Dec . 11, 2024 23:53 Back to list

green delayed petroleum coke manufacturer

The Impact of Green Delayed Petroleum Coke Manufacturing on the Environment

In recent years, the manufacturing processes of various industrial materials have come under scrutiny due to their environmental ramifications. One such material, petroleum coke, has gained attention for its significant contributions to energy production and carbon emissions. However, as the demand for sustainable practices calls for change, the concept of green delayed petroleum coke manufacturing is emerging as a promising alternative.

Understanding Petroleum Coke

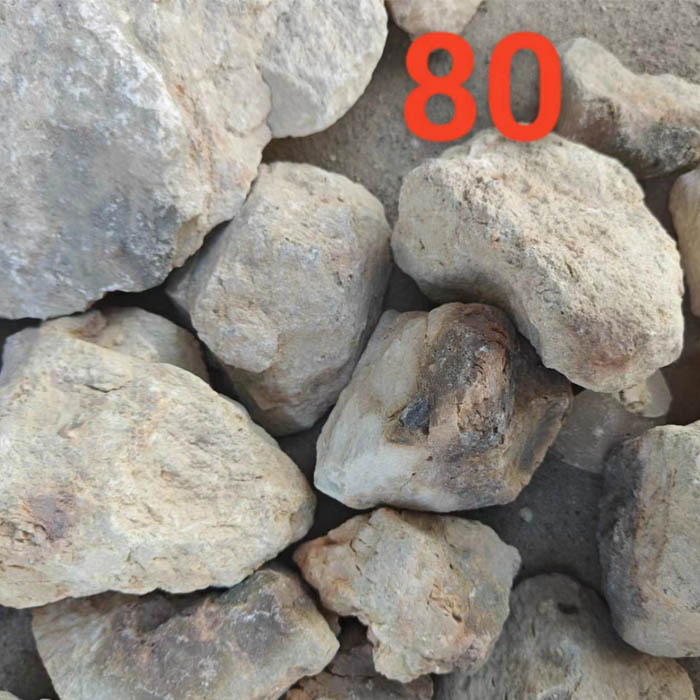

Petroleum coke, often referred to as petcoke, is a byproduct of the oil refining process. It is produced during the delayed coking process, where heavy crude oil is thermally cracked to yield lighter oils and petroleum coke. This material is primarily used as a fuel source in cement kilns, power plants, and aluminum production due to its high energy content. However, its combustion results in considerable carbon emissions, contributing to global warming and air quality issues.

The Shift Toward Sustainability

The urgency of addressing climate change has necessitated a shift towards more sustainable industrial practices. The petroleum industry is no exception. As energy producers and manufacturers explore greener alternatives, the manufacturing of delayed petroleum coke is evolving. This “green” approach involves enhancing production practices to minimize environmental impacts while still meeting market demands.

Innovations in Green Delayed Coke Manufacturing

Several innovative strategies are being implemented in the production of green delayed petroleum coke. Key among these is the integration of renewable energy sources into the manufacturing process. By utilizing solar, wind, or bioenergy solutions, producers can significantly reduce their carbon footprint during production.

Another significant development is the optimization of the delayed coking process itself. Traditional methodologies can result in large volumes of greenhouse gases; however, advancements in technology allow for more efficient thermal cracking techniques. These processes not only enhance the yield of petroleum coke but also lower the emissions associated with its production.

Moreover, the utilization of carbon capture and storage (CCS) technologies is becoming increasingly prevalent in the petroleum industry

. By capturing CO2 emissions during petroleum coke production and storing them underground, manufacturers can mitigate the overall carbon output of their operations.green delayed petroleum coke manufacturer

Environmental Benefits

Transitioning to green delayed petroleum coke manufacturing provides numerous environmental benefits. One of the most significant is the reduction in greenhouse gas emissions. As manufacturers adopt cleaner technologies and renewable energy sources, the carbon footprint of petcoke production decreases, contributing to global climate goals.

Additionally, the push for sustainability emphasizes the responsible sourcing of feedstocks used in the production of delayed petroleum coke. This includes monitoring and managing the environmental impacts of oil extraction and refining processes, thereby promoting more sustainable practices throughout the petroleum supply chain.

Economic Considerations

While the transition to green delayed petroleum coke manufacturing presents clear environmental advantages, it also raises several economic considerations. Initial investments in new technologies and processes can be substantial. However, stakeholders in the petroleum industry are increasingly recognizing that sustainability can lead to long-term cost savings. By improving energy efficiency and reducing emissions-related liabilities, producers can enhance their bottom line.

Furthermore, as regulatory frameworks become stricter regarding emissions, companies that proactively adopt greener practices may find themselves at a competitive advantage. The emerging market for environmentally friendly products is poised for growth, and early adopters of green technology could establish themselves as leaders in this new landscape.

Conclusion

As the global economy transitions towards sustainable practices, the manufacturing of delayed petroleum coke stands at a crossroads. The emergence of green manufacturing techniques offers a promising path to mitigate the environmental impact of this essential industrial material. Through innovative technologies, responsible sourcing, and a commitment to reducing emissions, the petroleum industry has the potential to align with global sustainability goals.

The shift to green delayed petroleum coke manufacturing is not just an environmental necessity; it is an opportunity for economic resilience and innovation in a changing world. Stakeholders across the industry must work together to embrace these changes, ensuring a balanced approach to meeting energy demands and protecting our planet for generations to come.

-

Low Nitrogen Graphitized Petroleum Coke | High Purity Recarburiser

NewsAug.16,2025

-

Premium First Bauxite Exporters & Suppliers Worldwide

NewsAug.15,2025

-

Tundish Dry Vibrator: Fast, Durable Refractory Linings

NewsAug.14,2025

-

Premium Low Nitrogen Recarburiser | Graphitized Petroleum Coke

NewsAug.13,2025

-

Quality Building Material for Round Walls | Global Exporters

NewsAug.12,2025

-

First Bauxite Exporters: Global Manufacturer & Supplier

NewsAug.11,2025