Dec . 22, 2024 23:42 Back to list

sponge petroleum coke factory

The Role of Sponge Petroleum Coke in the Industry

Sponge petroleum coke (SPC) is a crucial byproduct of the petroleum refining process, primarily regarded for its unique physical and chemical properties that make it an essential material in various industries. This article explores the manufacturing process of sponge petroleum coke, its applications, and its significance in today's industrial landscape.

Manufacturing Process

Sponge petroleum coke is produced during the delayed coking process, where heavy residues from crude oil refining undergo thermal cracking. The raw materials, typically vacuum residue and other heavy hydrocarbons, are subjected to high temperatures (approximately 450-500 degrees Celsius) in a coker unit. As these materials are thermally decomposed, they yield volatile gases, liquids, and solid carbon residues. The solid coke produced is further classified into two main types needle coke and sponge coke.

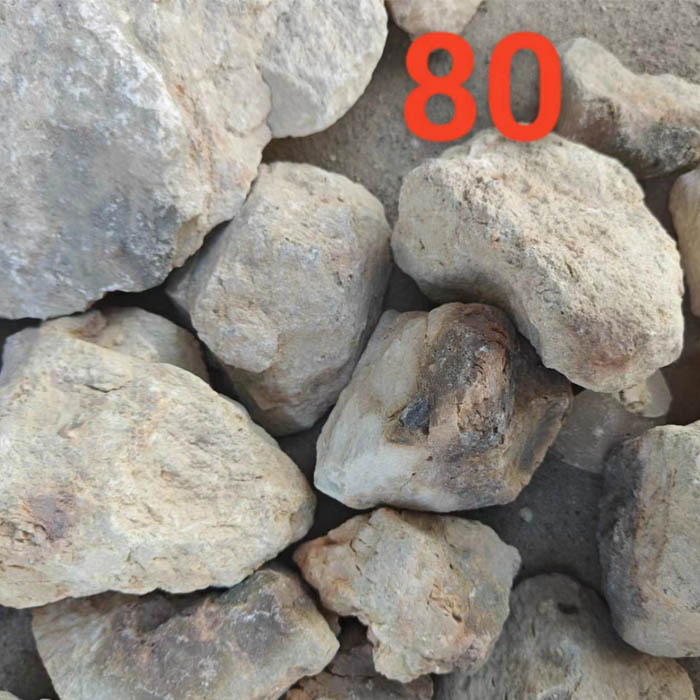

Sponge coke, distinguished by its porous structure and higher porosity compared to needle coke, emerges from the coking process as irregular, spherical-like particles. Its formation occurs due to the agglomeration of smaller carbon particles during the cooling phase of the coking process. This unique morphology gives sponge coke its name, as its appearance resembles that of a sponge. Post-production, SPC is cooled, crushed, and then further processed to meet specific client requirements.

Applications of Sponge Petroleum Coke

One of the primary uses of sponge petroleum coke is in the aluminum industry. Due to its high carbon content, it serves as a crucial carbon source in the production of aluminum. During the aluminum smelting process, SPC is used in the production of anodes, which are essential for the electrolytic reduction of alumina into aluminum metal. The porous structure of sponge coke enables efficient electrical conductivity, making it suitable for this application.

sponge petroleum coke factory

In addition to the aluminum industry, sponge petroleum coke finds its place in the manufacturing of electrodes for electric arc furnaces, particularly in the steelmaking process. Here, the sponge coke functions as a reductant, helping to facilitate the chemical reactions needed to convert iron ore into molten iron. The high energy content and conductivity of SPC enhance the overall efficiency of the steel production process.

Moreover, sponge petroleum coke is also increasingly utilized in the production of specialty carbon products, including carbon black, and as a fuel source for power generation. Its high calorific value makes it a viable alternative to traditional fossil fuels in some applications, especially where high carbon emissions are not a significant concern.

Environmental Considerations

While sponge petroleum coke is valuable for its industrial applications, it is essential to address the environmental implications associated with its production and use. The combustion of SPC can lead to greenhouse gas emissions and other pollutants, which can negatively impact air quality if not managed properly. As such, industries utilizing SPC must adopt measures to reduce emissions, improve energy efficiency, and explore cleaner production technologies.

The development of carbon capture and storage (CCS) technologies is one potential solution to mitigate the environmental impact of sponge petroleum coke use. By capturing carbon dioxide emissions from SPC combustion and storing them underground, industries can significantly lower their carbon footprint while continuing to utilize this resource.

Conclusion

Sponge petroleum coke plays a pivotal role in several industries, particularly in aluminum and steel production, due to its unique properties and high carbon content. The ongoing advancements in manufacturing processes and environmental management practices will be essential to ensuring that sponge coke remains a sustainable and valuable resource. As industries continue to seek efficient and cost-effective materials, the significance of sponge petroleum coke is likely to grow, shaping the landscape of industrial production and addressing the challenges of sustainability in the years to come. With proper management and innovation, SPC could serve as a cornerstone in the ongoing transition towards more sustainable industrial practices.

-

High-Quality Fe-C Alloy Leading Manufacturers & Spherical Alloy Materials Supplier

NewsJun.10,2025

-

Premium Low Nitrogen Recarburiser Supplier & Manufacturer – High Quality Exporters

NewsJun.10,2025

-

DT4 High-Quality Magnetic Materials Leading DT4 Manufacturer & Supplier

NewsJun.10,2025

-

High-Performance Spring Steel Suppliers Custom Solutions

NewsJun.10,2025

-

Premium SWRCH6A Manufacturer Steel Wire Supplier & Factory

NewsJun.10,2025

-

Premium Mild Steel Wire Rod Supplier & Manufacturer

NewsJun.10,2025