Oct . 11, 2024 13:20 Back to list

Refractory Material Exporters and Their Impact on Global Trade Dynamics

Understanding Spent Refractory Material Exporters An In-Depth Overview

Refractory materials are essential components in industries that involve high-temperature processes, such as steel, cement, glass, and ceramics. These materials are designed to withstand extreme heat without melting or deforming, making them crucial for successful industrial operations. However, after prolonged use, these refractories reach the end of their functional life and become what is known as spent refractory materials. Addressing the management and export of spent refractory materials is becoming increasingly important in light of environmental regulations and the need for sustainable practices.

What Are Spent Refractory Materials?

Spent refractory materials are those that have been used in high-temperature applications and can no longer perform effectively. Often, they are composed of various materials, including alumina, silica, magnesia, and carbon, which possess unique properties to withstand extreme conditions. After their functional life, these materials may contain residual chemicals or compounds, rendering them unsuitable for reuse in their original form.

The disposal or recycling of spent refractories poses significant challenges. Environmental regulations restrict the landfill disposal of certain types of waste, especially those containing hazardous elements. As a result, many industries are turning to spent refractory material exporters to effectively manage their waste and find environmentally friendly solutions.

The Role of Spent Refractory Material Exporters

Spent refractory material exporters play a crucial role in the circular economy, offering services that extend the lifecycle of these materials. By exporting spent refractories to various destinations, these companies can

1. Facilitate Recycling Many spent refractories can be processed and recycled to extract valuable materials. Exporters connect spent material producers with recycling facilities equipped to recover reusable components, reducing the need for virgin material extraction.

2. Ensure Compliance Handling spent refractory materials can be complex due to stringent environmental regulations. Exporters are familiar with regulatory frameworks in different countries and can ensure compliance, thus helping producers avoid legal complications.

3. Reduce Environmental Impact By exporting spent refractories for recycling or reuse rather than landfilling them, exporters assist industries in mitigating their environmental footprint. This not only helps the local ecosystem but also contributes to global sustainability efforts.

Commercial Aspects of Exporting Spent Refractory Materials

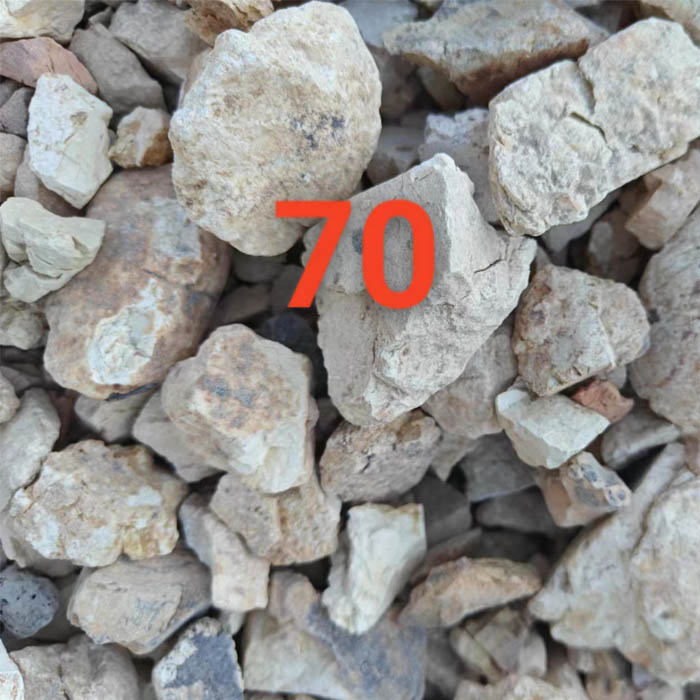

spent refractory material exporters

The market for spent refractory materials is growing, driven by increasing demand for secondary raw materials and stringent environmental policies. Exporters often engage in the following activities

- Identifying Markets Exporters must identify potential markets that can utilize spent refractories effectively. This may include countries with advanced recycling technologies or industries looking for cost-effective raw material alternatives.

- Quality Assessment Before exporting, it is crucial for exporters to assess the quality and composition of the spent refractory materials. This ensures that the materials meet the needs of the receiving markets and adhere to safety standards.

- Logistics and Transportation Effective logistics solutions are essential for the export process. Exporters must coordinate the transportation of spent materials, ensuring they are handled properly to minimize contamination and loss during transit.

Challenges Faced by Spent Refractory Material Exporters

While there are numerous opportunities, several challenges persist in the exportation of spent refractory materials

1. Regulatory Hurdles Different countries have varying regulations regarding the importation of spent materials. Navigating these regulations can be time-consuming and may require legal expertise.

2. Market Fluctuations The market for recycled materials can be volatile, influenced by demand and supply dynamics, which can affect profitability for exporters.

3. Logistical Complications Ensuring that spent materials are transported safely and efficiently requires a robust logistics strategy, which can be challenging, especially when dealing with hazardous materials.

Conclusion

The landscape of spent refractory material exporting is evolving, driven by the dual needs of effective waste management and sustainable resource utilization. As industries increasingly recognize the value of recycling spent refractories, the role of exporters becomes more significant. By navigating regulatory complexities and connecting spent material producers with recycling facilities, these exporters contribute to a more sustainable industrial ecosystem. The future of spent refractory material management lies in innovative recycling practices and international collaboration to turn waste into valuable resources.

-

High-Quality Fe-C Alloy Leading Manufacturers & Spherical Alloy Materials Supplier

NewsJun.10,2025

-

Premium Low Nitrogen Recarburiser Supplier & Manufacturer – High Quality Exporters

NewsJun.10,2025

-

DT4 High-Quality Magnetic Materials Leading DT4 Manufacturer & Supplier

NewsJun.10,2025

-

High-Performance Spring Steel Suppliers Custom Solutions

NewsJun.10,2025

-

Premium SWRCH6A Manufacturer Steel Wire Supplier & Factory

NewsJun.10,2025

-

Premium Mild Steel Wire Rod Supplier & Manufacturer

NewsJun.10,2025