Feb . 11, 2025 23:25 Back to list

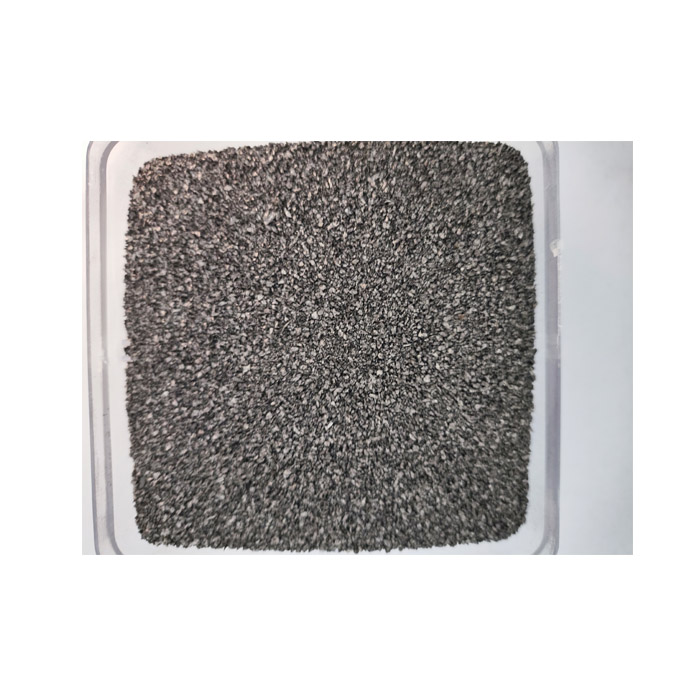

thermally conductive electrically insulating materials

Thermally conductive electrically insulating materials play a pivotal role in various advanced industries, providing solutions for managing heat while ensuring electrical isolation. These materials are critical in applications ranging from electronics and automotive industries to aerospace and renewable energy systems, where efficient heat dissipation and electrical safety are paramount.

Expertise in developing these materials focuses on enhancing their thermal properties while maintaining or improving their insulating capabilities. One strategy involves doping traditional insulating materials with metallic or ceramic particles. When dispersed within polymers or ceramics, these particles create pathways that enable superior heat flow. In the forefront of this innovation, research into carbon-based materials, such as graphene and carbon nanotubes, is garnering momentum. These materials exhibit tremendous potential due to their extraordinary thermal conductivity and flexibility but still face challenges in uniform dispersion and cost-effectiveness. From an authoritative perspective, industry experts recognize that implementing thermally conductive electrically insulating materials is a balancing act that hinges on understanding the specific environmental demands of each application. The integration of these materials requires meticulous attention to factors such as operating temperature range, mechanical stress resistance, and long-term stability under varying environmental conditions. Leading research institutions and companies continuously refine their formulations to meet stringent regulatory standards and performance benchmarks. Trustworthiness in this domain stems from proven application success and documented performance improvements over time. Collaborative efforts between material scientists, product engineers, and end-users ensure that the materials developed not only meet theoretical expectations but also deliver real-world reliability and performance. Manufacturers that consistently engage in thorough testing and third-party validation of their products stand out as authoritative voices in this field. In conclusion, as the demand for smaller, more powerful, and reliable electronic devices escalates, the importance of thermally conductive electrically insulating materials will continue to grow. Their development embodies a cross-disciplinary expertise that combines materials science, engineering know-how, and innovative application. Stakeholders invested in advancing these materials stand to reap significant benefits, not just in terms of enhanced product performance but also in reduced failure rates and increased system longevity, ultimately leading to greater customer satisfaction and market leadership.

Expertise in developing these materials focuses on enhancing their thermal properties while maintaining or improving their insulating capabilities. One strategy involves doping traditional insulating materials with metallic or ceramic particles. When dispersed within polymers or ceramics, these particles create pathways that enable superior heat flow. In the forefront of this innovation, research into carbon-based materials, such as graphene and carbon nanotubes, is garnering momentum. These materials exhibit tremendous potential due to their extraordinary thermal conductivity and flexibility but still face challenges in uniform dispersion and cost-effectiveness. From an authoritative perspective, industry experts recognize that implementing thermally conductive electrically insulating materials is a balancing act that hinges on understanding the specific environmental demands of each application. The integration of these materials requires meticulous attention to factors such as operating temperature range, mechanical stress resistance, and long-term stability under varying environmental conditions. Leading research institutions and companies continuously refine their formulations to meet stringent regulatory standards and performance benchmarks. Trustworthiness in this domain stems from proven application success and documented performance improvements over time. Collaborative efforts between material scientists, product engineers, and end-users ensure that the materials developed not only meet theoretical expectations but also deliver real-world reliability and performance. Manufacturers that consistently engage in thorough testing and third-party validation of their products stand out as authoritative voices in this field. In conclusion, as the demand for smaller, more powerful, and reliable electronic devices escalates, the importance of thermally conductive electrically insulating materials will continue to grow. Their development embodies a cross-disciplinary expertise that combines materials science, engineering know-how, and innovative application. Stakeholders invested in advancing these materials stand to reap significant benefits, not just in terms of enhanced product performance but also in reduced failure rates and increased system longevity, ultimately leading to greater customer satisfaction and market leadership.

Latest news

-

High-Quality Fe-C Alloy Leading Manufacturers & Spherical Alloy Materials Supplier

NewsJun.10,2025

-

Premium Low Nitrogen Recarburiser Supplier & Manufacturer – High Quality Exporters

NewsJun.10,2025

-

DT4 High-Quality Magnetic Materials Leading DT4 Manufacturer & Supplier

NewsJun.10,2025

-

High-Performance Spring Steel Suppliers Custom Solutions

NewsJun.10,2025

-

Premium SWRCH6A Manufacturer Steel Wire Supplier & Factory

NewsJun.10,2025

-

Premium Mild Steel Wire Rod Supplier & Manufacturer

NewsJun.10,2025