Feb . 14, 2025 18:20 Back to list

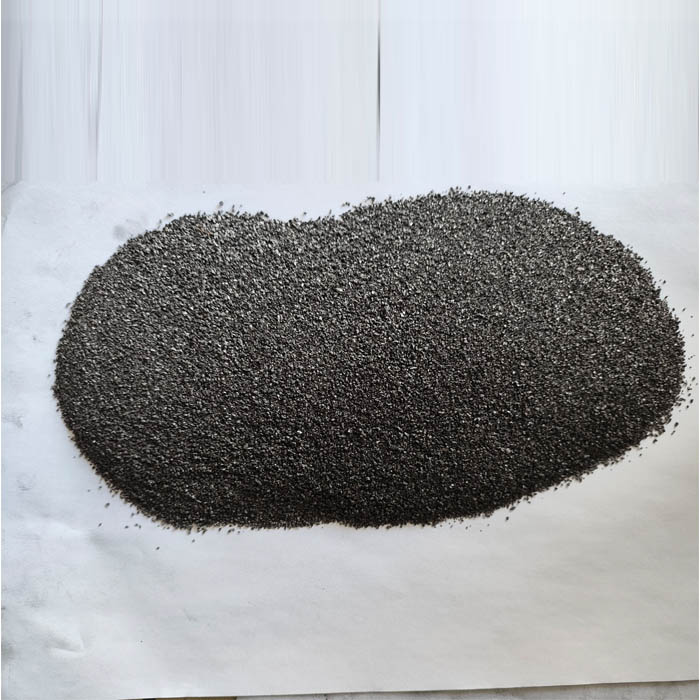

Tundish Dry Vibration Material

Choosing the right pipe insulation cover material is crucial for both residential and industrial applications. With an array of options available, it becomes imperative to understand the nuances of each material in order to make informed decisions that align with specific needs.

On the industrial front, cellular glass insulation offers unmatched durability and fire resistance. This rigid material excels in extreme temperature conditions, providing excellent protection against both thermal shock and fire hazards. Its closed-cell structure ensures zero permeability to moisture, making it an authoritative choice for offshore and chemical processing industries. Cellular glass’s ability to withstand harsh environments without degradation further enhances its trustworthiness among professionals. Polyethylene is another emerging material in the insulation cover market, celebrated for its anti-microbial properties and resistance to chemicals. Ideal for use in pharmaceutical and food processing industries, polyethylene covers ensure hygienic insulation with minimal maintenance. As sustainability becomes increasingly important, polyethylene’s recyclable nature enhances its appeal as a credible option for eco-conscious projects. Material selection isn’t just about performance metrics. Regulatory compliance is critical, and understanding the fire ratings and certifications of each insulation cover material is essential for ensuring safety and adherence to standards. Materials with documented compliance with ASTM International standards or those carrying reliable certifications often provide peace of mind and add a layer of trustworthiness to the choices made. Practical installation and maintenance considerations also play a significant role in selecting the right insulation cover material. Materials like foam rubber and polyethylene, known for their lightweight and flexible properties, simplify installation and reduce labor costs. Conversely, more rigid options like cellular glass might require specialized procedures and consideration during installation, impacting project timelines and budgets. In summary, selecting the appropriate pipe insulation cover material is an intricate process that balances performance, compliance, installation, and sustainability. Decades of experience underscore fiberglass and foam rubber as versatile and efficient choices for diverse environments. Meanwhile, reflective, cellular glass, and polyethylene materials represent innovative solutions engineered to meet specialized needs. Trustworthy performance, combined with responsible selection and expert application, ensures lasting benefits and optimized operational efficiency. The array of choices affords decision-makers the ability to tailor solutions that are as unique as the pipes they aim to protect.

On the industrial front, cellular glass insulation offers unmatched durability and fire resistance. This rigid material excels in extreme temperature conditions, providing excellent protection against both thermal shock and fire hazards. Its closed-cell structure ensures zero permeability to moisture, making it an authoritative choice for offshore and chemical processing industries. Cellular glass’s ability to withstand harsh environments without degradation further enhances its trustworthiness among professionals. Polyethylene is another emerging material in the insulation cover market, celebrated for its anti-microbial properties and resistance to chemicals. Ideal for use in pharmaceutical and food processing industries, polyethylene covers ensure hygienic insulation with minimal maintenance. As sustainability becomes increasingly important, polyethylene’s recyclable nature enhances its appeal as a credible option for eco-conscious projects. Material selection isn’t just about performance metrics. Regulatory compliance is critical, and understanding the fire ratings and certifications of each insulation cover material is essential for ensuring safety and adherence to standards. Materials with documented compliance with ASTM International standards or those carrying reliable certifications often provide peace of mind and add a layer of trustworthiness to the choices made. Practical installation and maintenance considerations also play a significant role in selecting the right insulation cover material. Materials like foam rubber and polyethylene, known for their lightweight and flexible properties, simplify installation and reduce labor costs. Conversely, more rigid options like cellular glass might require specialized procedures and consideration during installation, impacting project timelines and budgets. In summary, selecting the appropriate pipe insulation cover material is an intricate process that balances performance, compliance, installation, and sustainability. Decades of experience underscore fiberglass and foam rubber as versatile and efficient choices for diverse environments. Meanwhile, reflective, cellular glass, and polyethylene materials represent innovative solutions engineered to meet specialized needs. Trustworthy performance, combined with responsible selection and expert application, ensures lasting benefits and optimized operational efficiency. The array of choices affords decision-makers the ability to tailor solutions that are as unique as the pipes they aim to protect.

Latest news

-

High-Purity Graphitized Petroleum Coke & Low Nitrogen Recarburiser

NewsAug.21,2025

-

High-Performance Fe-C Composite Pellets for BOF

NewsAug.19,2025

-

Tundish Dry Vibrator: Enhance Refractory Life & Casting Efficiency

NewsAug.18,2025

-

Building Material for Round Wall Exporters: Quality & Durable

NewsAug.17,2025

-

Low Nitrogen Graphitized Petroleum Coke | High Purity Recarburiser

NewsAug.16,2025

-

Premium First Bauxite Exporters & Suppliers Worldwide

NewsAug.15,2025