செப் . 21, 2024 17:18 Back to list

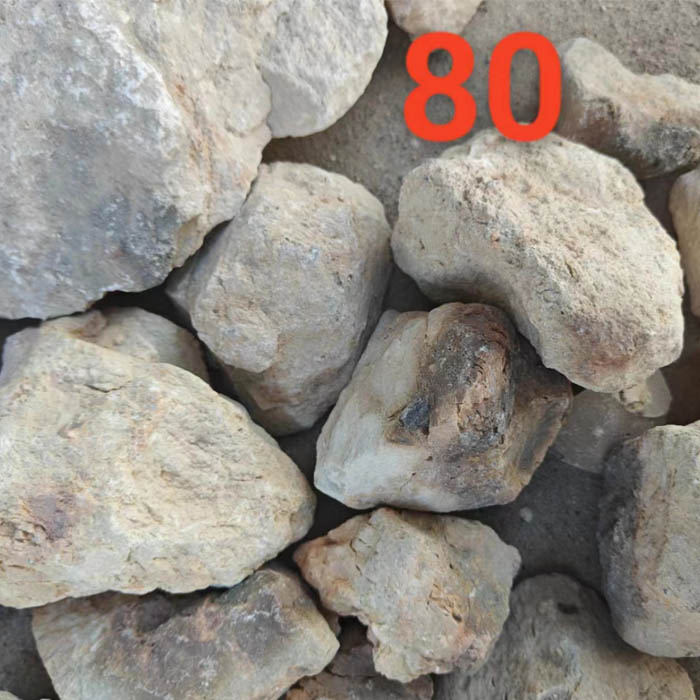

petroleum coke producers factory

The Role of Petroleum Coke Producers in the Energy Sector

Petroleum coke, commonly referred to as petcoke, is a carbon-rich solid material that is produced as a byproduct during the oil refining process. As the demand for energy continues to rise globally, the role of petroleum coke producers has become increasingly significant. This article will explore the production process, applications, and the challenges faced by petcoke manufacturers in today's environmental landscape.

Production Process

The production of petroleum coke begins in the coker unit of an oil refinery, where heavy crude oil is subjected to high temperatures and pressure. This process breaks down the heavier fractions of crude oil into lighter products like gasoline and diesel. The remaining materials undergo thermal cracking, leading to the formation of petroleum coke. The resulting petcoke can be categorized into two main types green petcoke, which is uncalcinated and contains volatile matter, and calcined petcoke, which is produced by heating green petcoke to higher temperatures to remove impurities and enhance its carbon content. Calcined petcoke is particularly valuable in various industrial applications.

Applications of Petroleum Coke

The versatility of petroleum coke makes it suitable for a wide array of applications. One of the primary uses of calcined petroleum coke is in the production of anodes for aluminum smelting. The aluminum industry relies heavily on high-quality anodes to facilitate the electrolysis process. Additionally, petcoke is utilized as a fuel source in cement kilns, power plants, and various industrial processes due to its high calorific value and low sulfur content.

petroleum coke producers factory

Furthermore, petcoke has found its way into the manufacturing of electrodes for the steel and titanium industries. Its high carbon content and conductivity make it an excellent material for producing anodes and cathodes in industrial applications. The growing demand for aluminum and steel, driven by infrastructure projects and automotive industries, has further boosted the market for petroleum coke.

Environmental Challenges

Despite its economic advantages, the petroleum coke industry faces significant environmental challenges. The production and combustion of petcoke can contribute to air pollution, releasing harmful emissions such as sulfur dioxide and particulate matter. As a result, regulatory bodies are imposing stricter environmental regulations, prompting manufacturers to adopt cleaner production techniques and explore carbon capture and storage technologies.

Moreover, the disposal of green petcoke presents a challenge, as improperly stored or managed petcoke can lead to environmental contamination. Companies must implement effective waste management practices to minimize their ecological footprint, ensuring that their operations align with sustainable development goals.

Conclusion

Petroleum coke producers play a crucial role in the energy sector, providing essential materials for various industrial applications. The intersection of growing global energy demands and environmental concerns presents both opportunities and challenges for petcoke manufacturers. As the industry evolves, innovation and sustainable practices will be key to ensuring that petroleum coke remains a viable resource while minimizing its impact on the environment. With the right strategies, petroleum coke production can thrive in a future that prioritizes both economic growth and sustainability.

-

Premium Ladle Covering Agent Extended Steel Protection & Efficiency

NewsJun.05,2025

-

Premium Liquid Steel Suppliers & Manufacturers Global Exporters

NewsJun.05,2025

-

Top Particle & Ladle Covering Agent Quality Supplier

NewsJun.05,2025

-

SWRCH15K Manufacturers - High-Strength Steel Components

NewsJun.04,2025

-

Premium Coarse Vermiculite Supplier High-Performance Insulation

NewsJun.04,2025

-

Premium Covering Flux Suppliers & Exporters Top Manufacturer

NewsJun.04,2025