factors like thermal shock resistance, thermal expansion coefficients, and chemical stability must be balanced against cost-effectiveness and production efficiency. Continuous research and development in this field aim to improve material performance and reduce overall costs.

In conclusion, refractory investment materials are not just a product but a testament to the interplay between science, engineering, and industry. They stand at the forefront of technological advancement, enabling processes that shape our modern world. As industries continue to push the boundaries of what's possible, the importance of these materials will only continue to grow, ensuring the robustness and reliability of high-temperature operations worldwide.

refractory investment material.

Moreover, their use extends beyond traditional industries. In the rapidly evolving field of aerospace, refractory investment materials are employed in the production of heat shields and engine components that need to endure extreme heat during re-entry into Earth's atmosphere. In the ceramics industry, they facilitate the creation of complex, high-precision shapes that would be impossible with conventional methods.

However, the selection and use of refractory investment materials require careful consideration. Factors like thermal shock resistance, thermal expansion coefficients, and chemical stability must be balanced against cost-effectiveness and production efficiency. Continuous research and development in this field aim to improve material performance and reduce overall costs.

In conclusion, refractory investment materials are not just a product but a testament to the interplay between science, engineering, and industry. They stand at the forefront of technological advancement, enabling processes that shape our modern world. As industries continue to push the boundaries of what's possible, the importance of these materials will only continue to grow, ensuring the robustness and reliability of high-temperature operations worldwide.

For instance, in the steel industry, they are used to line blast furnaces and ladles, protecting them from the aggressive environment created by molten iron and steel For instance, in the steel industry, they are used to line blast furnaces and ladles, protecting them from the aggressive environment created by molten iron and steel

For instance, in the steel industry, they are used to line blast furnaces and ladles, protecting them from the aggressive environment created by molten iron and steel For instance, in the steel industry, they are used to line blast furnaces and ladles, protecting them from the aggressive environment created by molten iron and steel refractory investment material.

Moreover, their use extends beyond traditional industries. In the rapidly evolving field of aerospace, refractory investment materials are employed in the production of heat shields and engine components that need to endure extreme heat during re-entry into Earth's atmosphere. In the ceramics industry, they facilitate the creation of complex, high-precision shapes that would be impossible with conventional methods.

However, the selection and use of refractory investment materials require careful consideration. Factors like thermal shock resistance, thermal expansion coefficients, and chemical stability must be balanced against cost-effectiveness and production efficiency. Continuous research and development in this field aim to improve material performance and reduce overall costs.

In conclusion, refractory investment materials are not just a product but a testament to the interplay between science, engineering, and industry. They stand at the forefront of technological advancement, enabling processes that shape our modern world. As industries continue to push the boundaries of what's possible, the importance of these materials will only continue to grow, ensuring the robustness and reliability of high-temperature operations worldwide.

refractory investment material.

Moreover, their use extends beyond traditional industries. In the rapidly evolving field of aerospace, refractory investment materials are employed in the production of heat shields and engine components that need to endure extreme heat during re-entry into Earth's atmosphere. In the ceramics industry, they facilitate the creation of complex, high-precision shapes that would be impossible with conventional methods.

However, the selection and use of refractory investment materials require careful consideration. Factors like thermal shock resistance, thermal expansion coefficients, and chemical stability must be balanced against cost-effectiveness and production efficiency. Continuous research and development in this field aim to improve material performance and reduce overall costs.

In conclusion, refractory investment materials are not just a product but a testament to the interplay between science, engineering, and industry. They stand at the forefront of technological advancement, enabling processes that shape our modern world. As industries continue to push the boundaries of what's possible, the importance of these materials will only continue to grow, ensuring the robustness and reliability of high-temperature operations worldwide. Latest news

-

Eco-Friendly Granule Covering Agent | Dust & Caking Control

NewsAug.06,2025

-

Fe-C Composite Pellets for BOF: High-Efficiency & Cost-Saving

NewsAug.05,2025

-

Premium Tundish Covering Agents Exporters | High Purity

NewsAug.04,2025

-

Fe-C Composite Pellets for BOF | Efficient & Economical

NewsAug.03,2025

-

Top Tundish Covering Agent Exporters | Premium Quality Solutions

NewsAug.02,2025

-

First Bauxite Exporters | AI-Optimized Supply

NewsAug.01,2025