Ago . 21, 2024 15:18 Back to list

Raw Materials Suppliers for High-Quality Refractory Bricks Manufacturing Process

Understanding the Landscape of Refractory Bricks Raw Materials Manufacturers

In the realm of industrial production, refractory materials play a crucial role, particularly in processes that involve high temperatures. Refractory bricks are essential components used in various industries, including metallurgy, glass, cement, and ceramics, among others. The demand for high-quality refractory bricks has led to a burgeoning market for raw materials, underpinning the operations of manufacturers in this vital sector.

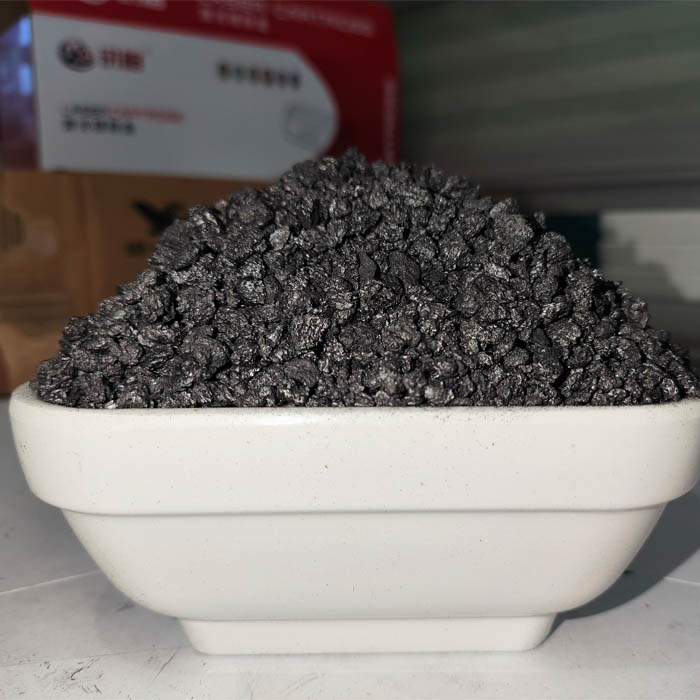

Refractory bricks are made from various raw materials that can withstand extreme temperatures while maintaining structural integrity. The primary materials used in the production of these bricks include alumina, silica, magnesia, and other oxides. Each of these materials contributes unique properties that enhance the performance and durability of the final product. For instance, alumina-based refractories are well-known for their high-temperature resistance and mechanical strength, making them ideal for use in furnaces and kilns.

The manufacturing process of refractory bricks involves the careful selection and preparation of these raw materials. Manufacturers must ensure that their raw materials meet stringent quality standards to produce bricks that can withstand the harsh conditions they will encounter. This includes evaluating the chemical composition, particle size distribution, and physical properties of the materials. Consequently, manufacturers often rely on a network of suppliers to source high-quality raw materials, which can significantly influence their production costs and the performance of the final products.

One of the key challenges faced by manufacturers in the refractory brick market is the fluctuation in the prices of raw materials. Many of these materials are sourced from mines or quarries, subjecting them to market volatility. Furthermore, geopolitical factors and environmental regulations can impact supply chains, leading to potential disruptions and increased costs. Manufacturers are increasingly exploring alternative raw materials or developing new formulations to mitigate these risks and enhance the sustainability of their operations.

refractory bricks raw materials manufacturers

In addition to sourcing raw materials, refractory bricks manufacturers are also investing in research and development to innovate and improve their products. Advances in material science are leading to the creation of refractory bricks that not only withstand higher temperatures but also offer enhanced thermal efficiency and lower thermal conductivity. These innovations are particularly relevant in industries aiming to reduce energy consumption and minimize environmental impact.

It is also important to recognize the role of technology in the manufacturing process. The advent of automation and advanced manufacturing techniques has enabled manufacturers to optimize production efficiency and product quality. By employing sophisticated testing methods, manufacturers can ensure that the raw materials used in their refractory bricks meet the necessary specifications, leading to improved performance in high-temperature applications.

As businesses increasingly focus on sustainability and reducing their carbon footprint, manufacturers in the refractory brick sector are also prioritizing eco-friendly practices. This includes recycling waste materials from other industrial processes into new refractory products or using more sustainable sources of raw materials. Such initiatives not only enhance the environmental profile of manufacturers but also appeal to customers who are increasingly conscious of their supply chain sustainability.

In conclusion, the landscape of refractory bricks raw materials manufacturers is shaped by the complex interplay of material selection, technological advancements, and market dynamics. With the increasing demand for high-quality refractory bricks across various industries, manufacturers must navigate challenges such as raw material sourcing, price volatility, and sustainability. By focusing on innovation and efficiency, they can position themselves as key players in this critical sector of industrial production. As industries continue to evolve and require more advanced materials, the role of refractory bricks manufacturers will only become more significant in meeting these demands.

-

High-Quality Fe-C Alloy Leading Manufacturers & Spherical Alloy Materials Supplier

NewsJun.10,2025

-

Premium Low Nitrogen Recarburiser Supplier & Manufacturer – High Quality Exporters

NewsJun.10,2025

-

DT4 High-Quality Magnetic Materials Leading DT4 Manufacturer & Supplier

NewsJun.10,2025

-

High-Performance Spring Steel Suppliers Custom Solutions

NewsJun.10,2025

-

Premium SWRCH6A Manufacturer Steel Wire Supplier & Factory

NewsJun.10,2025

-

Premium Mild Steel Wire Rod Supplier & Manufacturer

NewsJun.10,2025