Nov . 14, 2024 07:11 Back to list

sulfur adsorbent for h2s

Sulfur Adsorbents for H₂S Removal A Comprehensive Overview

Hydrogen sulfide (H₂S) is a colorless gas known for its characteristic foul odor reminiscent of rotten eggs. It is not only a nuisance but also poses significant health risks and environmental challenges, particularly in industrial settings such as petroleum refining, natural gas processing, and wastewater treatment. Consequently, the need for effective removal technologies for H₂S has garnered substantial attention within both scientific and industrial communities. Among various strategies, the use of sulfur adsorbents has emerged as a prominent solution due to their efficiency, cost-effectiveness, and sustainability.

Understanding H₂S Sources and Risks

H₂S is predominantly generated from natural sources, such as volcanic eruptions and decaying organic matter, but significant anthropogenic contributions arise from industrial processes. Exposure to H₂S can lead to serious health issues, including respiratory distress and neurological damage. At high concentrations, it can be lethal. Thus, regulatory bodies have established strict limits for H₂S emissions, compelling industries to invest in effective removal technologies.

Principles of Sulfur Adsorption

Sulfur adsorbents operate based on an adsorption process wherein H₂S molecules are captured on the surface of the adsorbent material. This method is beneficial because it allows for a relatively simple system design, often avoiding complex chemical reactions. The efficiency of sulfur adsorbents can be influenced by various factors, including temperature, pressure, and the specific surface area of the material.

Adsorbents can be categorized into physical and chemical adsorbents. Physical adsorbents rely on van der Waals forces, while chemical adsorbents engage in chemical reactions with H₂S to form stable compounds. The latter generally provides higher removal efficiencies and lower breakthrough times.

Types of Sulfur Adsorbents

The development of effective sulfur adsorbents has led to various innovative materials being employed in industries. Some of the most common sulfur adsorbents include

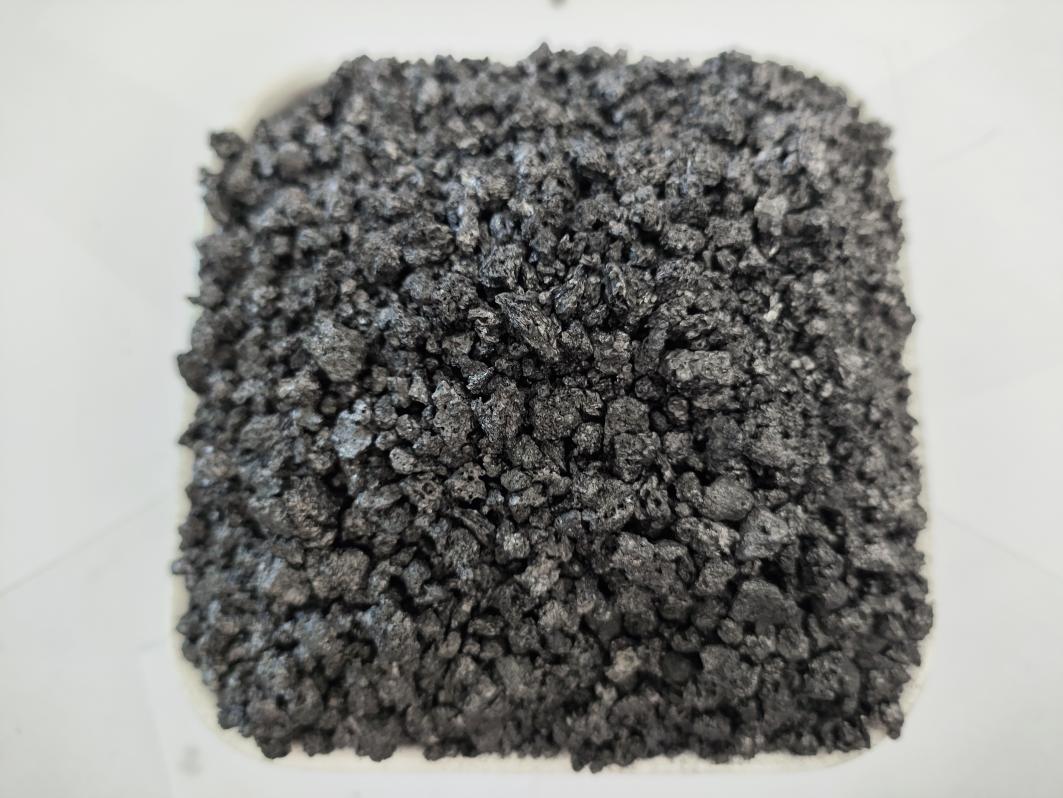

1. Activated Carbon Its extensive surface area and porous structure make activated carbon a popular choice for the adsorption of H₂S. It can also be modified with various functional groups to enhance its capacity for H₂S uptake.

sulfur adsorbent for h2s

2. Metal-Organic Frameworks (MOFs) These materials consist of metal ions coordinated to organic ligands, forming porous frameworks. MOFs have garnered attention due to their tunable pore sizes and high surface areas, which facilitate H₂S removal.

3. Zeolites Naturally occurring or synthetic zeolites are utilized for gas separation processes. Their crystalline structures allow for selective adsorption of H₂S, making them effective in various applications.

4. Sulfur-Impregnated Materials By introducing sulfur compounds into a matrix of other sorbents, these materials can significantly increase their H₂S adsorption capacity. This method combines the benefits of dual functionalities for enhanced performance.

Advantages of Using Sulfur Adsorbents

Opting for sulfur adsorbents in H₂S removal comes with numerous advantages. This method often operates under ambient conditions, requiring less energy than thermal or catalytic methods. The relatively simple design of adsorption systems also translates into lower capital and operational costs, making them attractive for large-scale industrial applications.

Furthermore, the regeneration of sulfur adsorbents can be feasibly achieved, allowing for the recovery of the adsorbent material and reducing waste generation. This aligns with growing sustainability efforts in industries aiming to minimize their environmental footprint.

Future Perspectives

The research and development of sulfur adsorbents remain a dynamic field. Innovations in material science, including the synthesis of new nanostructured adsorbents and hybrid systems combining various removal technologies, promise to enhance the efficiency and selectivity of H₂S removal processes. As industries continue to face challenges related to pollution control and regulatory compliance, the role of sulfur adsorbents will likely expand, contributing to safer and cleaner industrial practices.

In conclusion, sulfur adsorbents provide a pivotal technology in the quest for effective H₂S removal. With continued research and development, these technologies hold the potential to transform the landscape of gas treatment solutions, fostering a cleaner and more sustainable industrial environment.

-

High-Quality Fe-C Alloy Leading Manufacturers & Spherical Alloy Materials Supplier

NewsJun.10,2025

-

Premium Low Nitrogen Recarburiser Supplier & Manufacturer – High Quality Exporters

NewsJun.10,2025

-

DT4 High-Quality Magnetic Materials Leading DT4 Manufacturer & Supplier

NewsJun.10,2025

-

High-Performance Spring Steel Suppliers Custom Solutions

NewsJun.10,2025

-

Premium SWRCH6A Manufacturer Steel Wire Supplier & Factory

NewsJun.10,2025

-

Premium Mild Steel Wire Rod Supplier & Manufacturer

NewsJun.10,2025