Sep . 16, 2024 08:10 Back to list

Converter Steel Making Factory - High-Quality Steel Production

The Evolution and Significance of Converter Steel Making in Modern Metallurgy

Steelmaking has undergone a revolutionary transformation over the past century, with the converter method emerging as a cornerstone of modern metallurgy. Recognizing its pivotal role not only in industrial applications but also in shaping the economies and infrastructures of nations, the converter steel making process has proven to be both efficient and sustainable.

The Evolution and Significance of Converter Steel Making in Modern Metallurgy

The advantages of the converter method are numerous. Firstly, it allows for the production of steel with precise compositions tailored to specific applications. High-quality steels can be produced for various sectors, including automotive, construction, and manufacturing, each requiring unique properties. Additionally, the converter process is considerably more efficient than traditional methods, such as open hearth furnaces, which are now largely obsolete. The energy consumption in a BOF is significantly lower, and its ability to utilize scrap metal contributes to recycling efforts and reduces the need for virgin raw materials.

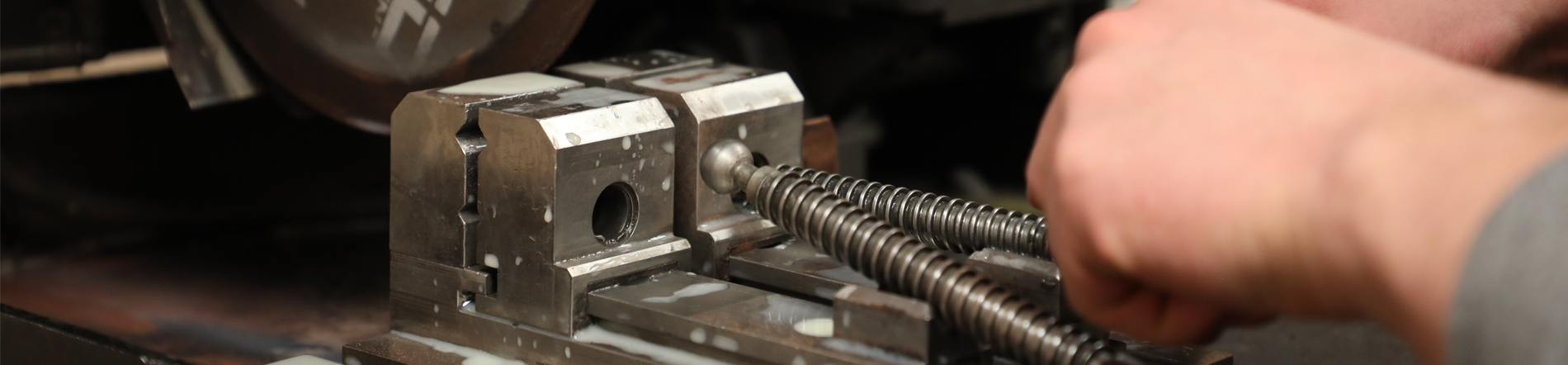

converter steel making factory

Moreover, converter steel making aligns with modern sustainability goals. The integration of scrap steel into the BOF process minimizes waste and lowers the carbon footprint associated with steel production. Companies are also investing in technologies to capture and use the emissions generated during the process, enhancing the environmental viability of steel manufacturing. This commitment to sustainable practices is pivotal as the global community strives to address climate change and reduce greenhouse gas emissions.

The converter steelmaking process also offers notable economic advantages. By optimizing resource use and reducing operational costs, steel manufacturers can enhance their competitiveness in the global market. The ability to produce large quantities of high-quality steel efficiently contributes to lower prices and increased availability, benefiting industries that rely heavily on steel as a primary raw material.

In addition to its technical and environmental benefits, the shift to converter steel making has had a profound social impact. It has created jobs not only in steel production but also in related sectors such as transportation, logistics, and manufacturing. The rise of steelmaking technologies has fostered innovation and growth, propelling economies forward and supporting advancements in infrastructure development.

In conclusion, converter steelmaking stands as a testament to the ingenuity of modern industrial practices. Its blend of efficiency, quality, and sustainability makes it an essential process in meeting the world's growing demand for steel. As the foundation of numerous infrastructures and applications, the ongoing evolution of converter steelmaking will undoubtedly play a crucial role in shaping the future of metallurgy and global economies for years to come.

-

Ladle Covering Agent Suppliers Heat-Resistant & Durable Solutions

NewsMay.08,2025

-

High-Efficiency Steel Converters Reliable Supplier & Manufacturer

NewsMay.08,2025

-

Premium Carburizer Manufacturer High-Carbon Solutions for Steel & Foundry

NewsMay.08,2025

-

Top Sewage Treatment Solutions Trusted Manufacturer & Supplier

NewsMay.07,2025

-

SWRCH15A Cold Heading Steel Wire Rods High Strength & Precision

NewsMay.07,2025

-

High-Strength Tire Cord Steel Trusted Suppliers & Exporters

NewsMay.07,2025