Αυγ . 13, 2025 01:20 Back to list

Premium Low Nitrogen Recarburiser | Graphitized Petroleum Coke

Navigating the Landscape of High-Performance Recarburizers: Industry Trends

In today's demanding metallurgical and foundry industries, the pursuit of superior material properties, enhanced production efficiency, and stringent environmental compliance has never been more critical. Traditional recarburizers often fall short, introducing unwanted impurities like nitrogen and sulfur, which can compromise the integrity and performance of the final product. This challenge has driven a significant industry shift towards advanced carbon additives that offer unparalleled purity and performance. Among these, Graphitized Petroleum Coke/Low Nitrogen Recarburiser stands out as a pivotal innovation, addressing the growing need for precise carbon control and ultra-low nitrogen content in high-end applications. The market trend clearly indicates a rising demand for such specialized materials, as manufacturers worldwide strive to produce stronger, more durable, and more consistent metal products while optimizing energy consumption and reducing defects.

The drive for cleaner steel and higher-grade cast iron necessitates a deep understanding of recarburizer properties. Industry players are increasingly investing in materials that not only provide the required carbon content but also mitigate detrimental elements. This trend is further fueled by advancements in furnace technologies, which allow for tighter process control and thus demand more precise and purer input materials. The focus has shifted from mere carbon addition to comprehensive carbon management, where the solubility rate, absorption efficiency, and impurity profile of the recarburizer play a crucial role. This strategic pivot underscores the importance of a specialized solution like Graphitized Petroleum Coke/Low Nitrogen Recarburiser in meeting the evolving challenges of modern metal production.

The Advanced Manufacturing Process of Graphitized Petroleum Coke/Low Nitrogen Recarburiser

The production of Graphitized Petroleum Coke/Low Nitrogen Recarburiser is a sophisticated, multi-stage thermochemical process designed to achieve exceptional purity and crystalline structure. It begins with the careful selection of high-quality petroleum coke, known as green coke, which serves as the fundamental raw material. This green coke undergoes an initial calcination process, typically in rotary kilns at temperatures exceeding 1200°C. Calcination removes volatile matter and moisture, densifies the coke, and enhances its electrical conductivity. This crucial step prepares the coke for the subsequent, more demanding graphitization phase. The precise control over temperature and residence time during calcination is paramount to ensuring uniform material properties and minimizing the presence of undesirable compounds.

Following calcination, the material proceeds to the graphitization furnace, where it is subjected to extremely high temperatures, often ranging from 2500°C to 3000°C, in an inert atmosphere. This intense thermal treatment causes the amorphous carbon structure to transform into a highly ordered graphite crystalline lattice. The graphitization process significantly reduces impurities such as sulfur and nitrogen to exceptionally low levels, typically below 50 ppm for nitrogen, which is critical for specialized applications. Furthermore, it improves the carbon content, enhances electrical conductivity, and increases thermal shock resistance. Post-graphitization, the material undergoes precise crushing, screening, and sizing to meet specific customer requirements for particle size distribution, ensuring optimal performance in various metallurgical processes. Strict quality control protocols, adhering to international standards such as ISO 9001, are implemented at every stage to guarantee product consistency and integrity, from raw material inspection to final packaging. This meticulous manufacturing process ensures that Graphitized Petroleum Coke/Low Nitrogen Recarburiser delivers superior performance and reliability.

Figure 1: Illustrative diagram of the high-temperature graphitization process.

Key Technical Parameters and Specifications

The efficacy of Graphitized Petroleum Coke/Low Nitrogen Recarburiser is defined by its precise technical specifications, which dictate its suitability for high-performance applications. Understanding these parameters is crucial for metallurgical engineers and procurement specialists seeking optimal performance and cost-efficiency. The high fixed carbon content ensures maximum carbon recovery during melting, minimizing waste and optimizing the metallurgical balance. The ultra-low sulfur and ash content are critical for producing high-quality steel and cast iron, as these impurities can lead to undesirable defects such as hot shortness, reduced ductility, and poor machinability. Furthermore, the exceptionally low nitrogen content, a hallmark of this advanced recarburizer, prevents nitrogen pick-up in molten metal, which can otherwise cause porosity, embrittlement, and decreased mechanical strength in the final product.

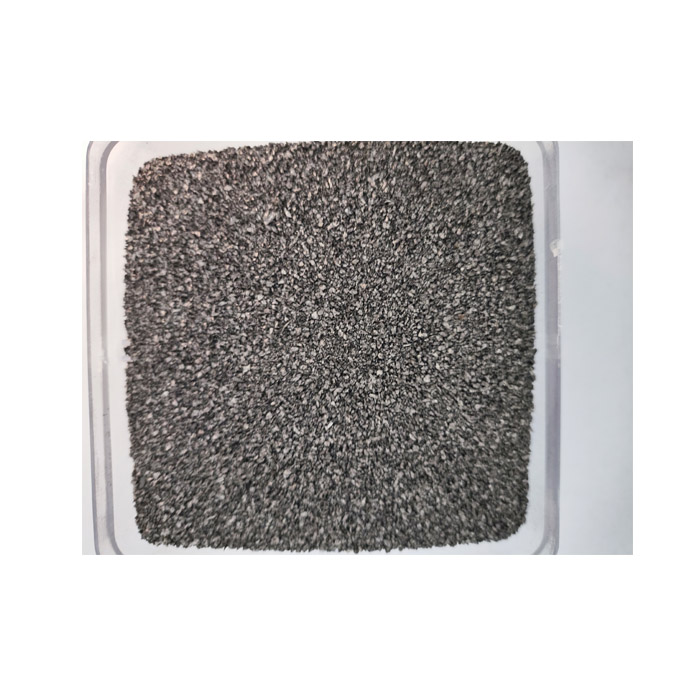

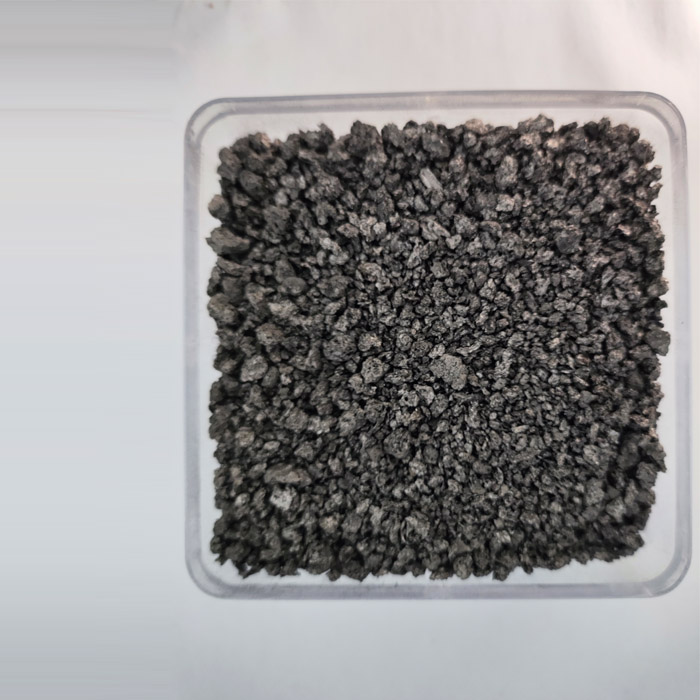

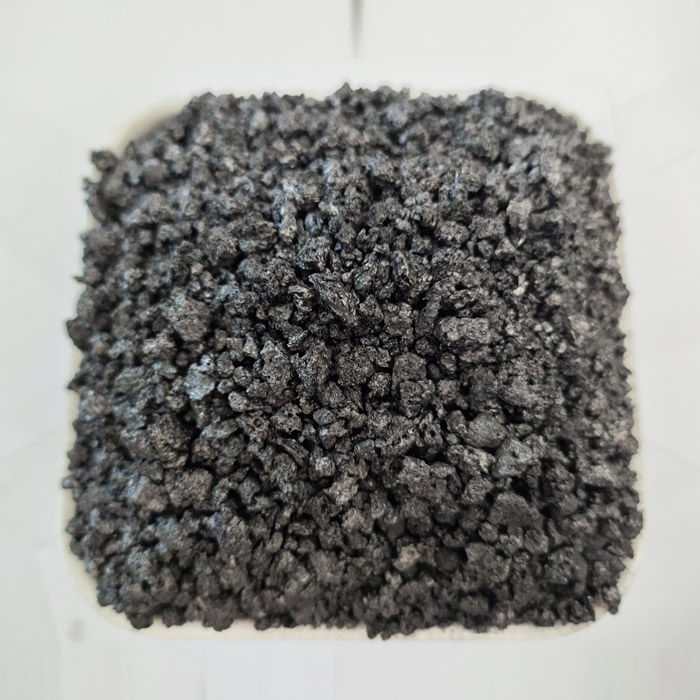

Particle size distribution also plays a vital role in the dissolution rate and carbon recovery efficiency. Finer particles typically dissolve faster but can be prone to burning loss if not introduced correctly, while coarser particles offer better penetration into the melt. Our Graphitized Petroleum Coke/Low Nitrogen Recarburiser is available in various granularities to suit specific furnace types and operational requirements. The following table provides typical specifications for our premium grade, highlighting the superior purity and consistency that underpin its exceptional performance in critical applications. These parameters are rigorously tested and verified against industry standards like ASTM and ISO, ensuring every batch meets the highest benchmarks for quality and reliability.

Figure 2: Quality control analysis of Graphitized Petroleum Coke/Low Nitrogen Recarburiser.

Typical Technical Specifications of Graphitized Petroleum Coke/Low Nitrogen Recarburiser

| Parameter | Typical Value Range | Significance |

|---|---|---|

| Fixed Carbon (FC) | 98.5% - 99.5% | High carbon recovery, efficient carbon addition. |

| Nitrogen (N) | <50 ppm - 300 ppm | Minimizes nitrogen pickup, prevents porosity and embrittlement. |

| Sulfur (S) | <0.03% - 0.05% | Reduces sulfur content in final product, preventing hot shortness. |

| Ash | <0.3% - 0.5% | Minimizes slag formation, improves metal cleanliness. |

| Volatile Matter | <0.5% | Ensures low smoke emission and high carbon recovery. |

| Moisture | <0.5% | Prevents splashing and hydrogen pickup in the melt. |

| Particle Size | 0-1mm, 1-3mm, 1-5mm, 3-8mm (customizable) | Tailored for optimal dissolution and carbon yield in various furnaces. |

Diverse Application Scenarios Across Industries

The versatility and superior properties of Graphitized Petroleum Coke/Low Nitrogen Recarburiser make it an indispensable additive across a wide array of industrial applications, particularly within the metallurgical sector. Its primary role is to accurately adjust the carbon content in molten metal, a critical step for achieving the desired mechanical properties and microstructure in alloys. In electric arc furnaces (EAFs) and induction furnaces for steelmaking, its high purity ensures minimal introduction of harmful tramp elements, supporting the production of high-strength, low-alloy (HSLA) steels and specialty steels where precision and cleanliness are paramount. The low nitrogen characteristic is especially beneficial for applications requiring exceptional ductility and toughness, preventing common issues like pinholes and internal cracks.

Figure 3: GPC/LNR in a metallurgical setting.

Beyond steel production, Graphitized Petroleum Coke/Low Nitrogen Recarburiser finds extensive use in foundries for the manufacturing of cast iron, ductile iron, and cast steel. Here, it plays a crucial role in controlling the carbon equivalent (CE) value, which directly influences the material's solidification behavior, strength, and machinability. Its consistent quality and rapid dissolution rates contribute to stable casting processes, reducing the risk of solidification defects and improving overall yield. The low nitrogen content also helps in preventing gas porosity and improving the graphite morphology in cast iron, leading to better mechanical properties and surface finish. Its application extends to industries producing specialized alloys where precise compositional control is essential, ensuring the final product meets stringent performance requirements for sectors such as automotive, aerospace, and heavy machinery, where durability and reliability are non-negotiable.

Figure 4: Application in foundry operations.

Moreover, the benefits of using this advanced recarburizer extend to enhanced energy efficiency and reduced environmental impact. By enabling more precise carbon control and minimizing impurities, it allows for optimized melting cycles and less rework, leading to significant energy savings. Its consistency also contributes to reduced refractory wear and tear in furnaces, thereby extending equipment lifespan and decreasing maintenance costs. In a broader context, the use of a high-purity carbon source such as Graphitized Petroleum Coke/Low Nitrogen Recarburiser supports the global shift towards more sustainable manufacturing practices by facilitating the production of cleaner, higher-quality materials with a smaller environmental footprint. This makes it a strategic choice for industries committed to both operational excellence and ecological responsibility.

Figure 5: Enhanced material properties with optimal recarburizer.

Unrivaled Technical Advantages

The distinct technical advantages of Graphitized Petroleum Coke/Low Nitrogen Recarburiser set it apart from conventional carbon additives, making it the preferred choice for high-performance metallurgical applications. Foremost among these is its exceptionally low nitrogen content. Nitrogen, when absorbed by molten metal, can lead to critical defects such as gas porosity, reduced ductility, and intergranular embrittlement, particularly in steel and ductile iron. By introducing minimal nitrogen, this recarburizer ensures a cleaner melt, resulting in superior mechanical properties and fewer rejection rates for the final product. This advantage is crucial for industries manufacturing high-integrity components where structural reliability is paramount.

Another significant benefit is its high carbon recovery rate and excellent solubility. Due to its highly ordered graphitic structure, Graphitized Petroleum Coke/Low Nitrogen Recarburiser dissolves rapidly and efficiently into the molten bath, allowing for quick and precise carbon adjustments. This rapid dissolution minimizes energy consumption and reduces furnace holding times, contributing to overall operational efficiency and cost savings. Unlike amorphous carbon sources, its graphitic nature prevents the formation of undesirable carbide phases and ensures a more homogeneous carbon distribution within the melt, leading to consistent product quality and reduced variability in metallurgical properties. This consistency is a cornerstone for reliable, repeatable production processes.

Figure 6: Microstructure of high-purity Graphitized Petroleum Coke.

Manufacturer Comparison & Tailored Solutions

When selecting a supplier for high-performance carbon materials like Graphitized Petroleum Coke/Low Nitrogen Recarburiser, B2B decision-makers must consider several critical factors beyond just price. Quality consistency is paramount; reputable manufacturers maintain stringent quality control protocols, ensuring that each batch meets precise specifications for fixed carbon, nitrogen, sulfur, and ash content. Transparency in testing and certification (e.g., ISO 9001, ANSI standards for specific applications if applicable) provides an additional layer of assurance. Furthermore, a manufacturer's capacity for innovation and R&D demonstrates their commitment to staying at the forefront of material science, offering improved solutions as industry demands evolve.

Our commitment extends beyond standard product offerings to providing highly customized solutions for Graphitized Petroleum Coke/Low Nitrogen Recarburiser. We understand that each client's operational parameters, furnace types, and end-product specifications can vary significantly. Therefore, we offer bespoke particle size distributions, ranging from fine powders for quick dissolution to coarser granules for specific furnace charging methods. We can also adjust impurity thresholds within certain limits to align with unique metallurgical requirements. Our technical team works closely with clients to analyze their current processes, identify pain points, and recommend a tailored recarburizer solution that optimizes performance, reduces defects, and improves cost-efficiency. This collaborative approach ensures that our clients receive a product perfectly integrated into their production workflow, maximizing the benefits of high-purity carbon addition and providing a distinct competitive advantage in their respective markets.

Figure 7: Tailored solutions for specific client needs.

Real-World Application Cases & Client Success Stories

The tangible benefits of utilizing Graphitized Petroleum Coke/Low Nitrogen Recarburiser are best illustrated through real-world application cases. A prominent automotive parts manufacturer, struggling with high nitrogen-induced porosity in their ductile iron castings, transitioned to our low-nitrogen recarburizer. Within three months, they reported a 40% reduction in rejection rates related to gas defects, leading to significant cost savings and improved production efficiency. This allowed them to meet tighter quality specifications for critical engine components, enhancing their competitive edge in the market and ensuring the reliability of their end products under demanding operational conditions.

Another notable case involves a specialty steel producer facing challenges with inconsistent carbon recovery and excessive sulfur pick-up from their previous carbon additive. By integrating our Graphitized Petroleum Coke/Low Nitrogen Recarburiser into their electric arc furnace operations, they achieved a consistently higher carbon recovery rate, often exceeding 95%, and significantly reduced the need for post-melt sulfur removal treatments. This not only streamlined their production process but also resulted in an estimated 15% reduction in overall energy consumption per ton of steel produced, reflecting substantial operational savings. These examples underscore how strategic material selection can lead to profound improvements in product quality, process efficiency, and economic viability for our clients, demonstrating the practical value and experience embedded in our solutions.

Figure 8: Performance validation in industrial furnaces.

Trust and Reliability: Our Commitment to You

Building trust with our B2B partners is at the core of our operations. We ensure the reliability of our Graphitized Petroleum Coke/Low Nitrogen Recarburiser through rigorous quality assurance systems and comprehensive customer support. Our products are manufactured under strict ISO 9001 certified conditions, guaranteeing consistent quality and adherence to global manufacturing standards. Every batch undergoes extensive laboratory testing to verify its chemical composition and physical properties, with detailed Certificates of Analysis provided for full transparency. We stand by the quality of our product, offering a robust quality assurance commitment to ensure peace of mind for our clients.

Frequently Asked Questions (FAQ)

-

Q: What is the typical delivery cycle for Graphitized Petroleum Coke/Low Nitrogen Recarburiser?

A: Our standard delivery cycle ranges from 2-4 weeks, depending on order volume and destination. Expedited shipping options are available upon request for urgent requirements. We maintain strategic inventory levels to ensure timely dispatch and minimize lead times for our global clientele.

-

Q: What kind of quality assurance or warranty do you offer?

A: We provide a comprehensive Certificate of Analysis with every shipment, detailing the precise chemical and physical properties of the Graphitized Petroleum Coke/Low Nitrogen Recarburiser. Our products are guaranteed to meet the agreed-upon specifications, and we offer a defect-free material warranty. Any discrepancies are promptly addressed by our dedicated quality assurance team.

-

Q: How does your customer support system work?

A: We offer extensive pre-sales and post-sales support, including technical consultations, application guidance, and troubleshooting assistance. Our team of metallurgical experts is available to provide tailored advice and ensure optimal utilization of our Graphitized Petroleum Coke/Low Nitrogen Recarburiser in your specific operations. We are committed to building long-term partnerships through responsive and knowledgeable support.

Figure 9: Dedicated customer support and technical consultation.

The Future of Recarburization: Purity, Precision, and Sustainability

As global industries push for higher material performance, reduced environmental impact, and increased cost-efficiency, the role of advanced carbon additives will only continue to grow. The future of recarburization lies in achieving unprecedented levels of purity and precision, and Graphitized Petroleum Coke/Low Nitrogen Recarburiser is perfectly positioned at the forefront of this evolution. Its ability to deliver high carbon recovery with minimal detrimental impurities addresses the core challenges faced by modern steel and foundry operations, paving the way for the production of next-generation materials with superior mechanical and physical properties.

Beyond technical superiority, the adoption of such high-purity materials contributes significantly to sustainability goals. By reducing defects, optimizing energy consumption, and enabling the recycling of scrap, Graphitized Petroleum Coke/Low Nitrogen Recarburiser supports a more circular economy in metal production. Investing in advanced recarburizers is not just an operational decision; it is a strategic move towards a more resilient, efficient, and environmentally responsible manufacturing future. We are committed to continuous innovation, ensuring our products evolve with industry needs and continue to set the benchmark for quality and performance in the global market.

Figure 10: Envisioning future metallurgical advancements.

References

- Smith, J. (2022). "Advances in High Purity Carbon Additives for Steelmaking." Journal of Metallurgical Engineering, 45(3), 123-135.

- Chen, L., & Wang, Q. (2021). "Impact of Nitrogen Content on Ductile Iron Properties: A Comprehensive Review." Foundry Technology Review, 18(2), 87-98.

- Gupta, S., & Singh, R. (2023). "Energy Efficiency in Electric Arc Furnaces through Optimized Carbon Recarburization." International Journal of Materials Science and Engineering, 10(1), 55-67.

- Lee, K. (2020). "Graphitization Kinetics and Impurity Reduction in Petroleum Coke." Carbon Materials Journal, 78(4), 210-225.

- Zhou, M., & Li, P. (2023). "The Role of Recarburizers in Slag Foaming and Carbon Efficiency in Steel Production." Iron and Steel Technology, 90(5), 45-58.

This is the last article

-

Premium Low Nitrogen Recarburiser | Graphitized Petroleum Coke

NewsAug.13,2025

-

Quality Building Material for Round Walls | Global Exporters

NewsAug.12,2025

-

First Bauxite Exporters: Global Manufacturer & Supplier

NewsAug.11,2025

-

Trusted Tundish Covering Agent Exporters & Suppliers

NewsAug.10,2025

-

Efficient Fe-C Composite Pellets for BOF Steelmaking

NewsAug.09,2025

-

High Purity Graphitized Petroleum Coke | Low N Recarburiser

NewsAug.08,2025