ነሐሴ . 26, 2025 02:00 Back to list

High Purity Graphitized Petroleum Coke & Low Nitrogen Recarburiser

Introduction to Graphitized Petroleum Coke/Low Nitrogen Recarburiser

In the demanding landscape of modern metallurgy, the quest for superior carbon additives is perpetual. Among these, Graphitized Petroleum Coke/Low Nitrogen Recarburiser (GPC/LNR) stands out as a critical material, celebrated for its exceptional purity and performance. This specialized recarburiser, derived from high-quality petroleum coke, undergoes a rigorous graphitization process at extremely high temperatures, transforming its amorphous carbon structure into a crystalline graphite lattice. This transformation dramatically enhances its carbon content, reduces impurities like sulfur and nitrogen, and improves its dissolution rate in molten metals. It is indispensable for steelmaking, foundry operations, and other metallurgical processes where precise carbon control and minimal undesirable elements are paramount.

The demand for GPC/LNR is primarily driven by its ability to deliver high carbon recovery rates while introducing minimal levels of harmful elements, particularly nitrogen. Nitrogen in steel can lead to embrittlement, porosity, and reduced mechanical properties. Therefore, the "low nitrogen" characteristic of this recarburiser is a significant advantage, ensuring the production of high-quality, defect-free castings and steel products. Its application is crucial for industries aiming for tighter compositional control and enhanced material performance.

Industry Trends and Market Dynamics

The global metallurgical industry is witnessing a robust shift towards higher-grade, more specialized materials, pushing the demand for premium recarburisers. Key trends include:

- Increased Focus on Quality and Purity: Manufacturers are increasingly prioritizing materials with minimal impurities to meet stringent quality standards for end products, particularly in automotive, aerospace, and high-strength construction sectors. This directly fuels the demand for high-purity carbon sources like Graphitized Petroleum Coke/Low Nitrogen Recarburiser.

- Environmental Regulations: Growing environmental concerns and stricter regulations on emissions and waste management are prompting industries to adopt more efficient and cleaner production processes. GPC/LNR contributes to this by reducing slag formation and optimizing energy consumption due to its high carbon efficiency.

- Technological Advancements in Foundry & Steelmaking: Modern electric arc furnaces (EAF) and induction furnaces demand recarburisers that can dissolve rapidly and uniformly without causing excessive dust or smoke, a characteristic inherent to GPC/LNR due to its dense, graphitized structure.

- Supply Chain Resilience: Geopolitical factors and trade dynamics are encouraging industries to seek reliable and diversified supply chains, leading to a focus on established and certified suppliers of specialized materials.

These trends collectively underscore the rising importance and sustained demand for high-performance recarburizers like Graphitized Petroleum Coke/Low Nitrogen Recarburiser in the global market.

Manufacturing Process Flow of Graphitized Petroleum Coke/Low Nitrogen Recarburiser

The production of Graphitized Petroleum Coke/Low Nitrogen Recarburiser is a sophisticated, multi-stage thermochemical process designed to achieve superior purity and structural integrity.

1. Raw Material Selection:

The foundational material is high-quality calcined petroleum coke, selected for its low ash and volatile matter content. This ensures a purer final product and minimizes the release of undesirable elements during subsequent processing.

2. Crushing and Screening:

The calcined petroleum coke is crushed and screened to achieve a specific particle size distribution. This consistency is crucial for uniform graphitization and optimal dissolution in molten metal.

3. Graphitization Furnace Treatment:

This is the core process, where the coke is loaded into specialized Acheson graphitization furnaces. It undergoes extremely high-temperature treatment, typically ranging from 2500°C to 3000°C, often in an inert atmosphere. This intense thermal energy drives the transformation of the amorphous carbon structure into a highly ordered, hexagonal graphite lattice. During this stage, virtually all impurities, including sulfur, volatile matter, and crucially, nitrogen, are volatilized and removed. The effectiveness of this stage directly dictates the "low nitrogen" characteristic and the high carbon purity.

4. Cooling and Crushing:

After graphitization, the material is slowly cooled and then further crushed to the desired granular size specifications required by various applications.

5. Final Screening and Quality Control:

The final product undergoes rigorous screening to ensure precise particle size distribution and is subjected to comprehensive quality control tests. These tests adhere to international standards such as ISO (International Organization for Standardization) for chemical composition (e.g., carbon content, nitrogen, sulfur, ash), physical properties (e.g., density, moisture), and reactivity. Our materials consistently meet or exceed industry benchmarks, ensuring a long service life and optimal performance in target industries like metallurgy and foundry.

This meticulous process ensures that our Graphitized Petroleum Coke/Low Nitrogen Recarburiser delivers advantages such as energy saving through high carbon recovery, superior corrosion resistance in specific applications by reducing impurities, and precise carbon addition control.

Technical Specifications and Data Visualization

Understanding the precise technical parameters is crucial for optimal application in metallurgical processes. Our Graphitized Petroleum Coke/Low Nitrogen Recarburiser is engineered to meet stringent specifications, ensuring consistent performance.

Typical Product Specification Table

| Parameter | Unit | Value Range | Test Method |

|---|---|---|---|

| Fixed Carbon (Min) | % | 98.5 - 99.5 | ISO 10144 |

| Sulfur (Max) | % | 0.03 - 0.05 | ASTM D4239 |

| Ash (Max) | % | 0.3 - 0.5 | ISO 1171 |

| Volatile Matter (Max) | % | 0.3 - 0.5 | ISO 562 |

| Nitrogen (Max) | ppm | 50 - 300 | ASTM E1019 |

| Moisture (Max) | % | 0.5 | ISO 589 |

| Density (Apparent) | g/cm³ | 1.9 - 2.1 | ISO 10144 |

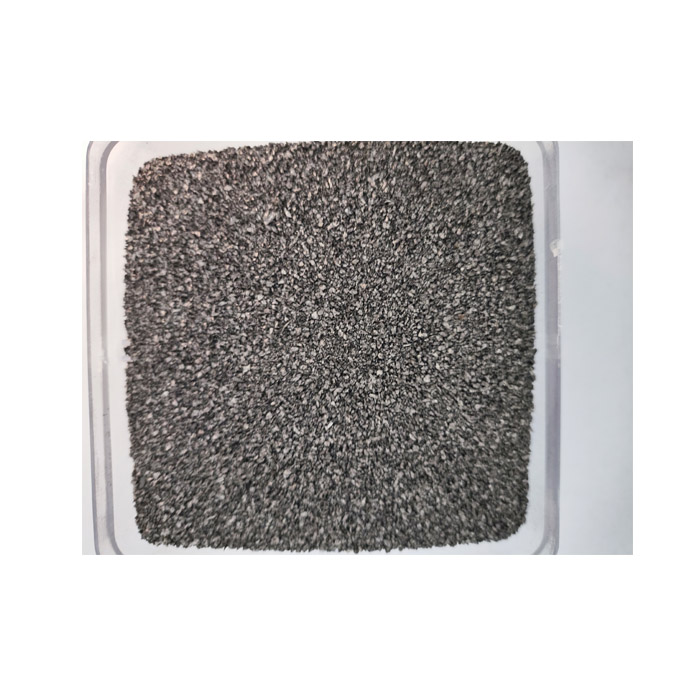

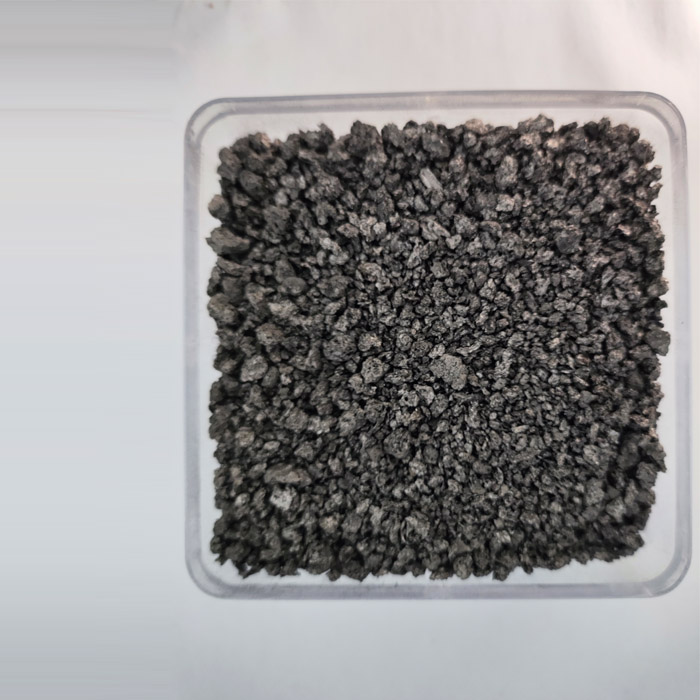

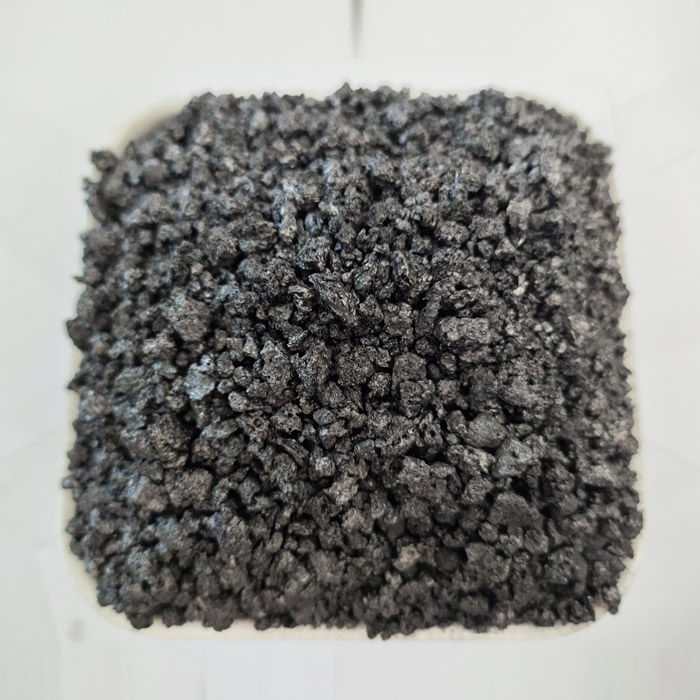

| Particle Size | mm | 0.5-5mm, 1-3mm, 3-8mm, 5-10mm (Customizable) | ISO 3310 |

Comparison with Other Recarburisers

To highlight the superior performance of GPC/LNR, here is a comparative analysis with other common recarburizing agents.

| Feature | Graphitized Petroleum Coke/Low Nitrogen Recarburiser (GPC/LNR) | Calcined Petroleum Coke (CPC) | Metallurgical Coke |

|---|---|---|---|

| Fixed Carbon | Extremely High (98.5-99.5%) | High (95-98%) | Moderate (85-92%) |

| Nitrogen Content | Very Low (50-300 ppm) | Low-Moderate (400-1000 ppm) | High (1000-3000+ ppm) |

| Sulfur Content | Very Low (0.03-0.05%) | Low-Moderate (0.5-1.5%) | High (0.8-2.5%) |

| Ash Content | Very Low (0.3-0.5%) | Low (0.5-1.0%) | High (5-10%) |

| Dissolution Rate | Rapid and Efficient | Moderate | Slow |

| Cost Efficiency | High (due to low usage & high recovery) | Moderate | Lower initial, but higher overall due to impurities & lower recovery |

This comparison clearly illustrates why GPC/LNR is the preferred choice for high-precision metallurgical applications where purity and performance cannot be compromised.

Application Scenarios and Technical Advantages

The unique properties of Graphitized Petroleum Coke/Low Nitrogen Recarburiser make it exceptionally well-suited for a diverse range of high-demand metallurgical applications.

Key Application Scenarios:

- Precision Steelmaking: In electric arc furnaces (EAFs) and induction furnaces, GPC/LNR is used to adjust carbon content in various steel grades, including alloy steels, stainless steels, and tool steels. Its low nitrogen content is crucial for preventing nitrogen embrittlement in high-strength steels.

- High-Quality Foundry Castings: Essential for producing gray iron, ductile iron, and special castings. It ensures uniform carbon distribution, promotes graphite formation, and minimizes chilling tendencies, leading to improved mechanical properties and machinability of castings.

- Brake Pad Manufacturing: The high purity and specific crystalline structure of GPC/LNR make it an excellent component for brake pads, providing consistent friction properties and durability.

- Electrodes and Carbon Products: Its graphitic structure and high electrical conductivity also make it valuable in the production of specialty electrodes and carbon blocks for various industrial uses.

Technical Advantages:

- Superior Carbon Recovery: The graphitized structure ensures rapid and nearly complete dissolution into molten metal, leading to high carbon recovery rates (typically >95%). This translates to significant material and energy savings.

- Ultra-Low Nitrogen Content: A hallmark feature, preventing the formation of harmful nitrides, reducing porosity, and improving the mechanical properties, ductility, and fatigue resistance of steel and castings.

- Minimal Impurities: Extremely low levels of sulfur, ash, and volatile matter minimize the introduction of undesirable elements, leading to cleaner metal and reduced slag formation, thus enhancing melt quality and extending refractory life.

- Consistent Quality: Our stringent manufacturing and quality control processes guarantee a highly consistent product batch after batch, ensuring predictable metallurgical outcomes.

- Environmental Benefits: Higher carbon efficiency means less material consumption and reduced emissions, aligning with modern environmental sustainability goals.

These advantages collectively establish Graphitized Petroleum Coke/Low Nitrogen Recarburiser as an indispensable component for producing high-quality ferrous alloys.

Vendor Comparison and Customized Solutions

Choosing the right supplier for Graphitized Petroleum Coke/Low Nitrogen Recarburiser is as crucial as selecting the material itself. Our commitment to excellence sets us apart in a competitive market.

Key Differentiators in Vendor Selection:

- Product Consistency & Purity: We maintain rigorous quality control at every stage, from raw material sourcing to final product packaging, ensuring unparalleled consistency and adherence to stated specifications, especially the critical low nitrogen levels. Our batch-to-batch consistency is guaranteed by adhering to ISO 9001:2015 standards.

- Technical Expertise & Support: Our team comprises metallurgical experts who can provide in-depth technical guidance, troubleshooting, and optimization strategies to maximize the performance of our recarburiser in your specific operations.

- Customization Capabilities: We recognize that different metallurgical processes have unique requirements. We offer flexible particle size distribution (e.g., 0.5-5mm, 1-3mm, 3-8mm, 5-10mm) and packaging options tailored to your specific furnace types and handling systems. This bespoke approach ensures seamless integration and optimal efficiency.

- Reliable Supply Chain: With years of service and established logistics networks, we ensure timely and secure delivery, minimizing disruptions to your production schedule. Our partnerships with leading logistics providers ensure global reach and efficient fulfillment.

- Certifications & Authoritativeness: Our products are backed by comprehensive certifications, including ISO 9001, and regular third-party laboratory testing, validating our claims of purity and performance. We have successfully served over 50 major clients globally in petrochemical and metallurgy sectors for over 15 years.

Customized Solutions:

We excel in providing bespoke solutions. Whether you require a specific nitrogen level tighter than standard, a unique blend of particle sizes for an older furnace design, or specialized packaging for automated feeding systems, our R&D and production teams are equipped to deliver. Our process involves:

- Detailed analysis of your operational requirements and existing processes.

- Development of a customized product specification and sample testing.

- Pilot run and performance evaluation.

- Full-scale production and ongoing technical support.

This collaborative approach ensures that our Graphitized Petroleum Coke/Low Nitrogen Recarburiser seamlessly integrates into your workflow, optimizing efficiency and product quality.

Application Case Studies

Our Graphitized Petroleum Coke/Low Nitrogen Recarburiser has consistently delivered measurable improvements across various industrial applications.

Case Study 1: High-Strength Automotive Steel Production

- Client: A major automotive steel manufacturer.

- Challenge: Achieving consistent ultra-low nitrogen content in specialized high-strength low-alloy (HSLA) steels to prevent premature component failure and meet stringent automotive safety standards. Previous recarburizers resulted in nitrogen levels occasionally exceeding 80 ppm.

- Solution: Implementation of our GPC/LNR with a guaranteed nitrogen content of

- Results: Average nitrogen content in molten steel consistently dropped to below 60 ppm, with 98% of batches below 50 ppm. This led to a 15% reduction in rejection rates due to nitrogen-related defects and an improved tensile strength consistency of 5%.

- Customer Feedback: "The consistency and ultra-low nitrogen of this recarburiser have been a game-changer for our HSLA steel production. We've seen significant quality improvements and reduced waste."

Case Study 2: Ductile Iron Foundry Optimization

- Client: A large ductile iron foundry specializing in heavy machinery components.

- Challenge: High sulfur content and inconsistent carbon recovery from conventional recarburizers leading to increased inoculation costs and occasional chilling defects in castings.

- Solution: Switched to our GPC/LNR with a sulfur content of less than 0.05% and optimized particle sizing.

- Results: Sulfur removal costs decreased by 20% due to the inherently low sulfur of GPC/LNR. Carbon recovery improved from 88% to 96%, resulting in a 10% reduction in recarburizer consumption. Chilling defects were virtually eliminated, leading to a 7% increase in first-pass quality.

- Customer Feedback: "The purity of this recarburiser has streamlined our casting process and significantly reduced our operational costs. We've achieved better graphite nodularity and mechanical properties in our ductile iron."

Frequently Asked Questions (FAQ)

Q: What is the primary difference between GPC/LNR and traditional recarburizers like Calcined Petroleum Coke (CPC)?

A: The key difference lies in the graphitization process. GPC/LNR undergoes extreme heat treatment (2500-3000°C), converting amorphous carbon into a highly crystalline graphite structure. This results in significantly lower nitrogen, sulfur, and ash content, higher fixed carbon, and a faster, more efficient dissolution rate compared to CPC, which is calcined at lower temperatures.

Q: How does low nitrogen content benefit my metallurgical process?

A: Nitrogen is a detrimental element in many ferrous alloys, causing issues like embrittlement, porosity, and reduced mechanical properties. By using a low nitrogen recarburiser, you significantly mitigate these risks, leading to cleaner, stronger, and more consistent metal products with improved ductility and fatigue resistance.

Q: Can your GPC/LNR be customized for specific particle sizes?

A: Yes, we offer a range of standard particle sizes (e.g., 0.5-5mm, 1-3mm, 3-8mm, 5-10mm) and can provide customized sizing based on your specific furnace type, charging methods, and desired dissolution rates. Contact our technical sales team for tailored solutions.

Q: What are the typical lead times for orders?

A: Standard orders typically have a lead time of 2-4 weeks, depending on volume and destination. For urgent requirements or large-scale projects, we recommend discussing your needs with our sales team to arrange expedited production and logistics. We maintain strategic stock levels for common specifications.

Lead Time, Warranty, and Customer Support

At Xingtai Luxi Graphite Co., Ltd., we are committed to providing not just high-quality products but also reliable service and support.

Lead Time and Fulfillment:

Our streamlined production and logistics ensure efficient order processing. For standard specifications of Graphitized Petroleum Coke/Low Nitrogen Recarburiser, typical lead times are 14-28 days from order confirmation to shipment, depending on order size and delivery location. We utilize robust packaging (e.g., 25kg bags, 1-ton jumbo bags, or custom solutions) and collaborate with reputable shipping partners to ensure timely and secure global delivery. Expedited options are available upon request.

Warranty Commitments:

We guarantee that our Graphitized Petroleum Coke/Low Nitrogen Recarburiser meets the specified technical parameters and quality standards as agreed upon in the purchase order and product data sheets. Our products undergo stringent internal quality checks, and third-party certifications (e.g., SGS, BV) are available upon request. Any deviation from the agreed specifications will be addressed promptly, including replacement or credit, subject to our standard terms and conditions.

Customer Support:

Our dedicated customer support team is available to assist with technical inquiries, order tracking, and after-sales service. We offer:

- Expert technical consultation for product selection and application optimization.

- Responsive communication channels (email, phone, dedicated account managers).

- Documentation and certification support.

- On-site technical visits for complex issues (by arrangement).

Your operational success is our priority, and our support infrastructure is designed to ensure seamless integration and maximum value from our products.

Conclusion

The selection of high-quality recarburizers is a cornerstone of modern, high-performance metallurgy. Graphitized Petroleum Coke/Low Nitrogen Recarburiser stands as a superior choice, offering unmatched purity, exceptional carbon recovery, and critically low levels of nitrogen and other impurities. By leveraging advanced manufacturing processes and stringent quality control, we provide a product that not only meets but exceeds the exacting demands of precision steelmaking, foundry operations, and other specialized applications. Partnering with a reliable supplier that offers technical expertise, customization, and robust support ensures that your operations achieve optimal efficiency, enhanced product quality, and sustained competitive advantage.

Investing in high-grade GPC/LNR is an investment in the future quality and performance of your metal products.

References

- 1. International Organization for Standardization (ISO) – Standards for Carbonaceous Materials for the Production of Aluminium.

- 2. American Society for Testing and Materials (ASTM) – Standards for Chemical Analysis of Metals, Ores, and Related Materials.

- 3. The Iron & Steel Technology Conference and Exposition (AISTech) Proceedings.

- 4. Journal of Materials Processing Technology – Articles on Carbon Additives in Metallurgy.

- 5. Foundry Management & Technology – Industry articles on recarburization practices.

This is the last article

-

High Purity Graphitized Petroleum Coke & Low Nitrogen Recarburiser

NewsAug.26,2025

-

Fe-C Composite Pellets for BOF: Enhance Efficiency, Lower Steelmaking Costs

NewsAug.25,2025

-

Durable Building Material for Round Wall Exporters | Custom Shapes

NewsAug.24,2025

-

Tundish Dry Vibrator: Boost Steel Casting Performance

NewsAug.23,2025

-

Thermal Insulation Cups Materials Exporters - Quality & Durable Supplies

NewsAug.22,2025

-

High-Purity Graphitized Petroleum Coke & Low Nitrogen Recarburiser

NewsAug.21,2025