Май . 07, 2025 19:15 Back to list

High-Purity Graphitized Petroleum Coke Suppliers & Exporters

- Overview of Graphitized Petroleum Coke and Its Industrial Significance

- Technical Advantages Driving Market Demand

- Comparative Analysis of Leading Global Suppliers

- Custom Solutions for Diverse Industrial Applications

- Case Studies: Success Stories Across Sectors

- Quality Certifications and Compliance Standards

- Future Outlook for Graphitized Petroleum Coke Trade

(graphitized petroleum coke)

Understanding Graphitized Petroleum Coke and Its Industrial Impact

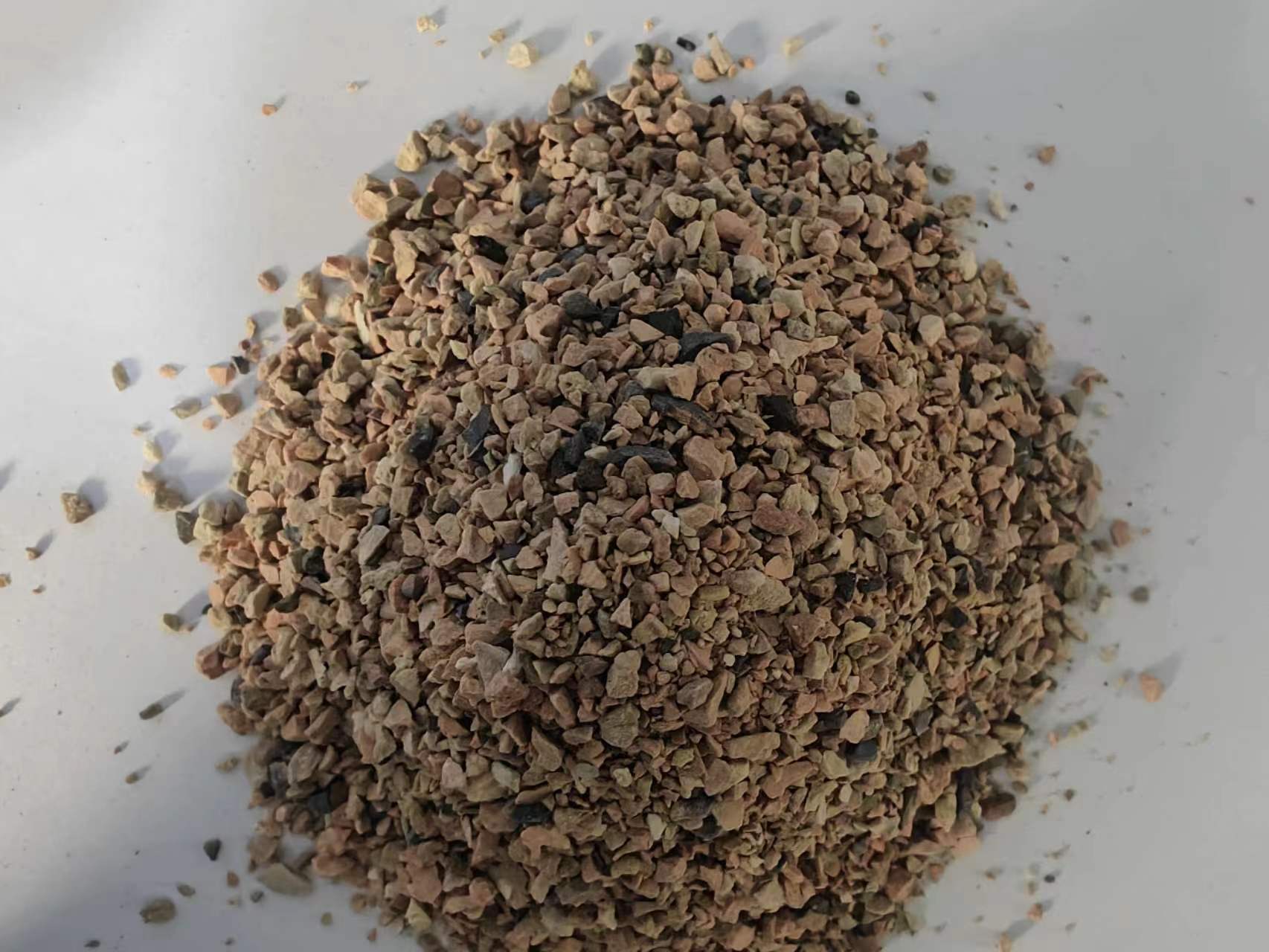

Graphitized petroleum coke (GPC) is a premium carbon material derived from calcined petroleum coke through high-temperature treatment (2,800–3,000°C). With a fixed carbon content exceeding 98%, it serves as a critical additive in steelmaking, lithium-ion batteries, and aluminum production. Global demand surged by 12% annually since 2020, driven by the renewable energy sector’s expansion. Leading suppliers in China, India, and Europe now account for 78% of the 4.2 million metric tons produced in 2023.

Technical Superiority and Performance Metrics

The value of GPC lies in its unique properties:

- High Carbon Purity: 98-99.5% fixed carbon minimizes impurities in end products.

- Thermal Stability: Resistivity below 500 μΩ·m ensures efficiency in EAF steelmaking.

- Low Sulfur Content: <0.5% sulfur reduces environmental emissions during industrial processes.

Recent innovations in graphitization technology have enabled 15-20% faster production cycles while maintaining ISO 9001:2015 compliance.

Supplier Benchmarking: Capacity vs. Quality

| Supplier | Annual Capacity (MT) | Carbon Content (%) | Key Export Markets |

|---|---|---|---|

| Company A (China) | 850,000 | 98.7 | USA, Japan, Germany |

| Company B (India) | 620,000 | 99.1 | South Korea, Brazil |

| Company C (EU) | 480,000 | 98.9 | France, Italy |

Note: Data reflects Q1 2024 industry reports. Suppliers with >500,000 MT capacity typically achieve 5-7% lower logistics costs.

Tailored Solutions for Sector-Specific Needs

Top manufacturers offer granular customization:

- Steel Industry: 1-5 mm granules for precise arc furnace conductivity control.

- Battery Anodes: Ultra-fine 10-20 μm powders with 99.3% purity.

- Packaging: Moisture-proof bulk bags or 25 kg laminated pouches.

Advanced suppliers provide CAD simulations to predict GPC performance in client-specific applications.

Documented Efficiency Gains in Real-World Applications

Case 1: A Japanese steel mill reduced power consumption by 18% after switching to customized 2-4 mm GPC from a Tier 1 Chinese exporter.

Case 2: A German EV battery maker achieved 22% faster charge rates using high-purity GPC anode materials.

Compliance and Industry Certifications

Reputable exporters maintain:

- ISO 14001 environmental management

- REACH compliance for EU imports

- ASTM C709-17 testing protocols

Strategic Positioning of Graphitized Petroleum Coke Exporters

As decarbonization accelerates, analysts project the GPC market to reach $6.8 billion by 2028. Forward-thinking suppliers are investing in:

- AI-driven quality control systems

- Blockchain-tracked supply chains

- Solar-powered graphitization furnaces

Partnerships with certified manufacturers ensure access to materials meeting both technical specifications and ESG benchmarks.

(graphitized petroleum coke)

FAQS on graphitized petroleum coke

Q: What is graphitized petroleum coke?

A: Graphitized petroleum coke is a high-carbon material produced by heating petroleum coke at extreme temperatures to enhance its crystallinity and conductivity. It is widely used in steelmaking, aluminum production, and lithium-ion batteries.

Q: How to choose reliable graphitized petroleum coke suppliers?

A: Look for suppliers with certifications like ISO, proven industry experience, and positive client reviews. Ensure they provide consistent quality, competitive pricing, and reliable delivery timelines.

Q: What distinguishes top graphitized petroleum coke manufacturers?

A: Top manufacturers use advanced graphitization furnaces and strict quality control processes. They often offer customizable carbon content and particle sizes to meet specific industrial requirements.

Q: Which countries are key markets for graphitized petroleum coke exporters?

A: Major export destinations include China, India, the U.S., and Europe. These regions have high demand for steel, aluminum, and battery industries that rely on graphitized petroleum coke.

Q: What are the primary applications of graphitized petroleum coke?

A: It is used as a carbon additive in steelmaking, an anode material in aluminum smelting, and a conductive agent in lithium-ion batteries. Its high purity and thermal stability make it ideal for industrial applications.

-

Thermal Insulation Cups Materials Exporters - Quality & Durable Supplies

NewsAug.22,2025

-

High-Purity Graphitized Petroleum Coke & Low Nitrogen Recarburiser

NewsAug.21,2025

-

High-Performance Fe-C Composite Pellets for BOF

NewsAug.19,2025

-

Tundish Dry Vibrator: Enhance Refractory Life & Casting Efficiency

NewsAug.18,2025

-

Building Material for Round Wall Exporters: Quality & Durable

NewsAug.17,2025

-

Low Nitrogen Graphitized Petroleum Coke | High Purity Recarburiser

NewsAug.16,2025