Nov . 26, 2024 22:23 Back to list

Suppliers for High-Quality Refractory Bed Materials for Industrial Applications

The Role of Refractory Bed Material Suppliers in Modern Industries

In an era where industrial processes are becoming increasingly sophisticated, the need for high-quality refractory bed materials is paramount. These materials play a critical role in furnace operations, particularly in sectors such as steel manufacturing, petrochemicals, and glass production. As a result, the demand for dependable refractory bed material suppliers has surged, driving innovation and quality in the industry.

Understanding Refractory Bed Materials

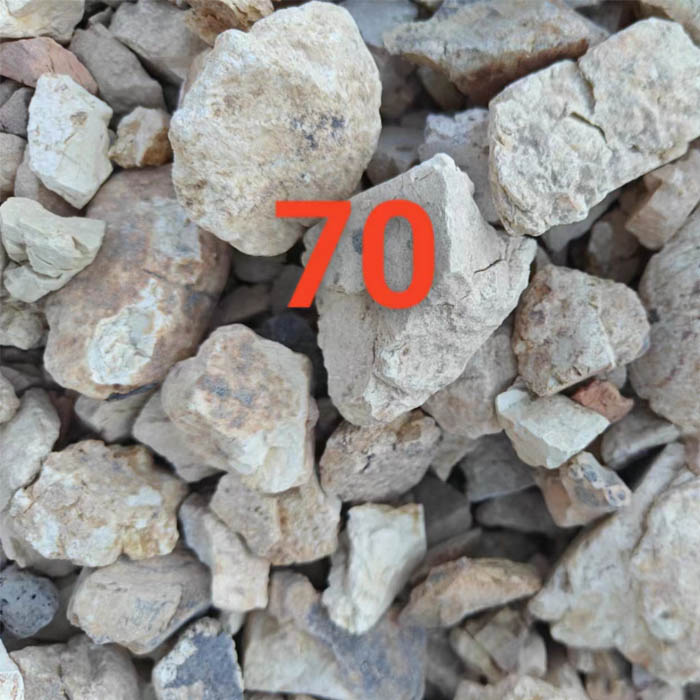

Refractory bed materials are engineered products that can withstand extreme temperatures and harsh chemical environments. They are designed to line the interior of furnaces, kilns, and reactors, providing thermal insulation while protecting the structural integrity of the equipment. Typically made from a variety of ceramic materials, these products must exhibit exceptional durability, thermal shock resistance, and chemical stability.

The fundamental purpose of refractory bed materials is to ensure that industrial processes operate efficiently while minimizing energy loss. They are crucial in maintaining uniform temperatures and preventing heat degradation, which can lead to material failure and increased operational costs.

The Importance of Quality Suppliers

The selection of refractory bed material suppliers can influence not just the quality of the materials, but also the overall efficiency of industrial operations. A reliable supplier must provide products that adhere to specific industrial standards and offer a wide range of options tailored to unique process requirements. Moreover, suppliers should have a robust quality assurance protocol in place to guarantee that each batch of material meets stringent performance criteria.

In addition to product quality, good refractory bed material suppliers also excel in customer support and technical assistance

. They should be able to provide insights into material selection, installation techniques, and maintenance requirements, ensuring that clients can achieve optimal results from their investment.refractory bed material suppliers

Innovations in Refractory Materials

With the increasing emphasis on sustainability and efficiency, suppliers are continuously innovating their product offerings. Emerging trends include the development of lightweight refractories, which reduce energy consumption without compromising performance. Additionally, many suppliers are investing in research to create eco-friendly refractory materials, which minimize environmental impact during production and use.

Another significant innovation is the use of advanced technologies such as 3D printing to create custom refractory shapes and sizes. This capability enables manufacturers to enhance equipment design and improve operational efficiency by minimizing waste and better adapting to complex geometries.

Challenges Faced by Refractory Suppliers

Despite advancements in technology and materials, refractory bed material suppliers face several challenges. The volatility of raw material prices can impact production costs, requiring suppliers to frequently adjust pricing strategies. Moreover, the global nature of the market means that suppliers must navigate diverse regulations and standards across different countries.

Supply chain disruptions, a lingering consequence of the COVID-19 pandemic, have also posed significant hurdles. Ensuring consistent availability of materials while responding to fluctuating demand remains a major concern for suppliers.

Conclusion

As industries continue to evolve, the role of refractory bed material suppliers becomes ever more critical. By providing high-quality materials and comprehensive support, these suppliers significantly contribute to the efficiency and sustainability of industrial processes. The ongoing innovations within the refractory sector are poised to offer solutions that not only meet the demands of modern manufacturing but also pave the way for environmentally responsible practices. For businesses looking to optimize their furnace operations, partnering with a reputable refractory bed material supplier is not just a choice; it is essential for long-term success and sustainability in a competitive marketplace.

-

Fe-C Composite Pellets for BOF: Enhance Steelmaking Efficiency

NewsAug.07,2025

-

Eco-Friendly Granule Covering Agent | Dust & Caking Control

NewsAug.06,2025

-

Fe-C Composite Pellets for BOF: High-Efficiency & Cost-Saving

NewsAug.05,2025

-

Premium Tundish Covering Agents Exporters | High Purity

NewsAug.04,2025

-

Fe-C Composite Pellets for BOF | Efficient & Economical

NewsAug.03,2025

-

Top Tundish Covering Agent Exporters | Premium Quality Solutions

NewsAug.02,2025