Nov . 13, 2024 19:31 Back to list

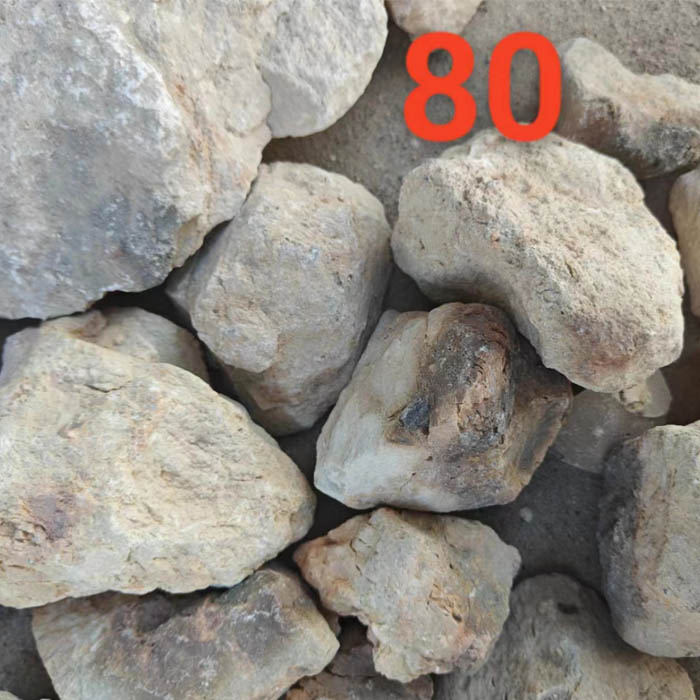

thick sound absorbing material factory

The Role of Thick Sound Absorbing Materials in Modern Industry

In today’s fast-paced world, noise pollution is becoming an increasingly pressing issue. Whether in urban environments or industrial settings, the cacophony of sounds can have detrimental effects on health, productivity, and overall well-being. To combat this challenge, thick sound absorbing materials have emerged as a vital solution, playing a crucial role in creating quieter and more conducive spaces.

Thick sound absorbing materials are designed to absorb sound waves, reducing noise levels in various environments. These materials can be found in a range of applications, from residential and commercial buildings to manufacturing facilities and recording studios. They are particularly effective in mitigating mid to high-frequency sounds, which are often the most disruptive to human activities.

One of the primary advantages of thick sound absorbing materials is their ability to enhance acoustic comfort. In office settings, where concentration is key, excessive noise can hinder productivity. By installing thick sound-absorbing panels or acoustic ceilings, companies can create a more serene working environment. This not only boosts employee satisfaction and performance but also reduces stress levels, contributing to a healthier workplace culture.

In industrial environments, thick sound absorbing materials are equally important. Factories and manufacturing plants often operate machinery that produces significant noise. Prolonged exposure to high noise levels can lead to hearing loss and other health issues for workers. Implementing sound absorbing solutions, such as thick foam panels or specialized acoustic barriers, can help lower noise exposure, ensuring compliance with occupational health regulations and promoting worker safety.

thick sound absorbing material factory

Moreover, thick sound absorbing materials are essential in public spaces as well. Schools, hospitals, and auditoriums can benefit greatly from installing such materials to control sound reverberation and enhance speech intelligibility. In educational settings, for instance, students can better hear their teachers without the interference of background noise, leading to improved learning outcomes.

The manufacturing process of thick sound absorbing materials has also evolved, driven by advancements in technology and material science. Various types of materials, such as fiberglass, mineral wool, and polyurethane foam, are commonly used. Manufacturers are now able to produce these materials in various densities and thicknesses, allowing for tailored solutions that meet specific acoustic requirements. Additionally, many of these materials are environmentally friendly, being made from recycled components or designed for energy efficiency.

As the demand for quietness continues to rise, the thick sound absorbing material industry is poised for growth. Businesses and consumers alike are becoming more aware of the value of sound control in improving quality of life, thereby driving innovation in the field. Manufacturers are focusing on developing more effective materials that not only absorb sound but also contribute to aesthetics and overall interior design.

In conclusion, thick sound absorbing materials are a crucial component in addressing the challenges posed by noise pollution in modern society. Whether in the workplace, industrial settings, or public spaces, their role in enhancing acoustic comfort and safeguarding health cannot be overstated. As technology advances and awareness grows, these materials will continue to evolve, shaping the way we manage sound and noise in our environments for years to come. Embracing these innovations is essential for creating a quieter, more harmonious world.

-

Fe-C Composite Pellets for BOF: Enhance Steelmaking Efficiency

NewsAug.07,2025

-

Eco-Friendly Granule Covering Agent | Dust & Caking Control

NewsAug.06,2025

-

Fe-C Composite Pellets for BOF: High-Efficiency & Cost-Saving

NewsAug.05,2025

-

Premium Tundish Covering Agents Exporters | High Purity

NewsAug.04,2025

-

Fe-C Composite Pellets for BOF | Efficient & Economical

NewsAug.03,2025

-

Top Tundish Covering Agent Exporters | Premium Quality Solutions

NewsAug.02,2025