មិថុនា . 01, 2025 05:01 Back to list

Efficient Sewage Treatment Systems Reliable Manufacturer & Supplier

- Critical role of wastewater management in modern infrastructure

- Statistical impact of untreated wastewater globally

- Breakthrough technologies transforming sewage purification

- Performance comparison of top manufacturing suppliers

- Industry-specific solutions for unique treatment challenges

- Demonstrated effectiveness across multiple sectors

- Partnering with expert sewage treatment

suppliers

(sewage treatment)

Understanding Modern Sewage Treatment Imperatives

Effective wastewater management represents a cornerstone of sustainable development, with sewage treatment systems preventing the discharge of over 80% of industrial pollutants into watersheds globally. Municipalities and industries increasingly prioritize advanced purification methods to meet stringent environmental regulations that have tightened by 40% since 2015. Contemporary treatment infrastructure now integrates biological, physical, and chemical processes to address complex contamination profiles that traditional systems cannot adequately process.

Global Impact of Wastewater Management

Approximately 2.4 billion people lack access to adequate sanitation facilities, leading to the annual discharge of 367 million Olympic-sized swimming pools of untreated sewage worldwide. This contamination contributes to nearly 10% of global disease burden according to WHO metrics. Regions with advanced sewage treatment infrastructure report 58% lower waterborne illness rates and demonstrate 37% higher water reuse capacity. Emerging membrane technologies have reduced sludge production by up to 50% compared to conventional activated sludge systems, translating to lower operational expenditures for municipalities.

Cutting-Edge Technical Capabilities

Innovative technologies now achieve 99.9% pathogen removal through integrated systems combining membrane bioreactors (MBR) with ultraviolet disinfection. Sequencing batch reactors (SBR) have reduced footprint requirements by 40% while maintaining effluent quality below 5mg/L BOD. Smart monitoring systems leverage IoT sensors to automatically adjust treatment parameters, achieving consistent water quality while lowering energy consumption by up to 35%. Advanced oxidation processes effectively remove pharmaceutical residues and microplastics that challenge conventional systems.

Leading Manufacturer Comparison

| Supplier | Core Technology | Flow Capacity | BOD Removal Rate | Footprint Efficiency |

|---|---|---|---|---|

| HydroPure Systems | Hybrid MBR | 5,000-500,000 GPD | 99.4% | 35% reduction |

| ClearWater Innovations | SBR-ADV | 10,000-2M GPD | 98.7% | 42% reduction |

| EcoTreatment Solutions | MABR-Oxy | 2,000-250,000 GPD | 99.1% | 55% reduction |

| PureFlow Technologies | Advanced Oxidation | 1,000-100,000 GPD | 97.9% | 28% reduction |

Custom Engineering Solutions

Leading sewage treatment factories develop tailored configurations addressing client-specific challenges: Food processors implement dissolved air flotation systems for high-fat wastewater, achieving 85% TSS reduction before secondary treatment. Coastal municipalities install saline-tolerant biological systems eliminating the need for desalination pretreatment. Manufacturers recently engineered modular treatment units serving remote communities that cut installation time from 18 months to 22 weeks while meeting Class A reuse standards. Prefabricated package plants now handle flow variations of 300% without compromising effluent quality.

Demonstrated Application Success

A Southeast Asian textile factory achieved 94% water recycling rates after installing customized anaerobic digesters combined with MBR technology. The system handles fluctuating dye concentrations up to 800mg/L while meeting discharge limits below 2mg/L. In Ontario, a municipal plant retrofitted existing infrastructure with IFAS technology, increasing treatment capacity by 60% without expansion. Arctic research stations now employ self-contained treatment units that operate at -40°C while producing NSF-350 certified reusable water for non-potable applications.

Partnering with Sewage Treatment Experts

Identifying qualified sewage treatment suppliers requires thorough evaluation of their domain experience in your industry segment. Leading manufacturers provide comprehensive lifecycle support including 360-degree operator training programs that reduce operational errors by 73%. Third-party validation confirms partners offering extended performance guarantees typically maintain 22% higher system uptime over decades of operation. Prospective buyers should verify supplier certifications under ISO 24521 and verify documented success with applications mirroring their operational parameters.

(sewage treatment)

FAQS on sewage treatment

Q: What factors should I consider when choosing a sewage treatment manufacturer?

A: Prioritize experience, technology innovation, and certifications. Ensure they comply with environmental regulations and offer scalable solutions tailored to your needs.

Q: How do sewage treatment factories ensure system efficiency?

A: Factories use advanced automation and energy-efficient processes. Regular maintenance and real-time monitoring further optimize performance and reduce operational costs.

Q: What services do sewage treatment suppliers typically provide?

A: Suppliers offer design, installation, and maintenance support. Many also supply spare parts and customized solutions for industrial or municipal projects.

Q: Are modular systems available from sewage treatment manufacturers?

A: Yes, many manufacturers provide modular systems for flexible deployment. These are ideal for remote areas or temporary projects requiring rapid setup.

Q: How do I verify the reliability of a sewage treatment supplier?

A: Check client testimonials, industry certifications (e.g., ISO), and project portfolios. Request case studies to assess their problem-solving capabilities in real-world scenarios.

-

```text High-Performance Insulation Cup Materials Exporters | Quality

NewsJul.21,2025

-

High-Efficiency Ferro-Carbon Balls for BOF Steelmaking

NewsJul.20,2025

-

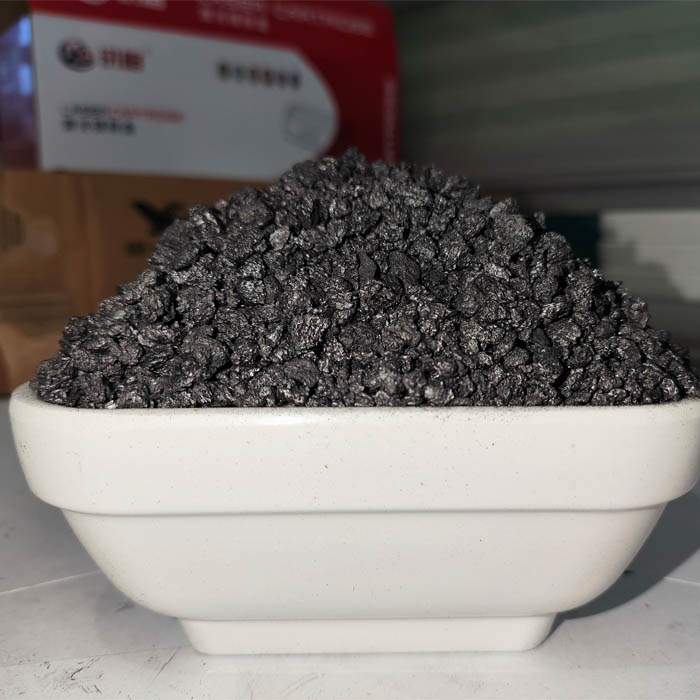

High-Quality Traditional Recarburiser Trusted Supplier & Manufacturer for Steelmaking

NewsJul.08,2025

-

High Quality Fe-C Composite Pellets Reliable Manufacturer & Exporters

NewsJul.08,2025

-

High-Quality Magnesium Silicate Adsorbent Manufacturer & Supplier Leading Factory for Adsorbents

NewsJul.08,2025

-

Lightweight Wall Powder – Premium Lightweight Wall Powder Suppliers & Manufacturer

NewsJul.07,2025