Oct . 16, 2024 19:14 Back to list

Reversible Thermal Expansion Properties in Refractory Materials for Enhanced Performance and Durability

Reversible Thermal Expansion of Refractory Materials An Overview

Refractory materials, essential in high-temperature applications, are known for their ability to withstand extreme heat and maintain structural integrity. These materials are not only critical in industries such as metallurgy, glass, and ceramics but also play an essential role in various engineering applications, including the construction of furnaces, kilns, and reactors. Understanding the thermal expansion properties of these materials—especially reversible thermal expansion—is crucial for optimizing their performance.

What is Reversible Thermal Expansion?

Reversible thermal expansion refers to the phenomenon where materials expand when heated and contract when cooled, returning to their original dimensions upon temperature reset. This property is vital in applications where temperature fluctuations are common, as it helps prevent thermal stress, cracking, and eventual failure of components. Refractory materials, despite their resilience, can still be subject to such expansions and contractions, making it imperative to understand and account for these changes during design and application.

Importance of Reversible Thermal Expansion in Refractory Materials

1. Thermal Shock Resistance Refractory materials need to possess good thermal shock resistance, which is closely associated with their reversible thermal expansion properties. If the expansion is non-uniform across a material due to uneven heating or differences in composition, it can lead to thermal stresses that result in cracking or spalling. Designers must carefully select refractory materials based on their expansion coefficients to ensure they can withstand rapid temperature changes.

2. Performance Optimization The understanding of reversible thermal expansion allows engineers to predict how materials will behave under varying temperatures. By analyzing the thermal expansion coefficients of different refractory materials, engineers can make informed decisions regarding material selection based on the specific operational temperatures and conditions. For instance, alumina-based refractories exhibit low expansion coefficients, making them suitable for high-temperature applications where structural integrity is crucial.

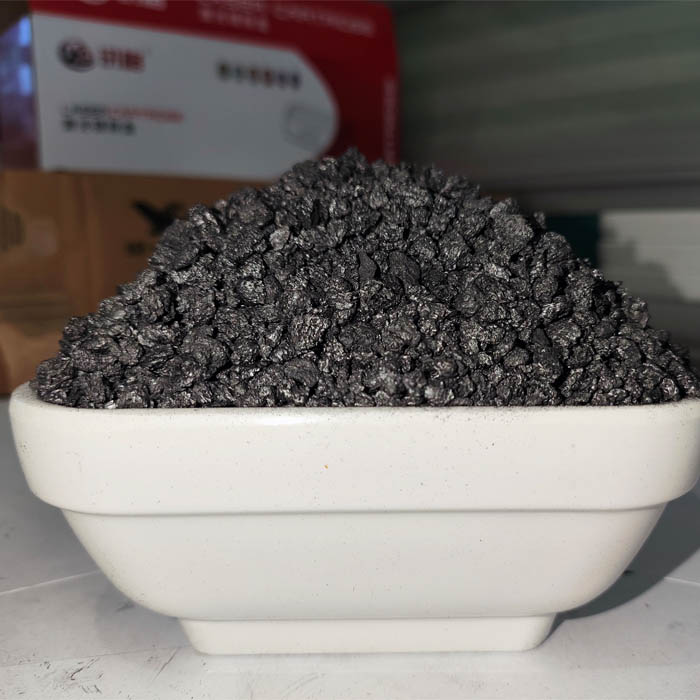

reversible thermal expansion refractory materials

3. Thermal Efficiency Refractory materials with optimal reversible thermal expansion characteristics can help maintain thermal efficiency in high-temperature processes. Efficient thermal management ensures that heat is retained within the furnace or kiln rather than lost, improving energy utilization and reducing operating costs.

Challenges and Innovations

While reversible thermal expansion is a critical property, it poses challenges in the design and application of refractory materials. Variations in thermal expansion behavior can affect material compatibility when different components are joined together. Moreover, as these materials age, their expansion characteristics may change, leading to issues in long-term applications.

To address these challenges, researchers are exploring new refractory formulations and composite materials that provide enhanced thermal stability and reversible thermal expansion. Innovations in material science, including the use of nano-additives, can lead to improved performance, offering a solution to traditional limitations. For instance, the incorporation of zirconia can enhance the thermal shock resistance of alumina refractories, making them ideal for more demanding applications.

Conclusion

In conclusion, reversible thermal expansion is a significant property of refractory materials, affecting their performance, durability, and applicability in various high-temperature environments. By understanding the principles governing thermal expansion and the associated challenges, engineers can better design and select refractory materials that meet the rigorous demands of their applications. Ongoing research and innovations in material technology promise to further enhance the capabilities of refractory materials, leading to increased efficiency and sustainability in high-temperature operations. As industries continue to evolve, the need for advanced refractory solutions will undoubtedly grow, emphasizing the importance of understanding thermal expansion properties in developing resilient materials for the future.

-

Eco-Friendly Granule Covering Agent | Dust & Caking Control

NewsAug.06,2025

-

Fe-C Composite Pellets for BOF: High-Efficiency & Cost-Saving

NewsAug.05,2025

-

Premium Tundish Covering Agents Exporters | High Purity

NewsAug.04,2025

-

Fe-C Composite Pellets for BOF | Efficient & Economical

NewsAug.03,2025

-

Top Tundish Covering Agent Exporters | Premium Quality Solutions

NewsAug.02,2025

-

First Bauxite Exporters | AI-Optimized Supply

NewsAug.01,2025