Aug . 15, 2024 03:28 Back to list

Top Suppliers of Calcined Bauxite for Industrial Applications and Their Key Features Explained

Calcined Bauxite Manufacturers Key Players in the Industry

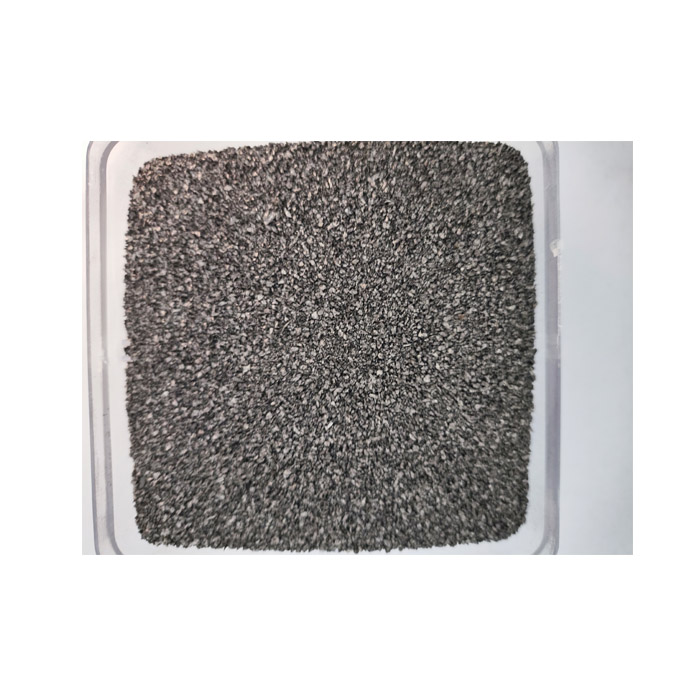

Calcined bauxite, a crucial raw material in various industrial applications, particularly in the manufacturing of refractories, cement, and abrasives, has seen a rise in demand over the past decade. As a result, calcined bauxite manufacturers have become significant players in the global market, providing high-quality products that meet diverse customer needs. This article examines the landscape of calcined bauxite production, key manufacturers, their processes, and the industries they serve.

Understanding Calcined Bauxite

Calcined bauxite is produced by heating bauxite ore to high temperatures (usually between 850°C and 1600°C) in a rotary kiln, where the aluminum hydroxide present in the ore is removed as water vapor, leaving behind a material rich in alumina. The resultant product possesses excellent physical and chemical properties, making it ideal for use in refractories, which are materials that can withstand high temperatures without melting or degrading. Additionally, calcined bauxite has applications in the production of abrasives, as well as in metallurgical industries.

Key Players in the Market

The calcined bauxite manufacturing landscape is dominated by several well-established companies known for their quality, innovation, and operational efficiency. Some of the leading calcined bauxite manufacturers include

1. China Rainbow - One of the largest suppliers of calcined bauxite globally, China Rainbow is recognized for its state-of-the-art production facilities and commitment to sustainable practices. The company's vast experience in the industry allows it to maintain high quality while optimizing production costs.

2. Bauxite Resources Limited - This Australian-based company has carved a niche for itself in the calcined bauxite market. Bauxite Resources is known for its focus on environmental sustainability and for producing low-impurity products, catering to the stringent requirements of industries like refractories.

3. Almatis - A global leader in alumina business, Almatis manufactures calcined bauxite for various applications, including refractories, ceramics, and aluminum. Their extensive portfolio and innovative solutions help them stay ahead in an increasingly competitive market.

calcined bauxite manufacturers

4. SUNDARAM GROUP - Based in India, the Sundaram Group operates several calcined bauxite production units that conform to international quality standards. The company's dedication to research and development enables them to offer customized products tailored to specific industry requirements.

Manufacturing Processes

The production of calcined bauxite begins with high-quality raw bauxite ore, which is crushed and screened to various sizes. The selected bauxite is then fed into rotary kilns where it is heated to the required temperatures. During calcination, the moisture is expelled, and alumina content increases, making it suitable for its intended applications. Once calcined, the product undergoes cooling, further screening, and packaging for distribution.

Manufacturers often invest heavily in modernizing their processes to increase efficiency and minimize environmental impacts. Utilizing energy-efficient kilns and implementing recycling practices within their operations are key strategies adopted by leading manufacturers.

Markets and Applications

The demand for calcined bauxite is expanding across various sectors, primarily in the refractory industry, where it serves as a key ingredient in the manufacture of furnace linings and other heat-resistant materials. Additionally, the cement industry requires calcined bauxite for producing specialized cement formulations, while the abrasive industry uses it in grinding wheels and other abrasive products.

As industries become more innovative and demand higher-quality materials, calcined bauxite manufacturers are likely to play an increasingly vital role in meeting these challenges, ensuring that they remain significant contributors to various sectors, from construction to manufacturing.

In conclusion, calcined bauxite manufacturers are essential players in the industrial landscape. Their ability to provide high-quality products and adapt to the evolving market needs will ensure their sustained relevance and success in the competitive global arena.

-

Eco-Friendly Granule Covering Agent | Dust & Caking Control

NewsAug.06,2025

-

Fe-C Composite Pellets for BOF: High-Efficiency & Cost-Saving

NewsAug.05,2025

-

Premium Tundish Covering Agents Exporters | High Purity

NewsAug.04,2025

-

Fe-C Composite Pellets for BOF | Efficient & Economical

NewsAug.03,2025

-

Top Tundish Covering Agent Exporters | Premium Quality Solutions

NewsAug.02,2025

-

First Bauxite Exporters | AI-Optimized Supply

NewsAug.01,2025