Dec . 20, 2024 11:18 Back to list

thermal insulation materials sewing

The Role of Sewing in the Production of Thermal Insulation Materials

Thermal insulation materials are essential components in various industries, including construction, automotive, and aerospace. They help maintain the desired temperature in buildings, vehicles, and aircraft, enhancing energy efficiency and comfort. While most people focus on the materials themselves—such as fiberglass, foam, or reflective barriers—the process of sewing these insulating materials often plays a crucial yet overlooked role in their production and effectiveness.

Understanding Thermal Insulation Materials

Thermal insulation materials work by reducing the transfer of heat between surfaces, ensuring that indoor environments remain comfortable while minimizing energy consumption. The effectiveness of these materials is measured by their thermal resistance, or R-value, which indicates how well the material can resist heat flow. The higher the R-value, the better the insulating performance.

Common insulating materials include fiberglass, cellulose, foam, and mineral wool. Each of these materials has unique properties and characteristics that make them suitable for specific applications. For instance, fiberglass is lightweight and non-combustible, making it ideal for residential insulation. On the other hand, foam insulation offers superior thermal resistance and is often used in commercial buildings and industrial applications.

The Importance of Sewing in Insulation Materials

Sewing becomes an integral part of the manufacturing process, especially when it comes to flexible insulating materials. Many insulation products, such as quilted blankets and custom fit insulation, rely on sewing techniques to assemble various layers of insulation material securely. These sewn products not only enhance thermal performance but also improve durability and ease of installation.

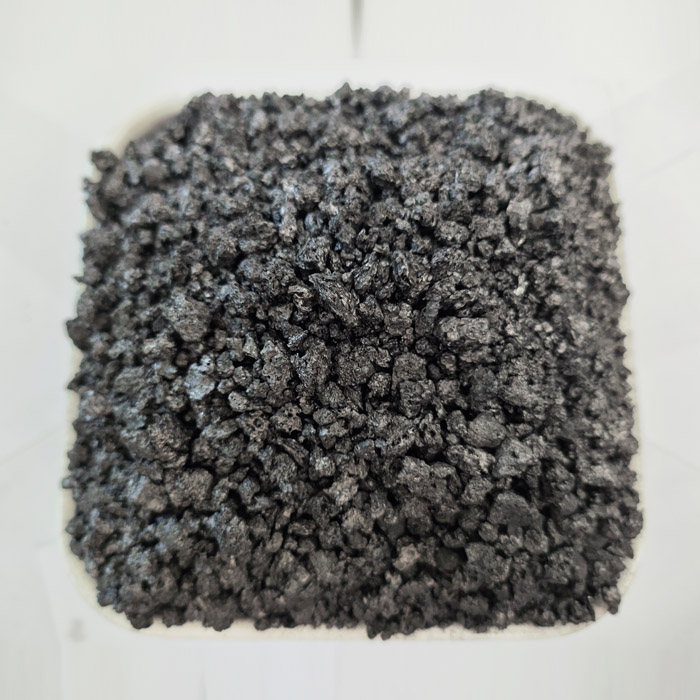

thermal insulation materials sewing

1. Layering for Performance The thermal insulation properties can be significantly enhanced by carefully layering different materials. Sewing enables manufacturers to create multilayer insulation systems that combine various insulating materials. For example, a product might feature a layer of reflective foil sewn between two layers of fiberglass. This configuration not only traps air and reduces heat transfer but also reflects radiant energy back into the living space.

2. Customization and Fit In many applications, particularly in building construction or automotive interiors, insulation needs to be tailored to fit specific shapes and dimensions. Sewing allows for customization. Manufacturers can create bespoke insulation pieces that fit snugly around pipes, ducts, and irregular surfaces, ensuring that there are no gaps through which heat can escape. This precision is vital in achieving optimal energy efficiency.

3. Durability and Longevity Insulation materials must withstand various environmental factors, including moisture, temperature fluctuations, and physical stress. Sewing enhances the structural integrity of insulation products by securing layers together, preventing delamination over time. The durability of sewn insulation materials ensures they maintain their thermal performance throughout their lifespan.

4. Ease of Installation Insulation products that are sewn into specific shapes or structures can be easier to handle and install. This aspect is particularly beneficial for contractors and builders who seek efficiency on job sites. Ready-to-install insulation pieces can significantly reduce labor time and associated costs, as they are designed for straightforward application.

5. Environmental Considerations The efficient use of materials and energy is a growing concern in the manufacturing sector. By sewing various insulation materials together, manufacturers can optimize the use of resources and reduce waste. Furthermore, many modern insulation products are made from recycled materials, and sewing can help maintain the integrity of these materials while minimizing their environmental footprint.

Conclusion

Sewing plays a pivotal role in the effective production of thermal insulation materials. It allows manufacturers to create high-performance, customized, durable, and easily installable insulation solutions that contribute to energy efficiency and comfort in various applications. As industries continue to prioritize sustainability and performance, the significance of sewing in insulation fabrication will likely grow, leading to innovative products that meet the ever-evolving needs of consumers and industries alike. As we move forward, it's essential to recognize and appreciate the craftsmanship and engineering that goes into creating these seemingly simple yet incredibly impactful thermal insulation solutions.

-

Eco-Friendly Granule Covering Agent | Dust & Caking Control

NewsAug.06,2025

-

Fe-C Composite Pellets for BOF: High-Efficiency & Cost-Saving

NewsAug.05,2025

-

Premium Tundish Covering Agents Exporters | High Purity

NewsAug.04,2025

-

Fe-C Composite Pellets for BOF | Efficient & Economical

NewsAug.03,2025

-

Top Tundish Covering Agent Exporters | Premium Quality Solutions

NewsAug.02,2025

-

First Bauxite Exporters | AI-Optimized Supply

NewsAug.01,2025