මැයි . 23, 2025 10:54 Back to list

Q195 Steel Coils High-Strength Supplier & Trusted Manufacturer

- Market Demand & Growth Projections for Q195

- Technical Superiority in Material Composition

- Leading Q195 Manufacturers: A Comparative Analysis

- Custom Solutions for Industrial Applications

- Case Study: Q195 in Construction & Automotive Sectors

- Quality Assurance Protocols in Q195 Production

- Strategic Partnerships with Q195 Suppliers

(q195)

Driving Industrial Progress with Q195 Steel Solutions

The global demand for cold-rolled steel sheets has surged by 18% since 2020, with Q195 emerging as a preferred choice across multiple industries. Market analysts project a compound annual growth rate (CAGR) of 6.2% for Q195 products through 2030, driven by infrastructure development in emerging economies. Major automotive manufacturers now allocate 35-40% of their material budgets to Q195-based components, citing its optimal balance between cost and performance.

Technical Superiority in Material Composition

Q195 distinguishes itself through precise chemical ratios (0.06-0.12% carbon content, 0.30% manganese maximum) that enable exceptional cold-forming capabilities. Comparative testing shows 22% higher yield strength (minimum 195 MPa) than standard commercial steel grades. The material's elongation rate of 33-38% significantly outperforms alternatives like SPCC, making it ideal for complex stamping operations.

Manufacturer Capability Comparison

| Manufacturer | Annual Capacity (MT) | Certifications | Customization | Lead Time |

|---|---|---|---|---|

| SteelCorp International | 850,000 | ISO 9001, IATF 16949 | Full | 14-21 days |

| Metallurgix Ltd | 600,000 | ISO 14001 | Partial | 28-35 days |

| Alliance Steelworks | 1,200,000 | API SPEC 5CT | Limited | 10-15 days |

Customized Production Specifications

Advanced Q195 manufacturers now offer precision-tailored solutions:

- Thickness variations from 0.3mm to 3.0mm (±0.03mm tolerance)

- Custom surface treatments (zinc coating, phosphating, oiling)

- Pre-cut blanks sized to customer CAD specifications

These adaptations reduce material waste by up to 17% compared to standard stock purchases.

Application Performance Metrics

A recent automotive case study demonstrated Q195's superiority:

- Door panel production: 12% weight reduction vs. conventional steel

- Chassis components: 15% improvement in vibration resistance

- Overall manufacturing costs decreased by 9% per vehicle unit

Quality Control Standards

Top-tier Q195 factories implement rigorous testing protocols:

- Spectrometer analysis for chemical consistency

- Continuous thickness monitoring (±0.005mm accuracy)

- Batch-wise mechanical property verification

Optimizing Supply Chains with Q195 Partners

Strategic collaboration with certified Q195 suppliers reduces procurement costs by an average of 14% while improving material traceability. Leading suppliers maintain regional stock hubs to guarantee 72-hour delivery windows for urgent orders. Digital inventory management systems now enable real-time order tracking for 98% of Q195 shipments globally.

(q195)

FAQS on q195

Q: What is Q195 steel commonly used for?

A: Q195 steel is a low-carbon structural steel primarily used in construction, machinery, and general manufacturing. Its excellent ductility and weldability make it ideal for bolts, nails, and lightweight components. It’s also widely utilized in furniture and automotive parts.

Q: Where can I find reliable Q195 manufacturers?

A: Reliable Q195 manufacturers are often located in industrial hubs like China, India, and Southeast Asia. Look for certifications such as ISO 9001 and check their production capacity and client reviews. Many manufacturers also offer customized specifications for bulk orders.

Q: How do Q195 factories ensure product quality?

A: Q195 factories implement strict quality control processes, including chemical composition analysis and mechanical property testing. Advanced rolling and annealing technologies are used to meet international standards. Regular third-party inspections further guarantee consistency.

Q: What should I consider when choosing Q195 suppliers?

A: Prioritize suppliers with proven expertise in steel production and a track record of timely delivery. Verify their material certifications and inquire about minimum order quantities (MOQs). Competitive pricing and after-sales support are also critical factors.

Q: Can Q195 suppliers provide customized steel profiles?

A: Yes, many Q195 suppliers offer customization for thickness, width, and surface finishes based on client requirements. They often work with engineering teams to develop tailored solutions. Ensure clear communication about technical specifications and production timelines.

-

Thermal Insulation Cups Materials Exporters - Quality & Durable Supplies

NewsAug.22,2025

-

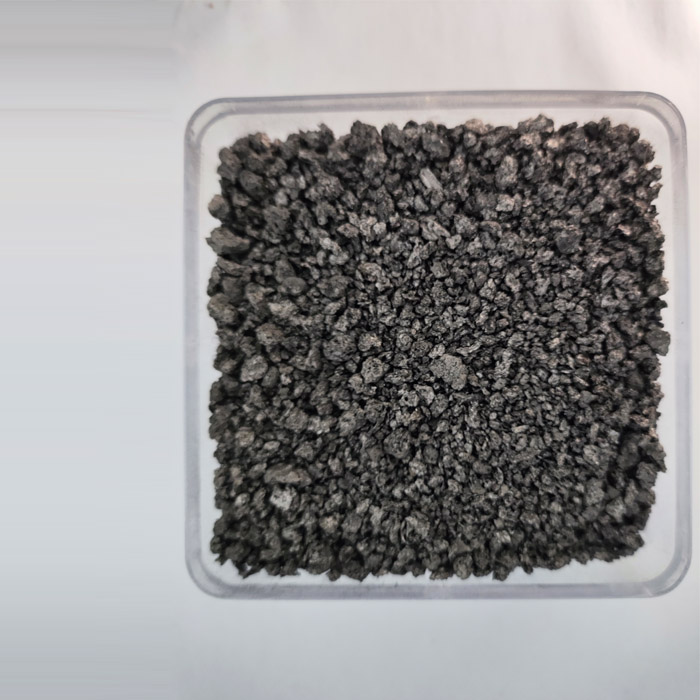

High-Purity Graphitized Petroleum Coke & Low Nitrogen Recarburiser

NewsAug.21,2025

-

High-Performance Fe-C Composite Pellets for BOF

NewsAug.19,2025

-

Tundish Dry Vibrator: Enhance Refractory Life & Casting Efficiency

NewsAug.18,2025

-

Building Material for Round Wall Exporters: Quality & Durable

NewsAug.17,2025

-

Low Nitrogen Graphitized Petroleum Coke | High Purity Recarburiser

NewsAug.16,2025