Dec . 10, 2024 18:33 Back to list

Vermiculite Manufacturing Process and Its Applications in Modern Industries

Vermiculite Factory A Sustainable Approach to Mineral Processing

Vermiculite is a naturally occurring mineral that has gained immense popularity due to its unique properties and versatile applications. This lightweight, expandable material is used in various industries, including construction, horticulture, and even automotive manufacturing. As the demand for vermiculite continues to rise, the establishment of vermiculite factories becomes increasingly relevant. These factories not only contribute to economic growth but also play a significant role in sustainable development.

A typical vermiculite factory is designed to process raw vermiculite ore, which is primarily extracted from open-pit mines. The ore undergoes several stages of processing to produce the final product. First, the raw ore is crushed and screened to remove impurities. After that, it is subjected to high temperatures in a furnace, where it expands and transforms into a lightweight, porous material. This expansion is due to the water molecules trapped within the mineral structure, which vaporize and cause the vermiculite to pop into its characteristic form.

Vermiculite Factory A Sustainable Approach to Mineral Processing

In addition to its applications in construction, vermiculite is widely used in horticulture. It serves as an ideal growing medium for seedlings and plants due to its ability to retain moisture while allowing for proper aeration. This characteristic promotes healthy root growth, helping plants thrive. Vermiculite is often mixed with soil or other growing media to enhance its water-retaining capacity, making it an essential component for both commercial and home gardening.

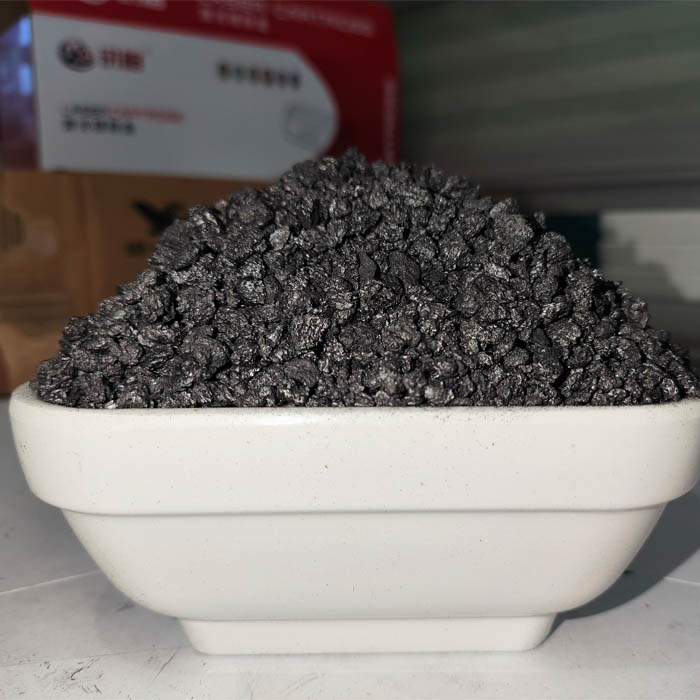

vermiculite factory

Moreover, the automotive industry has also begun to recognize the benefits of vermiculite. Its lightweight nature makes it an excellent choice for insulation in vehicles, helping to enhance fuel efficiency by reducing overall weight. Additionally, vermiculite can be used in the production of soundproofing materials, contributing to a quieter driving experience.

The environmental impact of vermiculite factories is another crucial aspect to consider. By adopting sustainable practices, these facilities can minimize their ecological footprint. For instance, using renewable energy sources for production processes, recycling water, and implementing waste management strategies can significantly reduce environmental harm. Furthermore, responsible mining practices ensure that natural habitats are preserved, and local ecosystems remain intact.

Community engagement is also vital for vermiculite factories. By collaborating with local stakeholders, these facilities can create job opportunities and contribute to the regional economy. Educational initiatives can be established to raise awareness about the benefits of vermiculite and its applications, fostering a sense of community involvement.

In conclusion, vermiculite factories represent a significant advancement in mineral processing that aligns with sustainable practices. By producing a material with diverse applications, these factories not only meet the growing market demands but also contribute to energy efficiency and resource conservation. As industries continue to evolve, the role of vermiculite in construction, horticulture, and automotive manufacturing will likely expand, making vermiculite factories an essential part of a sustainable future.

-

Eco-Friendly Granule Covering Agent | Dust & Caking Control

NewsAug.06,2025

-

Fe-C Composite Pellets for BOF: High-Efficiency & Cost-Saving

NewsAug.05,2025

-

Premium Tundish Covering Agents Exporters | High Purity

NewsAug.04,2025

-

Fe-C Composite Pellets for BOF | Efficient & Economical

NewsAug.03,2025

-

Top Tundish Covering Agent Exporters | Premium Quality Solutions

NewsAug.02,2025

-

First Bauxite Exporters | AI-Optimized Supply

NewsAug.01,2025