febr . 19, 2025 00:46 Back to list

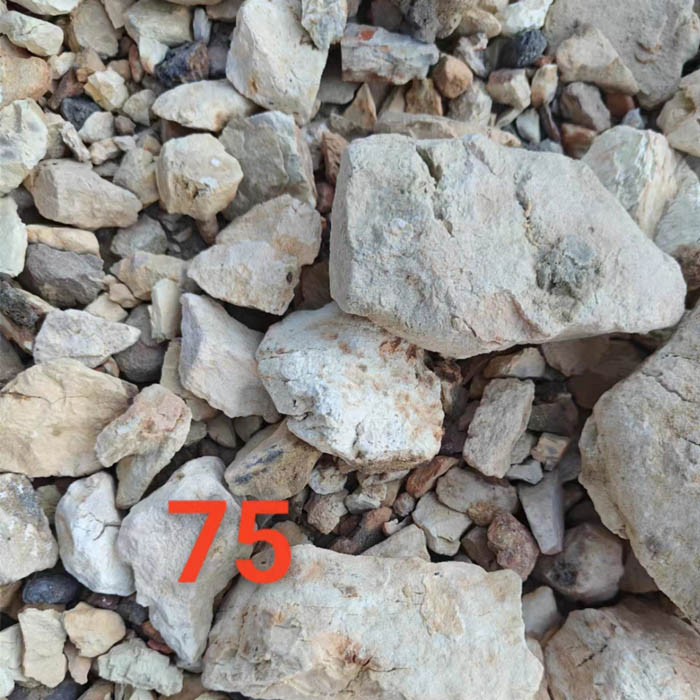

tundish covering agent

Tundish covering agents play a crucial role in the continuous casting process of steel manufacturing, acting as a protective layer that enhances the efficiency and quality of the process. Over the recent decades, significant advancements have been made in the formulation and application of these agents, making it imperative for industry professionals to stay current with the latest developments.

Manufacturers are increasingly prioritizing sustainability, which has influenced the development of tundish covering agents. The latest products are formulated to reduce emissions and are often made from recyclable materials. This shift not only helps in reducing the carbon footprint of steel production but also provides compliance with stricter environmental regulations and standards. One real-life example of effective tundish covering agent application can be seen in a prominent European steel producer company. By switching to a high-performance agent optimized for their process, they achieved a remarkable 10% reduction in energy consumption, alongside enhanced steel cleanliness. This transition underscores the transformative impact of using the right tundish covering agent, leading to cost savings and improved product quality. Despite these advancements, there remain challenges in the consistent application of tundish covering agents. Uniform coverage is critical to their effectiveness. Innovative application techniques, such as automated dispensing systems, have been developed to address this issue, ensuring consistent application and coverage across the tundish surface. When considering a tundish covering agent, trust in the product’s performance should be backed by a record of thorough testing and industry certifications. Reputable suppliers will provide detailed technical data sheets and case studies demonstrating their product's efficacy and compliance with industry standards. In summary, tundish covering agents are an indispensable component of the continuous casting process, directly influencing the efficiency and output quality of steel production. Leveraging the expertise of industry professionals and embracing novel product formulations can lead to improved operational performance and environmental sustainability. As the metallurgical industry continues to evolve, staying informed of advancements in tundish covering agent technology will play a critical role in maintaining competitiveness and achieving operational excellence.

Manufacturers are increasingly prioritizing sustainability, which has influenced the development of tundish covering agents. The latest products are formulated to reduce emissions and are often made from recyclable materials. This shift not only helps in reducing the carbon footprint of steel production but also provides compliance with stricter environmental regulations and standards. One real-life example of effective tundish covering agent application can be seen in a prominent European steel producer company. By switching to a high-performance agent optimized for their process, they achieved a remarkable 10% reduction in energy consumption, alongside enhanced steel cleanliness. This transition underscores the transformative impact of using the right tundish covering agent, leading to cost savings and improved product quality. Despite these advancements, there remain challenges in the consistent application of tundish covering agents. Uniform coverage is critical to their effectiveness. Innovative application techniques, such as automated dispensing systems, have been developed to address this issue, ensuring consistent application and coverage across the tundish surface. When considering a tundish covering agent, trust in the product’s performance should be backed by a record of thorough testing and industry certifications. Reputable suppliers will provide detailed technical data sheets and case studies demonstrating their product's efficacy and compliance with industry standards. In summary, tundish covering agents are an indispensable component of the continuous casting process, directly influencing the efficiency and output quality of steel production. Leveraging the expertise of industry professionals and embracing novel product formulations can lead to improved operational performance and environmental sustainability. As the metallurgical industry continues to evolve, staying informed of advancements in tundish covering agent technology will play a critical role in maintaining competitiveness and achieving operational excellence.

Next:

Latest news

-

High-Performance Fe-C Composite Pellets for BOF

NewsAug.19,2025

-

Tundish Dry Vibrator: Enhance Refractory Life & Casting Efficiency

NewsAug.18,2025

-

Building Material for Round Wall Exporters: Quality & Durable

NewsAug.17,2025

-

Low Nitrogen Graphitized Petroleum Coke | High Purity Recarburiser

NewsAug.16,2025

-

Premium First Bauxite Exporters & Suppliers Worldwide

NewsAug.15,2025

-

Tundish Dry Vibrator: Fast, Durable Refractory Linings

NewsAug.14,2025