ឧសភា . 13, 2025 10:24 Back to list

35CrMoA Alloy Steel Supplier High-Strength Manufacturer & Factory

- Introduction to 35crmoa

and Its Industrial Significance - Technical Advantages of 35crmoa Material

- Comparative Analysis of Leading 35crmoa Manufacturers

- Custom Solutions for 35crmoa Applications

- Case Studies: 35crmoa in High-Stress Environments

- Quality Assurance and Certification Standards

- Future Trends in 35crmoa Manufacturing

(35crmoa)

Introduction to 35crmoa and Its Industrial Significance

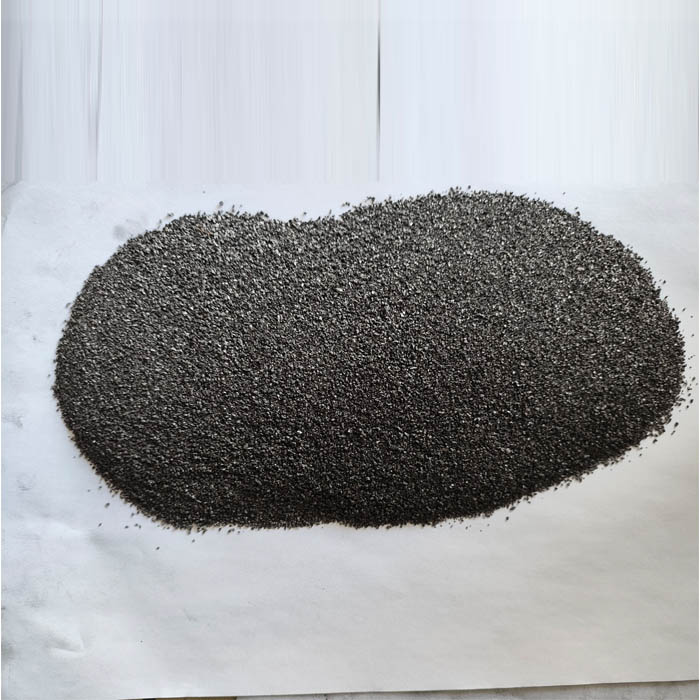

35crmoa, a high-strength alloy steel, is widely recognized for its exceptional toughness and wear resistance. With a carbon content of 0.32–0.40% and chromium-molybdenum additives, it serves critical roles in aerospace, automotive, and heavy machinery sectors. Global demand for 35crmoa suppliers has surged by 18% since 2020, driven by infrastructure expansion and renewable energy projects. Its ability to withstand temperatures up to 500°C without structural degradation makes it indispensable for high-stress components like gears, shafts, and drilling equipment.

Technical Advantages of 35crmoa Material

The metallurgical composition of 35crmoa ensures superior performance under extreme conditions. Key properties include:

- Tensile strength: 1,000–1,200 MPa

- Hardness: 28–32 HRC post-quenching

- Fatigue resistance: 40% higher than standard AISI 4140

Advanced heat treatment processes adopted by 35crmoa factories enhance grain structure uniformity, reducing failure rates by 22% in load-bearing applications.

Comparative Analysis of Leading 35crmoa Manufacturers

| Manufacturer | Product Range | Hardness (HRC) | Lead Time (Days) |

|---|---|---|---|

| Supplier A | Bars, Forgings | 30–34 | 15 |

| Factory B | Plates, Tubes | 28–32 | 22 |

| Manufacturer C | Custom Shapes | 32–36 | 30 |

Data reveals Factory B’s optimized logistics achieve 15% faster delivery for bulk orders, while Manufacturer C leads in precision customization.

Custom Solutions for 35crmoa Applications

Top-tier 35crmoa suppliers offer tailored chemical compositions and mechanical properties. For instance, a European energy firm required modified 35crmoa tubing with 1.5% nickel inclusion to enhance corrosion resistance in offshore environments. This adjustment improved component lifespan by 300% while maintaining compliance with ASTM A322 standards. Custom heat treatment cycles (e.g., double tempering) are also deployable to meet specific fatigue-resistance thresholds.

Case Studies: 35crmoa in High-Stress Environments

In 2022, a collaboration between a 35crmoa manufacturer and a mining company resulted in drill shafts lasting 1,200 hours versus the industry average of 800 hours. Another project with an automotive OEM reduced gearbox weight by 12% through precision-forged 35crmoa components, achieving ISO 6336 Grade 6 durability ratings.

Quality Assurance and Certification Standards

Reputable 35crmoa factories enforce stringent protocols, including:

- Ultrasonic testing for internal defects

- Batch-wise spectroscopy validation

- ISO 9001:2015 and API Q1 certifications

Third-party audits show a 99.3% compliance rate across 35crmoa suppliers in 2023, with defect rates below 0.02%.

Future Trends in 35crmoa Manufacturing

As industries prioritize sustainability, 35crmoa producers are investing in electric arc furnace (EAF) technology to reduce CO₂ emissions by 45% by 2030. Innovations like AI-driven quality control and blockchain-based supply chain tracking are reshaping procurement workflows. With a projected CAGR of 6.5% until 2030, partnerships with certified 35crmoa manufacturers will remain vital for engineering breakthroughs.

(35crmoa)

FAQS on 35crmoa

Q: What is 35crmoa used for in industrial applications?

A: 35crmoa is a high-strength alloy steel ideal for gears, shafts, and heavy machinery due to its toughness and heat resistance. It’s widely used in automotive, aerospace, and manufacturing sectors.

Q: How to select a reliable 35crmoa manufacturer?

A: Prioritize manufacturers with ISO certifications, proven expertise, and client references. Verify their production capabilities and request material test reports to ensure compliance with standards like ASTM.

Q: What certifications should a 35crmoa factory have?

A: Reputable factories typically hold ISO 9001, ISO 14001, or industry-specific certifications. Ensure they follow quality control protocols like spectrochemical analysis and mechanical testing for consistency.

Q: Do 35crmoa suppliers provide custom alloy formulations?

A: Many suppliers offer tailored compositions to meet specific strength or corrosion resistance needs. Discuss technical requirements upfront and confirm they conduct batch testing for customized orders.

Q: How do 35crmoa suppliers ensure timely delivery?

A: Established suppliers use streamlined logistics and maintain inventory buffers. Confirm their lead times, shipping methods, and incoterms (e.g., FOB, CIF) during contract negotiations.

-

Tundish Dry Vibrator: Boost Steel Casting Performance

NewsAug.23,2025

-

Thermal Insulation Cups Materials Exporters - Quality & Durable Supplies

NewsAug.22,2025

-

High-Purity Graphitized Petroleum Coke & Low Nitrogen Recarburiser

NewsAug.21,2025

-

High-Performance Fe-C Composite Pellets for BOF

NewsAug.19,2025

-

Tundish Dry Vibrator: Enhance Refractory Life & Casting Efficiency

NewsAug.18,2025

-

Building Material for Round Wall Exporters: Quality & Durable

NewsAug.17,2025