Nov . 24, 2024 07:23 Back to list

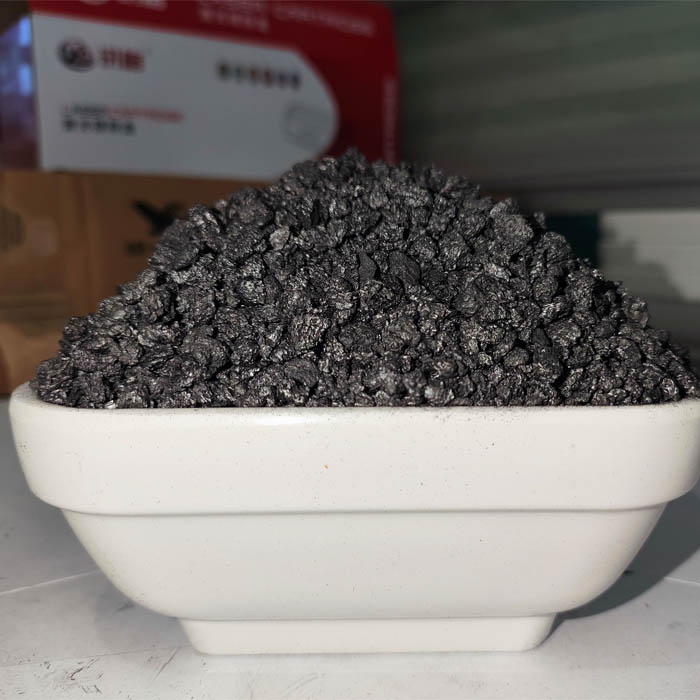

aggregates for lightweight concrete factory

The Role of Aggregates in Lightweight Concrete Production

In the realm of construction materials, lightweight concrete has gained significant attention for its numerous advantages over traditional concrete. One of the primary factors contributing to the properties of lightweight concrete is the type and quality of aggregates used in its formulation. This article explores the crucial role of aggregates in lightweight concrete production, focusing on the types of aggregates, their benefits, and their applications in modern construction.

Understanding Lightweight Concrete

Lightweight concrete is defined by its reduced density, which typically ranges from 1,600 to 1,800 kg/m³, compared to the standard concrete density of about 2,400 kg/m³. This reduction in weight does not compromise the structural integrity of the material; rather, it enhances certain properties, making lightweight concrete an ideal choice for various construction applications, such as precast elements, structural systems, and insulating panels.

Types of Aggregates

Aggregates used in lightweight concrete are categorized into two main types lightweight natural aggregates and lightweight artificial aggregates.

1. Lightweight Natural Aggregates These include materials such as pumice, expanded clay, expanded shale, and volcanic ash. These aggregates possess a porous structure, allowing for lower density while maintaining adequate strength. Their natural origins also mean they are often more environmentally friendly compared to artificial options.

2. Lightweight Artificial Aggregates Produced through various processes, these aggregates include expanded polystyrene (EPS) beads, glass beads, and other synthetic materials. They offer exceptional thermal insulation properties and can be engineered to meet specific design criteria.

Benefits of Lightweight Aggregates

aggregates for lightweight concrete factory

The inclusion of lightweight aggregates in concrete mixes offers numerous benefits, including

- Reduced Weight The most apparent advantage is the decreased weight of the final concrete product. This characteristic helps reduce the overall load on structural elements such as beams and slabs, potentially allowing for lighter supporting structures. - Improved Insulation Properties Many lightweight aggregates have good thermal insulation properties. This results in structures that are more energy-efficient, as they can maintain consistent internal temperatures and reduce heating and cooling costs.

- Enhanced Workability Lightweight concrete mixtures tend to be more workable than traditional concrete due to the lower density and improved flow characteristics of lightweight aggregates. This property allows for easier handling and placement during the construction process.

- Versatility Lightweight concrete can be tailored for various applications, including load-bearing and non-load-bearing elements. Its high strength-to-weight ratio makes it suitable for building components that require both durability and lower weight.

Applications in Modern Construction

The increasing demand for energy-efficient and sustainable building practices has led to a rise in the use of lightweight concrete in various applications. From residential buildings to commercial structures, lightweight concrete is being utilized for walls, slabs, roofs, and even for elements like precast barriers.

In high-rise buildings, it plays a crucial role in reducing the weight of structural components, thereby minimizing the need for robust foundations and enabling taller builds. Additionally, in projects seeking green building certifications, lightweight concrete’s favorable thermal properties contribute to overall energy efficiency.

Conclusion

The production of lightweight concrete is heavily reliant on the choice and quality of aggregates. By selecting the appropriate lightweight aggregates, manufacturers can produce concrete that not only meets structural requirements but also enhances energy efficiency and sustainability. As the construction industry continues to evolve, the role of aggregates will remain central to advancing lightweight concrete technology and its applications, ultimately shaping the future of modern architecture.

-

High-Quality Fe-C Alloy Leading Manufacturers & Spherical Alloy Materials Supplier

NewsJun.10,2025

-

Premium Low Nitrogen Recarburiser Supplier & Manufacturer – High Quality Exporters

NewsJun.10,2025

-

DT4 High-Quality Magnetic Materials Leading DT4 Manufacturer & Supplier

NewsJun.10,2025

-

High-Performance Spring Steel Suppliers Custom Solutions

NewsJun.10,2025

-

Premium SWRCH6A Manufacturer Steel Wire Supplier & Factory

NewsJun.10,2025

-

Premium Mild Steel Wire Rod Supplier & Manufacturer

NewsJun.10,2025