Oct . 21, 2024 19:10 Back to list

Top Manufacturers of Steel and Graphite Products for Industrial Applications

Steel and Graphite Manufacturers A Synergistic Evolution

The intersection of steel and graphite manufacturing is a fascinating area in the industrial landscape that has significantly enhanced the efficiency and quality of various products. Both materials, while distinct in their properties and applications, share a mutual reliance in certain sectors, marking a robust synergy between the two manufacturing disciplines. This article will explore the roles of steel and graphite manufacturers, the advantages of their integration, and the future trends anticipated in the industry.

Understanding the Materials

Steel, an alloy of iron, is renowned for its strength, durability, and versatility, making it an indispensable material in construction, automotive, aerospace, and many other industries. It is known for its ability to withstand heavy loads, resist corrosion, and maintain structural integrity under extreme conditions. On the other hand, graphite, a form of carbon, is distinctively known for its excellent conductivity, lubricating properties, and thermal resistance. Its uses range from batteries and lubricants to advanced materials in aerospace and nuclear applications.

The Role of Manufacturers

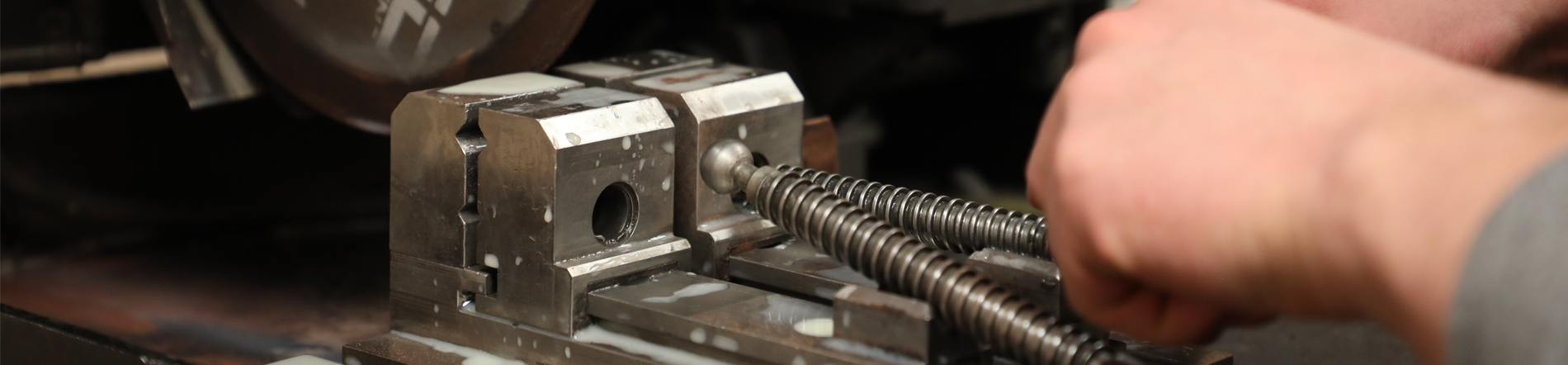

Manufacturers in the steel sector typically focus on the production and processing of various types of steel products, including sheets, bars, rods, and specialized alloys. They operate large-scale mills equipped with advanced technologies for smelting, rolling, and finishing processes. On the other end, graphite manufacturers utilize high-purity carbon and synthetic materials to produce graphite products like electrodes, lubricants, and composites. Both sectors are heavily influenced by technological advancements, consumer demand, and market fluctuations, necessitating a keen adaptability to remain competitive.

Integration and Synergy

The integration of steel and graphite manufacturing is best illustrated in the production of components such as electrodes used in electric arc furnaces (EAF) for steel production. Graphite electrodes are crucial for melting steel scrap in EAFs, a method that has gained popularity due to its energy efficiency and lower carbon footprint. The collaboration between these two sectors not only streamlines supply chains but also results in cost savings and improved product performance.

steel graphite manufacturers

Moreover, the use of graphite-based materials enhances the performance of steel in several applications. For instance, adding graphite to certain steel compositions can improve its thermal resistance and lubricity, making it suitable for high-stress applications like automotive parts and industrial machinery. As technological advancements continue to progress—for instance, in the realm of nano-materials—this synergy is expected to deepen, paving the way for innovative new products.

Challenges and Opportunities

Despite the promising collaboration, steel and graphite manufacturers face challenges that require strategic navigation. Fluctuating raw material prices, environmental regulations, and competition from alternative materials are significant dilemmas. Additionally, the industry is under pressure to embrace sustainable practices, requiring manufacturers to invest in green technologies and methods to reduce carbon emissions.

However, these challenges also present opportunities for innovation. For instance, the development of eco-friendly graphite sourcing and steel recycling methods could not only enhance sustainability but also open new markets. Furthermore, advancing technologies such as 3D printing require adaptable manufacturing processes that combine both steel and graphite, cited as a potential area for growth.

Looking Ahead

As we move forward, the relationship between steel and graphite manufacturers is likely to evolve dramatically. With the increasing dependence on renewable energy and electric vehicles, the demand for lightweight yet durable materials will soar. Graphite’s role in battery production, particularly lithium-ion batteries, further underscores its importance in future technologies. Simultaneously, as industries become more interconnected, steel manufacturers will continue to seek innovative ways to incorporate graphite-enhanced materials to improve their product offerings.

In conclusion, the world of steel and graphite manufacturing is a remarkable interplay of two vital materials. Their synergistic relationship not only boosts efficiency in production but also fosters innovation, presenting unique opportunities for growth in various applications. As manufacturers continue to navigate challenges and seize opportunities, the future promises a horizon rich with advancements, setting the stage for a new era in industrial manufacturing.

-

SWRCH35K High-Quality Steel Wire Rods - Reliable Manufacturer & Supplier

NewsJun.24,2025

-

High-Quality Fe-C Alloy Leading Manufacturers & Spherical Alloy Materials Supplier

NewsJun.10,2025

-

Premium Low Nitrogen Recarburiser Supplier & Manufacturer – High Quality Exporters

NewsJun.10,2025

-

DT4 High-Quality Magnetic Materials Leading DT4 Manufacturer & Supplier

NewsJun.10,2025

-

High-Performance Spring Steel Suppliers Custom Solutions

NewsJun.10,2025

-

Premium SWRCH6A Manufacturer Steel Wire Supplier & Factory

NewsJun.10,2025