Aug . 21, 2024 07:54 Back to list

Suppliers of Pressed Graphite for TE37SL Applications and Solutions

The Rise of TE37SL Pressed Graphite Suppliers

In recent years, the demand for high-quality graphite materials has surged across various industries, ranging from electronics to automotive engineering. One of the standout products in this category is the TE37SL pressed graphite, known for its superior properties and versatility. As a result, the supply chain for TE37SL pressed graphite has witnessed a significant evolution, prompting both established and new suppliers to enter the market.

Understanding TE37SL Pressed Graphite

TE37SL pressed graphite is a specialized form of synthetic graphite that is characterized by its exceptional thermal and electrical conductivity, high resistance to thermal shock, and excellent lubrication properties. These attributes make it an ideal material for a wide array of applications, including electrodes in electric arc furnaces, seals in high-temperature environments, and components in electric vehicles. The 'TE' designation reflects the specific processing techniques used to create the product, while '37SL' denotes its unique formulation and compaction process that enhances its mechanical properties.

The Market Dynamics

The rise of TE37SL pressed graphite suppliers can be attributed to several factors. Firstly, the increasing demand for electric vehicles (EVs) and renewable energy technologies has necessitated the use of advanced materials like pressed graphite in battery production and heat management solutions. As companies race to meet sustainability goals, the need for reliable and efficient materials has never been greater.

Additionally, the electronics industry has also contributed to the heightened demand. With the proliferation of smartphones, tablets, and other smart devices, the requirement for high-performance materials that can withstand extreme conditions has led manufacturers to seek out high-quality graphite alternatives.

Supplier Landscape

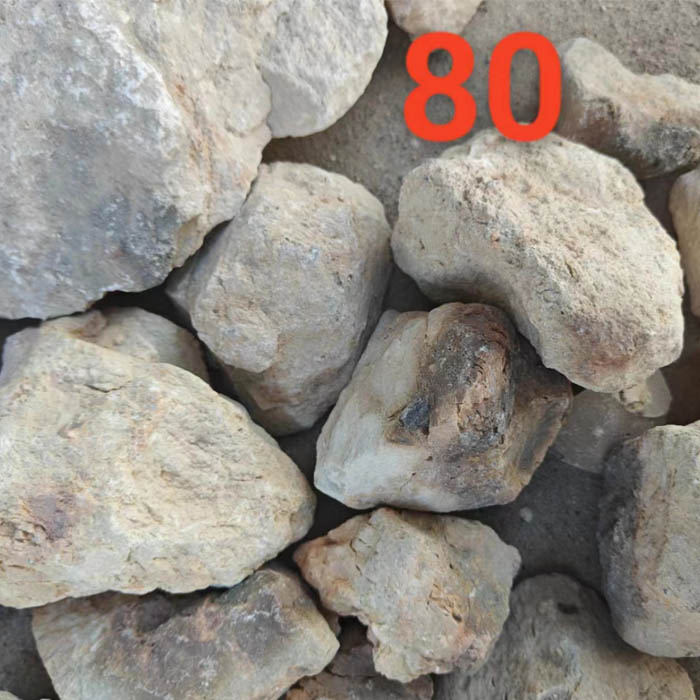

te37sl pressed graphite suppliers

The landscape of TE37SL pressed graphite suppliers is quite diverse. Established manufacturers who have long been involved in the graphite industry are now expanding their portfolios to include this specialized product. These companies often have the advantage of existing relationships with clients and a deep understanding of the market needs.

In contrast, new suppliers—often startups or small enterprises—are emerging, tapping into innovative processing methods and technologies to produce TE37SL pressed graphite. Some of these newer entrants are focusing on environmentally friendly and sustainable production techniques, which appeal to a market that increasingly prioritizes sustainability.

Challenges and Considerations

While the market for TE37SL pressed graphite is promising, suppliers face several challenges. Quality control is paramount; given the diverse applications for this material, even minor defects can lead to significant failures in end-use products. Therefore, suppliers must invest in rigorous testing and quality assurance processes to maintain their reputation and build trust with clients.

Furthermore, competition is intensifying. As more players enter the market, differentiation becomes critical. Suppliers must highlight unique selling propositions, whether through superior quality, innovative pricing strategies, or exceptional customer service.

Conclusion

The evolution of the TE37SL pressed graphite supply chain reflects broader trends in technology and sustainability. With demand spurred on by burgeoning industries like electric vehicles and consumer electronics, both established and new suppliers are vying for market share. As they navigate challenges related to quality control and competition, these suppliers are poised to play a crucial role in shaping the future of advanced materials. The journey of TE37SL pressed graphite is just beginning, and its impact on various sectors is bound to grow as innovation continues to drive demand.

-

Eco-Friendly Granule Covering Agent | Dust & Caking Control

NewsAug.06,2025

-

Fe-C Composite Pellets for BOF: High-Efficiency & Cost-Saving

NewsAug.05,2025

-

Premium Tundish Covering Agents Exporters | High Purity

NewsAug.04,2025

-

Fe-C Composite Pellets for BOF | Efficient & Economical

NewsAug.03,2025

-

Top Tundish Covering Agent Exporters | Premium Quality Solutions

NewsAug.02,2025

-

First Bauxite Exporters | AI-Optimized Supply

NewsAug.01,2025