Aug . 07, 2024 08:35 Back to list

Types of Metal Suppliers and Their Importance in Modern Metallurgy and Manufacturing Industries

The Role of Metal Suppliers in Modern Metallurgy

In the ever-evolving field of metallurgy, the role of metal suppliers is pivotal to the industry’s efficiency and innovation. With the increasing demand for specialized metals across various sectors including construction, automotive, aerospace, and electronics, metal suppliers are tasked with delivering high-quality materials that meet stringent specifications and performance criteria. This article aims to explore the significance of metal suppliers in modern metallurgy, their impact on production processes, and the factors to consider when selecting a reputable supplier.

The Role of Metal Suppliers in Modern Metallurgy

In addition to providing diverse materials, metal suppliers also contribute to the metallurgical process by offering value-added services such as custom fabrication, cutting, welding, and coating. These services enable manufacturers to streamline their operations, reduce waste, and enhance the efficiency of production lines. For example, a metal supplier equipped with advanced machining capabilities can deliver pre-cut metal components directly to manufacturers, saving them valuable time and resources.

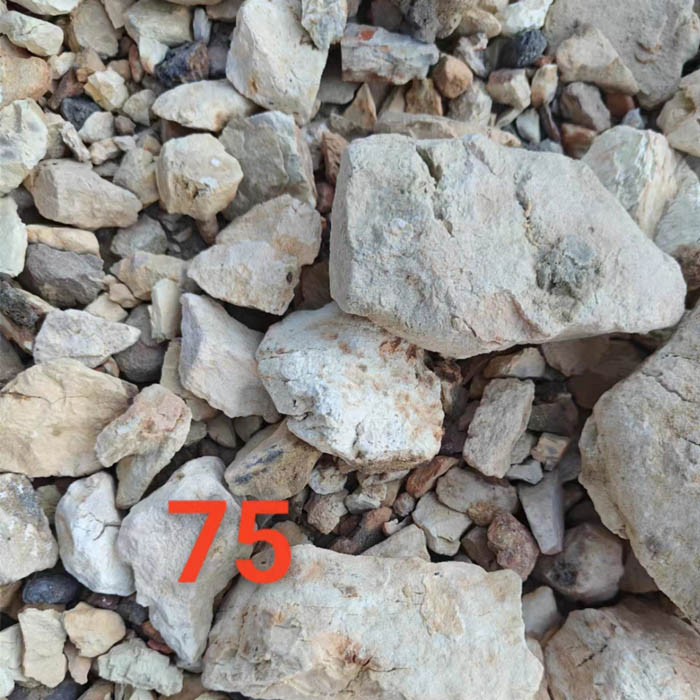

metallurgy 4 metals supplier

Quality assurance is another vital area where metal suppliers play a significant role. In an industry where even minor deviations in material properties can lead to catastrophic failures, the ability to guarantee high-quality materials is paramount. Suppliers often adhere to strict industry standards and certifications, such as ISO or ASTM, ensuring that the materials they supply meet the necessary specifications. This commitment to quality not only protects manufacturers from liability but also enhances their reputation in the marketplace.

The dynamic nature of global markets has led to challenges and opportunities for metal suppliers. Fluctuating metal prices, geopolitical tensions, and supply chain disruptions due to unforeseen events such as pandemics can significantly impact the availability and cost of raw materials. Consequently, suppliers must develop robust relationships with a diverse range of metal producers to mitigate risks and ensure a reliable supply chain. Furthermore, innovation in recycling technologies and sustainable practices has emerged as a key focus area, prompting metal suppliers to incorporate environmentally friendly solutions into their operations.

When selecting a metal supplier, several factors should be taken into consideration. Reliability, quality assurance, and delivery timelines are among the most critical attributes to evaluate. Manufacturers should also consider the supplier’s ability to provide technical support and guidance on material selection, particularly for complex projects that require specialized knowledge. Additionally, building a long-term partnership with a supplier can foster better communication and collaboration, leading to enhanced problem-solving capabilities and innovation.

In conclusion, metal suppliers are vital contributors to the field of metallurgy, influencing the quality and availability of materials necessary for production across various industries. Their role in sourcing, processing, and delivering metals contributes significantly to the overall efficiency and reliability of manufacturing processes. As the demands of modern industry continue to evolve, the importance of selecting the right metal supplier will only grow, positioning them as essential partners in the journey towards technological advancement and sustainable practices in metallurgy. The future of the industry hinges on these collaborations, enabling manufacturers to innovate and thrive in a competitive marketplace.

-

Eco-Friendly Granule Covering Agent | Dust & Caking Control

NewsAug.06,2025

-

Fe-C Composite Pellets for BOF: High-Efficiency & Cost-Saving

NewsAug.05,2025

-

Premium Tundish Covering Agents Exporters | High Purity

NewsAug.04,2025

-

Fe-C Composite Pellets for BOF | Efficient & Economical

NewsAug.03,2025

-

Top Tundish Covering Agent Exporters | Premium Quality Solutions

NewsAug.02,2025

-

First Bauxite Exporters | AI-Optimized Supply

NewsAug.01,2025