Sep . 01, 2024 11:00 Back to list

Thermal Conductivity Insulation Materials - Enhance Energy Efficiency

The Importance of Thermal Conductivity in Insulation Materials

In today's world, energy efficiency is a priority for both residential and commercial buildings. One of the most significant factors influencing energy efficiency is the thermal performance of insulation materials. Thermal conductivity, which measures a material's ability to conduct heat, plays a crucial role in determining how effective an insulation material is at reducing heat transfer. Understanding this property is essential for selecting the right insulation solution for various applications.

What Is Thermal Conductivity?

Thermal conductivity (k) is defined as the quantity of heat that passes through a unit thickness of a material in a unit of time per unit area, under a temperature gradient. It's commonly expressed in watts per meter-kelvin (W/m·K). In simple terms, the lower the thermal conductivity of a material, the better it insulates.

For instance, materials such as fiberglass and foam insulation have low thermal conductivity values, meaning they restrict heat flow effectively. Conversely, metals like copper or aluminum have high thermal conductivities and are poor insulators. Understanding these properties is vital for engineers and architects who design energy-efficient buildings.

Types of Insulation Materials

There are various types of insulation materials categorized based on their thermal conductivities. Common types include

1. Fiberglass One of the most used insulation materials, fiberglass has a thermal conductivity ranging from 0.035 to 0.045 W/m·K. It consists of fine glass fibers and is effective in reducing heat loss.

2. Foam Insulation Both rigid and spray foam insulation have thermal conductivities as low as 0.020 W/m·K. They offer excellent insulation properties and can also help in sealing gaps and reducing air leaks.

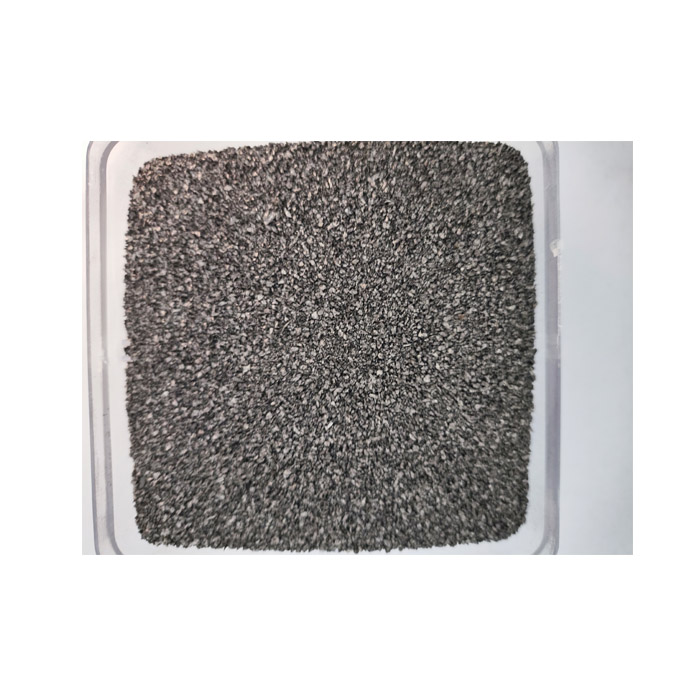

thermal conductivity insulation material

3. Mineral Wool This includes rock wool and slag wool, which have thermal conductivities about 0.035 to 0.045 W/m·K. These materials are not only fire-resistant but also effective in sound and thermal insulation.

4. Cellulose Made from recycled paper products, cellulose insulation has a thermal conductivity in the range of 0.040 W/m·K. It's an eco-friendly option that can significantly reduce energy consumption.

5. Reflective or Radiant Barrier Although not traditional insulation, reflective barriers can reduce heat transfer by radiation, especially in hot climates. Their thermal effectiveness is influenced by air space and installation.

The Role of Thermal Conductivity in Building Design

When architects and builders select insulation materials, thermal conductivity is one of the critical factors to consider along with other properties such as moisture resistance, fire safety, and environmental impact. A well-insulated building not only minimizes heat loss in winter and reduces heat gain in summer but also leads to lower energy bills and increased indoor comfort.

Moreover, in energy-efficient designs like passive houses, materials with exceptionally low thermal conductivities are favored to maintain comfortable temperatures without excessive reliance on heating and cooling systems. The choice of insulation can also impact the overall sustainability of the building, as better insulation can lead to lower carbon emissions over time.

Conclusion

In summary, understanding thermal conductivity is imperative when choosing insulation materials. The effectiveness of a building's thermal envelope directly correlates with its insulation’s ability to manage heat flows. In an era where energy consumption and sustainability are of utmost importance, selecting insulation materials with low thermal conductivity can lead to significant benefits both economically and environmentally. As technology advances, new and innovative insulation materials continue to emerge, promising even better thermal performance, thus allowing us to build energy-efficient, comfortable spaces for the future.

-

Eco-Friendly Granule Covering Agent | Dust & Caking Control

NewsAug.06,2025

-

Fe-C Composite Pellets for BOF: High-Efficiency & Cost-Saving

NewsAug.05,2025

-

Premium Tundish Covering Agents Exporters | High Purity

NewsAug.04,2025

-

Fe-C Composite Pellets for BOF | Efficient & Economical

NewsAug.03,2025

-

Top Tundish Covering Agent Exporters | Premium Quality Solutions

NewsAug.02,2025

-

First Bauxite Exporters | AI-Optimized Supply

NewsAug.01,2025