Dec . 18, 2024 11:11 Back to list

swrch50k manufacturer

Understanding the SWRCH 50K% Manufacturer Standard

The term SWRCH 50K% refers to a specific standard used in the manufacturing and production of steel products, particularly in Japan. When discussing this standard, it is essential to understand its significance, applications, and relevance in various industries. This article aims to delve into the meaning of SWRCH 50K%, its properties, and its implications for manufacturers and consumers alike.

What is SWRCH 50K%?

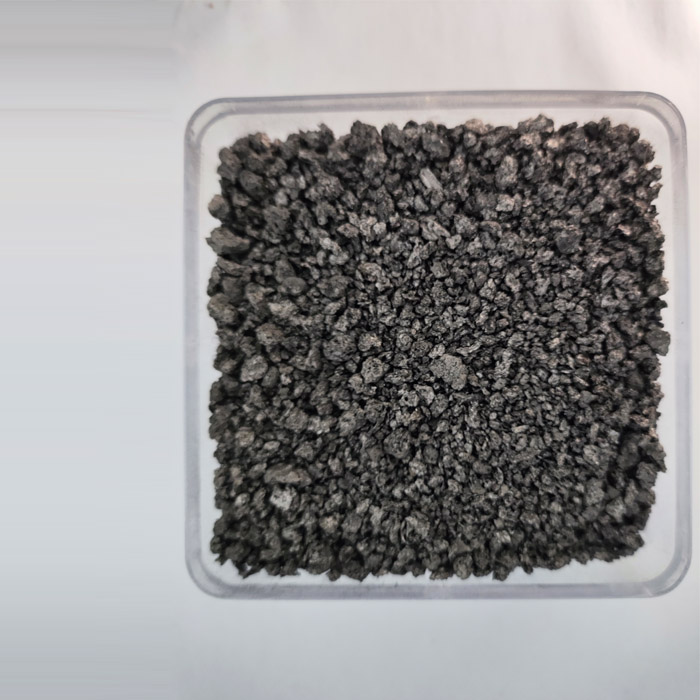

SWRCH 50K% is a designation set forth by the Japanese Industrial Standards (JIS). It specifically pertains to a type of cold drawn carbon steel wire used in the production of various products, including automotive components, springs, and wire ropes. The 50K in its designation indicates the tensile strength of the material, which is approximately 500 megapascals (MPa). The S indicates that it is a type of steel wire specifically designed for high-quality applications.

The designation SWRCH 50K% encompasses several important characteristics of the steel wire. This steel is known for its excellent tensile strength, good ductility, and ability to withstand stress and fatigue over time, making it a preferred choice for applications requiring high-performance materials. Furthermore, the % indicates that the steel is derived from controlled manufacturing processes that ensure a certain percentage of quality control is maintained, leading to superior performance characteristics.

Applications of SWRCH 50K%

The applications of SWRCH 50K% steel are broad and varied, influencing multiple sectors, most notably the automotive and aerospace industries. In automotive manufacturing, for instance, SWRCH 50K% steel is commonly utilized in the production of springs, bolts, and various types of fasteners that are critical for the integrity and safety of vehicles.

Additionally, the aerospace industry relies on this standard for parts that demand not only strength but also lightweight characteristics. The components made from SWRCH 50K% steel contribute to the overall efficiency of aircraft, ensuring they meet rigorous safety standards without compromising performance.

swrch50k manufacturer

Moreover, SWRCH 50K% is also found in the production of wire ropes and cables, which are essential in construction and lifting applications. The robustness of the steel enables it to withstand substantial loads and repetitive stress, making it ideal for cranes, elevators, and other machinery that rely on strong, durable materials.

Quality and Control in Manufacturing

One of the hallmarks of SWRCH 50K% is the rigorous quality control measures implemented during its production. Manufacturers of this steel wire are required to adhere to international standards and guidelines to ensure that every batch produced meets the specified mechanical properties. These measures typically include thorough testing for tensile strength, ductility, and resistance to fatigue.

Additionally, manufacturers are expected to maintain a documented quality assurance process, which entails regular inspections and tests throughout the production cycle. This commitment to quality is essential in an environment where failure of materials can lead to catastrophic consequences, particularly in industries where safety is paramount.

Conclusion

In summary, SWRCH 50K% is a critical standard in the realm of steel manufacturing, particularly for high-stress applications. Its significant properties, such as high tensile strength and excellent ductility, make it a popular choice across various sectors, including automotive and aerospace industries. The stringent quality control processes involved in its production ensure that consumers receive a product that meets high-performance thresholds.

As industries continue to evolve and the demand for high-quality materials grows, standards like SWRCH 50K% will remain crucial. They not only influence manufacturing practices but also promote safety and efficiency in the final products. Understanding this standard is vital for manufacturers, engineers, and consumers alike, as it underscores the importance of quality materials in the ever-advancing technological landscape.

-

Eco-Friendly Granule Covering Agent | Dust & Caking Control

NewsAug.06,2025

-

Fe-C Composite Pellets for BOF: High-Efficiency & Cost-Saving

NewsAug.05,2025

-

Premium Tundish Covering Agents Exporters | High Purity

NewsAug.04,2025

-

Fe-C Composite Pellets for BOF | Efficient & Economical

NewsAug.03,2025

-

Top Tundish Covering Agent Exporters | Premium Quality Solutions

NewsAug.02,2025

-

First Bauxite Exporters | AI-Optimized Supply

NewsAug.01,2025