juuli . 28, 2025 17:09 Tagasi nimekirja

Strength with Premium Steel and Calcined Bauxite

In heavy-duty manufacturing and engineering applications, material selection plays a decisive role in operational efficiency, product lifespan, and overall structural integrity. For industries focused on durability, precision, and high-performance outcomes, selecting advanced materials like calcined bauxite, steel grade alloys, and high-strength steel types is no longer optional—it’s essential. These materials form the backbone of automotive, aerospace, energy, and tooling sectors, where failure is not an option and consistency is non-negotiable. The evolution of industrial design continues to push the demand for specialized steels and engineered minerals that support innovation under extreme conditions.

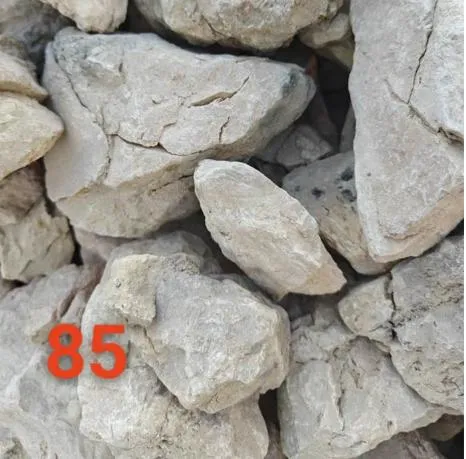

Integrating Calcined Bauxite into Industrial Abrasion-Resistant Systems

One of the most effective materials for wear resistance is calcined bauxite, widely used in anti-skid surfaces, refractory linings, and abrasive applications. The inclusion of calcined bauxite in industrial systems significantly enhances mechanical strength, hardness, and thermal resistance. It is particularly valued in metallurgical and ceramic applications due to its high aluminum content and low iron impurities. Whether used in blast furnace linings or high-friction flooring in steel mills, this mineral supports performance under high pressure and temperature, where other materials falter. Its reliability in supporting safety and operational continuity makes it indispensable across high-load environments.

Engineering Precision with Customized Steel Grade Alloys for Performance

Selecting the proper steel grade alloy ensures that industrial components perform at optimal capacity under mechanical stress. While general-purpose steel may suffice in low-demand scenarios, industries like automotive stamping, oil and gas drilling, and structural engineering require tailored steel grade formulations. These alloys are modified to offer enhanced tensile strength, corrosion resistance, or fatigue endurance, depending on their application. In heavy machinery production, for example, high-carbon tool steels are commonly selected for their edge retention and toughness. The right steel grade minimizes failure risks, extends machinery life, and guarantees compliance with global engineering standards.

Streamlining Cold Heading Processes with High-Ductility Cold Heading Steel

In manufacturing fasteners such as bolts, nuts, and screws, cold heading steel plays a critical role in forming without cracking. This specialized material is engineered for high ductility and formability, allowing it to be shaped at room temperature without compromising strength. The true value of cold heading steel is seen in mass-production settings where precision, consistency, and material economy are paramount. Its superior machinability and surface finish make it the go-to choice for automotive and aerospace fastener producers. Furthermore, cold heading reduces waste and energy consumption, aligning with sustainable industrial practices without sacrificing mechanical performance.

Maximizing Load-Bearing Capacity with Heat-Treated Bearing Steel

The success of rotating machinery heavily relies on the integrity of its components, and bearing steel remains the gold standard for such applications. Characterized by high hardness, excellent fatigue strength, and dimensional stability, bearing steel is essential in producing roller bearings, ball bearings, and other critical motion-control parts. This type of steel undergoes meticulous heat treatment processes to achieve a microstructure capable of withstanding extreme mechanical and thermal stress. In sectors such as mining, railway, and precision robotics, its use reduces friction and operational failures, extending service life and improving equipment reliability under constant dynamic load.

Elevating Durability with High-Tension Spring Steel for Mechanical Applications

From suspension systems to precision instruments, spring steel is integral where elasticity and toughness must coexist. Offering exceptional yield strength and fatigue resistance, spring steel maintains structural integrity even after repeated cycles of bending or twisting. Industrial designers rely on this material for producing washers, clamps, and resilient couplings. Its performance is essential in sectors such as rail transportation, wind energy, and agricultural machinery. The presence of alloying elements like silicon, chromium, or manganese in spring steel ensures optimal performance even in high-vibration or load-variable environments, where other materials would quickly degrade.

What Distinguishes Calcined Bauxite in Industrial Material Selection?

Calcined bauxite is highly sought after due to its superior hardness, thermal stability, and abrasion resistance, making it ideal for high-stress industrial environments where surface wear is a critical concern.

How Are Steel Grades Classified in Industrial Standards?

Steel grades are typically classified based on chemical composition and mechanical properties such as tensile strength, yield point, and elongation. International standards like AISI, DIN, and JIS provide detailed classification systems for engineering use.

What Makes Cold Heading Steel More Suitable for Fastener Production?

Cold heading steel is specifically processed to ensure uniform grain structure and high ductility, allowing it to withstand deformation without fracture during cold forming operations in fastener manufacturing.

How Does Bearing Steel Prevent Component Failure in Rotational Equipment?

Bearing steel undergoes a specialized heat treatment to achieve a hardened microstructure, reducing friction and preventing surface fatigue, thereby prolonging the service life of rotating components under dynamic loads.

In What Applications Is Spring Steel Preferred Over Other Alloy Types?

Spring steel is preferred in applications where components must endure high stress and deformation repeatedly, such as suspension coils, valve springs, and locking clips in automotive and industrial machinery.

Industrial Steel and Calcined Bauxite FAQs

Q: What is the typical use of calcined bauxite in steel manufacturing plants?

A: Calcined bauxite is primarily used for refractory linings in furnaces and ladles due to its high melting point and excellent thermal resistance.

Q: Which steel grade is most suitable for structural applications under high stress?

A: High-strength low-alloy (HSLA) steels or quenched and tempered alloy steels are often used for structural applications due to their superior tensile strength and toughness.

Q: How does cold heading steel contribute to cost-efficiency in fastener manufacturing?

A: Cold heading steel allows for high-speed manufacturing without requiring heat treatment during shaping, reducing energy consumption and production costs.

Q: What are the key characteristics of bearing steel?

A: Bearing steel offers high wear resistance, fatigue life, and dimensional stability under load, making it essential for components subjected to repeated motion.

Q: Can spring steel be customized for specific industrial needs?

A: Yes, the composition and heat treatment of spring steel can be tailored to meet specific stress tolerances, corrosion resistance, or elasticity requirements.

See on viimane artikkel

-

Strength with Premium Steel and Calcined Bauxite

UudisedJul.28,2025

-

Revolutionize Construction Efficiency with Smart Industrial Materials

UudisedJul.28,2025

-

Redefined with High-Grade Iron Powder Solutions

UudisedJul.28,2025

-

Metallurgical Efficiency with Innovative Recarburisers and Covering Agents

UudisedJul.28,2025

-

Industrial Efficiency Enhanced with High-Performance Recarburizer Solutions

UudisedJul.28,2025

-

Boosted by Advanced Iron Powder and Carbon Additive Solutions

UudisedJul.28,2025