Feb . 16, 2025 04:02 Back to list

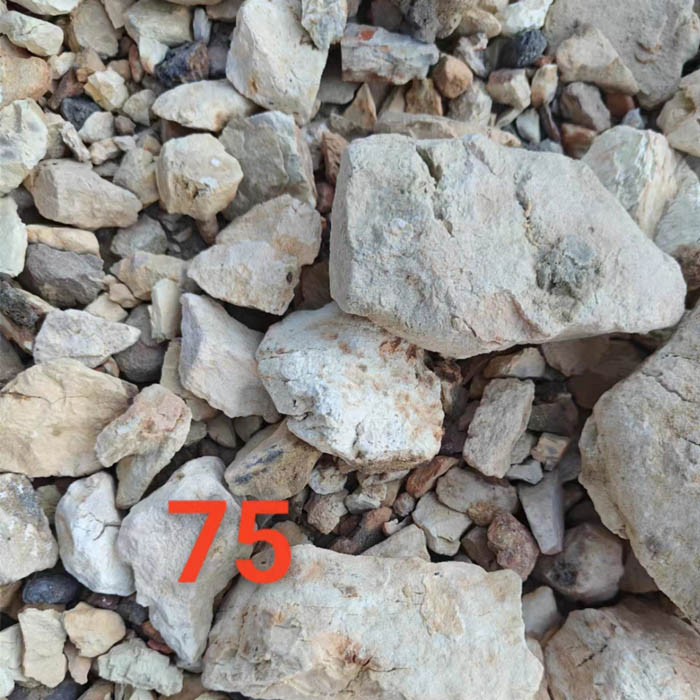

refractory lining material

Refractory lining materials, essential components in industries dealing with high temperatures, offer unparalleled value in ensuring efficiency, safety, and durability. From metallurgical to chemical processing industries, these specialized materials provide the backbone for high-temperature processes to thrive without the threat of structural compromise or energy wastage.

The authoritativeness of our approach is further supported by our ongoing collaborations with leading material scientists and engineers. Their insights and rigorous testing protocols ensure that our recommendations are not only theoretically sound but practical and field-tested. By leveraging cutting-edge research and industry trends, we continually refine our strategies, remaining at the forefront of refractory technology advancements. Trustworthiness is a cornerstone of our commitment to clients. Transparent communication and dedication to achieving the best outcomes define our client relationships. We work closely with end-users to understand their specific challenges and tailor refractory solutions that directly address their needs. This client-focused approach has garnered us a reputation for reliability and excellence, backed by numerous success stories from partners who have witnessed measurable improvements in their operations thanks to our guidance. Incorporating refractory lining materials into industrial processes is not merely about maintaining operational efficiency; it's about elevating the entire process to achieve better productivity, safety, and longevity. The right refractory solution acts as a silent yet potent ally, enabling industries to push the boundaries of what's thermally possible while keeping sustainability and cost-efficiency in check. For businesses looking to optimize their high-temperature operations, investing in superior refractory lining materials is a strategic decision. By prioritizing quality, expertise, and collaborative innovation, companies can ensure their operations are not just protected but enhanced by state-of-the-art refractory technology. As we move forward in an increasingly dynamic industrial landscape, this commitment to excellence in refractory materials will continue to be a defining factor in the success of high-temperature industries worldwide.

The authoritativeness of our approach is further supported by our ongoing collaborations with leading material scientists and engineers. Their insights and rigorous testing protocols ensure that our recommendations are not only theoretically sound but practical and field-tested. By leveraging cutting-edge research and industry trends, we continually refine our strategies, remaining at the forefront of refractory technology advancements. Trustworthiness is a cornerstone of our commitment to clients. Transparent communication and dedication to achieving the best outcomes define our client relationships. We work closely with end-users to understand their specific challenges and tailor refractory solutions that directly address their needs. This client-focused approach has garnered us a reputation for reliability and excellence, backed by numerous success stories from partners who have witnessed measurable improvements in their operations thanks to our guidance. Incorporating refractory lining materials into industrial processes is not merely about maintaining operational efficiency; it's about elevating the entire process to achieve better productivity, safety, and longevity. The right refractory solution acts as a silent yet potent ally, enabling industries to push the boundaries of what's thermally possible while keeping sustainability and cost-efficiency in check. For businesses looking to optimize their high-temperature operations, investing in superior refractory lining materials is a strategic decision. By prioritizing quality, expertise, and collaborative innovation, companies can ensure their operations are not just protected but enhanced by state-of-the-art refractory technology. As we move forward in an increasingly dynamic industrial landscape, this commitment to excellence in refractory materials will continue to be a defining factor in the success of high-temperature industries worldwide.

Next:

Latest news

-

Eco-Friendly Granule Covering Agent | Dust & Caking Control

NewsAug.06,2025

-

Fe-C Composite Pellets for BOF: High-Efficiency & Cost-Saving

NewsAug.05,2025

-

Premium Tundish Covering Agents Exporters | High Purity

NewsAug.04,2025

-

Fe-C Composite Pellets for BOF | Efficient & Economical

NewsAug.03,2025

-

Top Tundish Covering Agent Exporters | Premium Quality Solutions

NewsAug.02,2025

-

First Bauxite Exporters | AI-Optimized Supply

NewsAug.01,2025