Nov . 20, 2024 13:35 Back to list

traditional recarburiser manufacturers

Traditional Recarburiser Manufacturers An Overview

In the steel and iron industries, the quality and properties of the final products largely depend on the raw materials used during production. One of the crucial materials is carbon, which significantly influences the strength, hardness, and overall performance of steel. As a result, the demand for recarburisers, particularly traditional ones, has seen significant growth. This article delves into the world of traditional recarburiser manufacturers, examining their products, the manufacturing processes used, and the role they play in various industrial applications.

Understanding Recarburisers

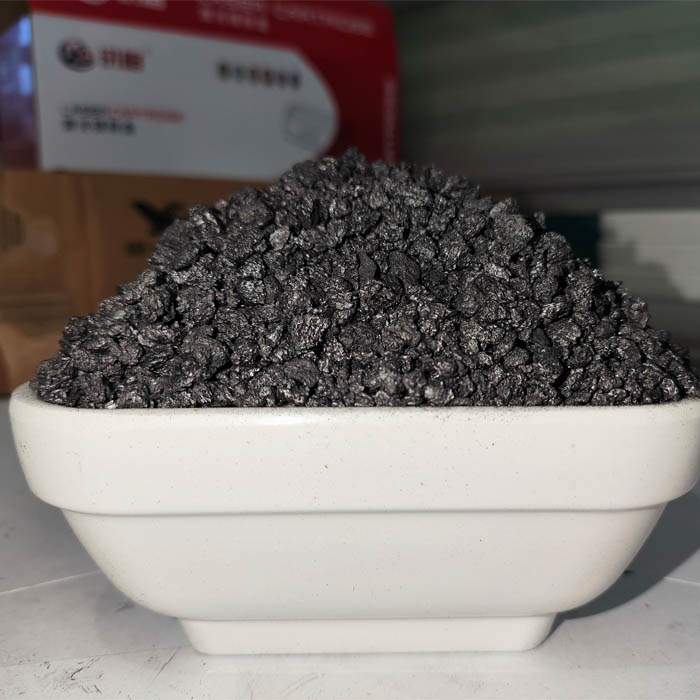

Recarburisers are carbon-rich materials added to molten iron or steel during the melting process. Their primary role is to adjust the carbon content in the metal during production, ensuring that it meets the required specifications for different applications. The types of traditional recarburisers include petroleum coke, anthracite coal, graphite, and char, each with distinct carbon content levels and properties that influence the final product.

The Manufacturing Process

The production of traditional recarburisers involves several steps, including sourcing raw materials, processing, and quality control

. Manufacturers begin by sourcing high-quality raw materials, often from specific geological formations known for their carbon content, such as coal fields or graphite mines.After the raw materials are sourced, they undergo processing, which can include crushing, grinding, and heating to enhance their purity and carbon content. For instance, petroleum coke is produced through the thermal decomposition of petcoke, resulting in a high carbon material used extensively in the steelmaking process.

Once processed, these materials are subjected to rigorous quality control measures to ensure they meet industry standards. Manufacturers often run tests to measure the carbon content, ash levels, and other impurities that could affect the performance of the recarburiser.

Key Players in the Market

The market for traditional recarburisers is characterized by a mix of established companies and smaller manufacturers. Key players often boast decades of experience and a strong reputation for quality. They typically have extensive supply chains and established relationships with steel producers, allowing them to provide consistent and reliable products.

traditional recarburiser manufacturers

Some prominent manufacturers in this space include companies like Asbury Carbons, Graftech International, and Metzer. These companies have built a reputation not just on the quality of their recarburisers but also on their commitment to sustainability and environmental responsibility.

Applications in Industry

Traditional recarburisers are widely used across various industries, most notably in steel and iron production. In the steelmaking process, the right amount of carbon is vital in achieving the desired balance of strength and ductility in the final product. Consequently, the precision with which recarburisers are added to the melt is critical.

Beyond steel manufacturing, recarburisers also play a role in foundries and other sectors where alloys are produced. They are essential in producing ductile iron, where carbon content must be precisely controlled to achieve specific mechanical properties. Additionally, recarburisers are used in the production of chemical feedstocks and in the manufacturing of batteries, particularly in the production of graphite electrodes.

Challenges and Innovations

While traditional recarburiser manufacturers have thrived, they face challenges such as fluctuating raw material prices, competition from synthetic alternatives, and increasing regulatory scrutiny concerning environmental impact.

To address these challenges, many manufacturers are innovating their processes to enhance efficiency and reduce waste. They are also investing in research and development to explore more sustainable sources of carbon, including biomass-derived materials.

Conclusion

Traditional recarburiser manufacturers play a pivotal role in the steel and iron industries, impacting the quality and characteristics of metal products. As they navigate challenges such as market competition and environmental regulations, their commitment to quality and innovation remains paramount. By continuing to refine their processes and explore sustainable practices, these manufacturers will ensure their relevance in an evolving industrial landscape, contributing to the ongoing advancement of metal production technologies. As the demand for high-quality steel and alloys continues to rise, so too will the importance of traditional recarburisers and their manufacturers in meeting global industrial needs.

-

Fe-C Composite Pellets for BOF: Enhance Steelmaking Efficiency

NewsAug.07,2025

-

Eco-Friendly Granule Covering Agent | Dust & Caking Control

NewsAug.06,2025

-

Fe-C Composite Pellets for BOF: High-Efficiency & Cost-Saving

NewsAug.05,2025

-

Premium Tundish Covering Agents Exporters | High Purity

NewsAug.04,2025

-

Fe-C Composite Pellets for BOF | Efficient & Economical

NewsAug.03,2025

-

Top Tundish Covering Agent Exporters | Premium Quality Solutions

NewsAug.02,2025