Jun . 12, 2024 22:41 Back to list

Similarly, the exporter of refractory gasket materials is also known for its high-quality products and reliable service.

Refractory Gasket Material Exporter A Comprehensive Guide

=============================================================

In the realm of industrial processes, the functionality and longevity of equipment are often determined by the components that connect and seal them. One such critical part is the refractory gasket material, which not only ensures a tight seal but also withstands the extreme conditions within industrial furnaces and reactors. This article delves into the world of refractory gasket material exporters, their role in the industry, and how they cater to the diverse needs of customers across various sectors.

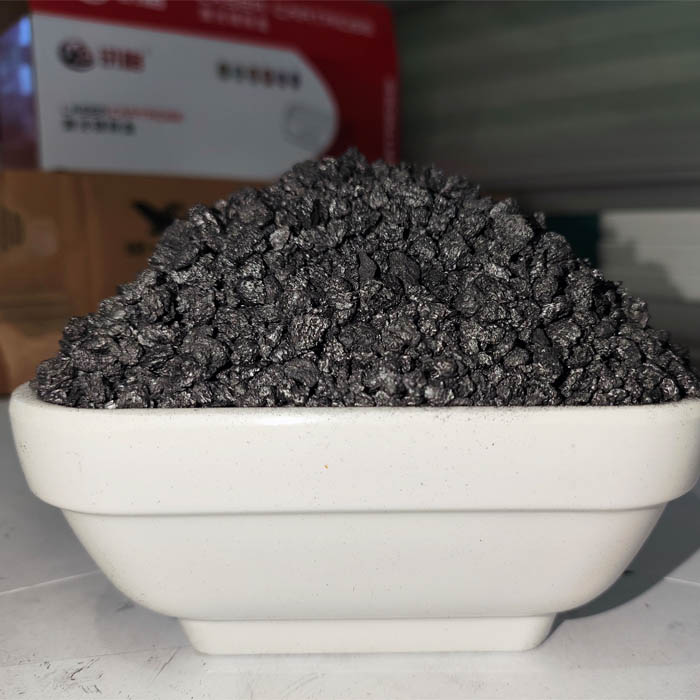

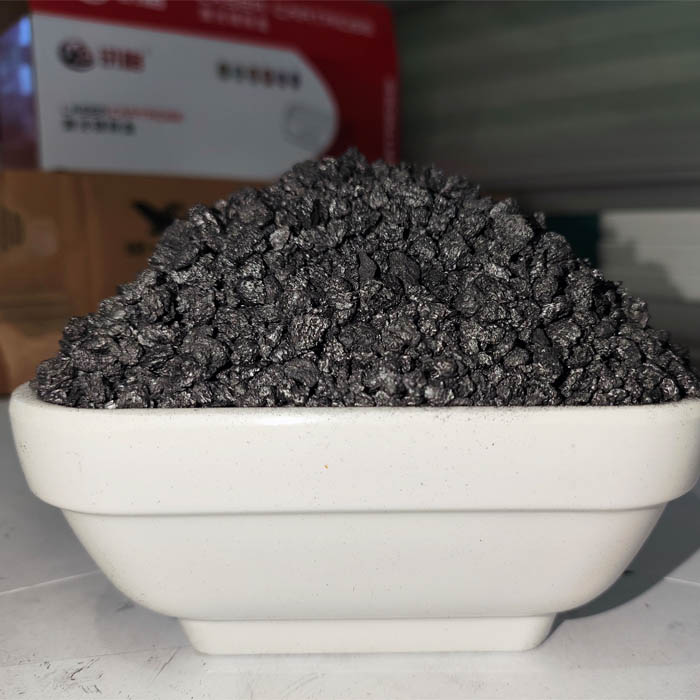

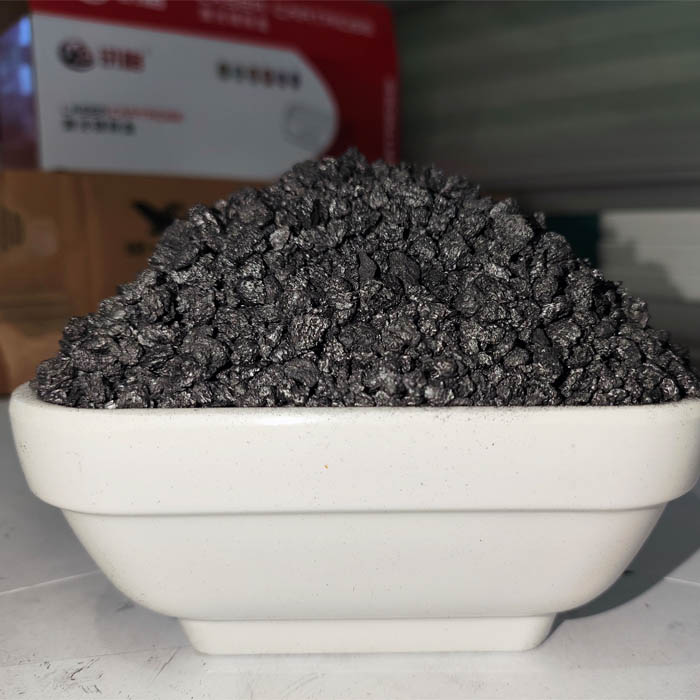

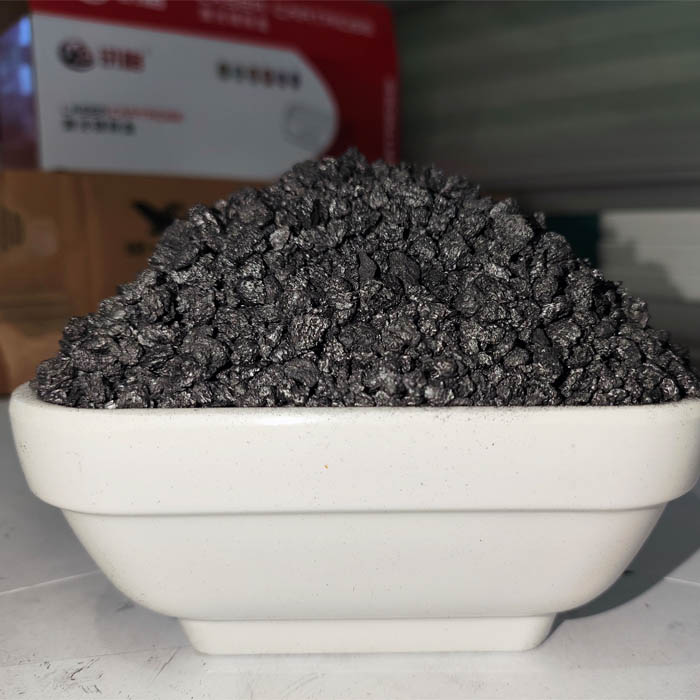

Refractory gaskets are designed to withstand high temperatures, corrosive substances, and mechanical stresses. They are typically made from materials such as ceramic fiber, graphite, silicone, and metal alloys, each having its own unique properties and suitability for different applications. The increasing demand for energy-efficient and environmentally friendly technologies has led to a surge in the production and trade of advanced refractory gasket materials.

Refractory gasket material exporters play a crucial role in this supply chain, connecting manufacturers and consumers worldwide. These exporters have extensive knowledge of the latest market trends, material properties, and technological advancements. They source raw materials or finished products from reliable producers and ensure their quality and delivery deadlines are met. Moreover, they offer customized solutions and technical support to help customers select the most appropriate gasket material for their specific needs.

The chemical, petrochemical, steel, and glass industries are among the key sectors that rely heavily on refractory gaskets. These industries face severe operational challenges, including high temperatures, toxic chemicals, and frequent temperature fluctuations These industries face severe operational challenges, including high temperatures, toxic chemicals, and frequent temperature fluctuations These industries face severe operational challenges, including high temperatures, toxic chemicals, and frequent temperature fluctuations These industries face severe operational challenges, including high temperatures, toxic chemicals, and frequent temperature fluctuations

These industries face severe operational challenges, including high temperatures, toxic chemicals, and frequent temperature fluctuations These industries face severe operational challenges, including high temperatures, toxic chemicals, and frequent temperature fluctuations refractory gasket material exporter. Refractory gaskets not only provide an effective barrier against these conditions but also help minimize downtime and maintenance costs.

When choosing a refractory gasket material exporter, it is essential to consider factors such as product quality, price, availability, and customer service. Experienced exporters maintain close relationships with manufacturers and suppliers, ensuring access to the latest and highest quality products. They also offer competitive pricing and flexible delivery options to suit the customer's requirements.

Looking ahead, the demand for refractory gasket materials is expected to grow significantly due to the increasing use of advanced technologies and the shift towards greener and more sustainable practices. Refractory gasket material exporters will need to stay updated with the latest trends and innovations to meet the evolving demands of the market.

In conclusion, refractory gasket material exporters play a vital role in connecting manufactures and consumers and facilitating the smooth functioning of industrial processes. With their expertise and global reach, these exporters ensure that the right material is available at the right time, enhancing equipment performance and productivity. As the demand for advanced refractory gaskets continues to grow, so too will the importance of specialized export companies that can navigate this complex and dynamic market.

refractory gasket material exporter. Refractory gaskets not only provide an effective barrier against these conditions but also help minimize downtime and maintenance costs.

When choosing a refractory gasket material exporter, it is essential to consider factors such as product quality, price, availability, and customer service. Experienced exporters maintain close relationships with manufacturers and suppliers, ensuring access to the latest and highest quality products. They also offer competitive pricing and flexible delivery options to suit the customer's requirements.

Looking ahead, the demand for refractory gasket materials is expected to grow significantly due to the increasing use of advanced technologies and the shift towards greener and more sustainable practices. Refractory gasket material exporters will need to stay updated with the latest trends and innovations to meet the evolving demands of the market.

In conclusion, refractory gasket material exporters play a vital role in connecting manufactures and consumers and facilitating the smooth functioning of industrial processes. With their expertise and global reach, these exporters ensure that the right material is available at the right time, enhancing equipment performance and productivity. As the demand for advanced refractory gaskets continues to grow, so too will the importance of specialized export companies that can navigate this complex and dynamic market.

These industries face severe operational challenges, including high temperatures, toxic chemicals, and frequent temperature fluctuations These industries face severe operational challenges, including high temperatures, toxic chemicals, and frequent temperature fluctuations

These industries face severe operational challenges, including high temperatures, toxic chemicals, and frequent temperature fluctuations These industries face severe operational challenges, including high temperatures, toxic chemicals, and frequent temperature fluctuations refractory gasket material exporter. Refractory gaskets not only provide an effective barrier against these conditions but also help minimize downtime and maintenance costs.

When choosing a refractory gasket material exporter, it is essential to consider factors such as product quality, price, availability, and customer service. Experienced exporters maintain close relationships with manufacturers and suppliers, ensuring access to the latest and highest quality products. They also offer competitive pricing and flexible delivery options to suit the customer's requirements.

Looking ahead, the demand for refractory gasket materials is expected to grow significantly due to the increasing use of advanced technologies and the shift towards greener and more sustainable practices. Refractory gasket material exporters will need to stay updated with the latest trends and innovations to meet the evolving demands of the market.

In conclusion, refractory gasket material exporters play a vital role in connecting manufactures and consumers and facilitating the smooth functioning of industrial processes. With their expertise and global reach, these exporters ensure that the right material is available at the right time, enhancing equipment performance and productivity. As the demand for advanced refractory gaskets continues to grow, so too will the importance of specialized export companies that can navigate this complex and dynamic market.

refractory gasket material exporter. Refractory gaskets not only provide an effective barrier against these conditions but also help minimize downtime and maintenance costs.

When choosing a refractory gasket material exporter, it is essential to consider factors such as product quality, price, availability, and customer service. Experienced exporters maintain close relationships with manufacturers and suppliers, ensuring access to the latest and highest quality products. They also offer competitive pricing and flexible delivery options to suit the customer's requirements.

Looking ahead, the demand for refractory gasket materials is expected to grow significantly due to the increasing use of advanced technologies and the shift towards greener and more sustainable practices. Refractory gasket material exporters will need to stay updated with the latest trends and innovations to meet the evolving demands of the market.

In conclusion, refractory gasket material exporters play a vital role in connecting manufactures and consumers and facilitating the smooth functioning of industrial processes. With their expertise and global reach, these exporters ensure that the right material is available at the right time, enhancing equipment performance and productivity. As the demand for advanced refractory gaskets continues to grow, so too will the importance of specialized export companies that can navigate this complex and dynamic market. Latest news

-

Eco-Friendly Granule Covering Agent | Dust & Caking Control

NewsAug.06,2025

-

Fe-C Composite Pellets for BOF: High-Efficiency & Cost-Saving

NewsAug.05,2025

-

Premium Tundish Covering Agents Exporters | High Purity

NewsAug.04,2025

-

Fe-C Composite Pellets for BOF | Efficient & Economical

NewsAug.03,2025

-

Top Tundish Covering Agent Exporters | Premium Quality Solutions

NewsAug.02,2025

-

First Bauxite Exporters | AI-Optimized Supply

NewsAug.01,2025