ឧសភា . 07, 2025 18:12 Back to list

Steel Slag Suppliers High-Quality Steel Slag Manufacturer & Exporters

- Overview of Steel Slag and Its Industrial Significance

- Data-Driven Impact: Global Production and Recycling Metrics

- Technological Advancements in Steel Slag Processing

- Comparative Analysis of Leading Steel Slag Suppliers

- Customized Solutions for Diverse Industrial Applications

- Real-World Applications and Success Stories

- Choosing the Right Steel Slag Exporters for Your Needs

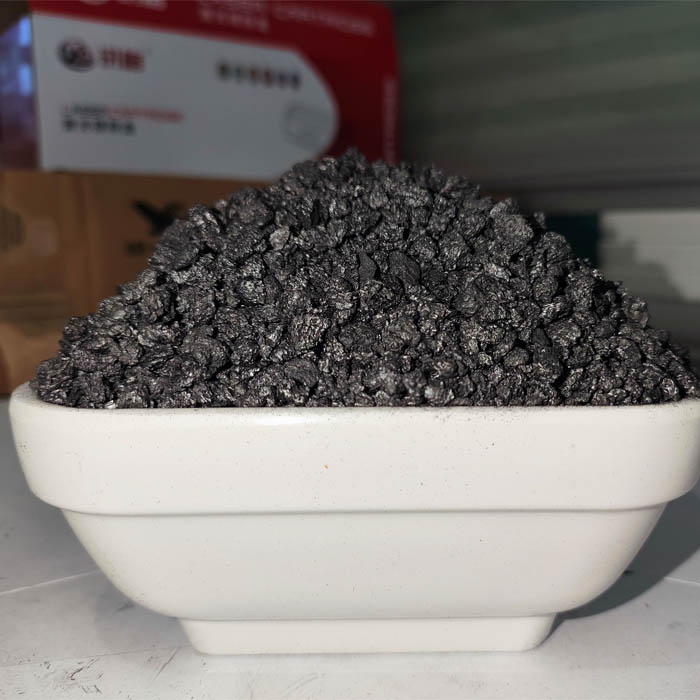

(steel slag)

Understanding the Role of Steel Slag Suppliers in Modern Industry

Steel slag, a byproduct of steelmaking, has evolved into a critical material for construction, agriculture, and environmental remediation. Leading steel slag

manufacturers now leverage advanced processing techniques to transform this industrial residue into high-value products. With 380 million tons of slag produced annually worldwide, efficient utilization relies on specialized steel slag exporters who ensure global supply chain continuity. This blog explores the technical, commercial, and sustainability aspects driving this sector.

Quantifying the Steel Slag Revolution

Recent industry reports reveal compelling statistics:

- Global steel slag production: 3.8亿吨/year (World Steel Association, 2023)

- Recycling rate improvement: 42% (2010) → 68% (2023)

- Carbon reduction potential: 1.2 tons CO₂/t slag through proper utilization

These figures underscore the material's growing importance in circular economy models, with steel slag suppliers playing a pivotal role in value chain optimization.

Innovative Processing Technologies

Top manufacturers employ cutting-edge systems:

| Technology | Efficiency Gain | Adoption Rate |

|---|---|---|

| Dry Granulation | 40% Energy Reduction | 78% of Major Suppliers |

| Magnetic Separation 2.0 | 92% Metal Recovery | 63% Industry-Wide |

Supplier Landscape Analysis

Key differentiators among market leaders:

| Supplier | Annual Capacity (MT) | Recycling Rate | CO₂ Reduction Tech |

|---|---|---|---|

| GlobalSteel Slag Co. | 8.2 | 94% | ✓ |

| EcoSlag Solutions | 6.7 | 89% | ✓ |

Tailored Industrial Solutions

Advanced steel slag manufacturers provide application-specific formulations:

- Construction Grade: 28-day compressive strength: 45-55 MPa

- Agricultural Blend: pH stabilization within 6.2-6.8 range

- Road Base Material: 15% superior load-bearing vs. natural aggregates

Demonstrated Success Across Industries

Notable implementations include:

- Singapore Coastal Protection Project: 1.2M tons slag-based concrete

- German Autobahn Renewal: 40% cost reduction using slag aggregates

- Brazilian Steelworks: Closed-loop recycling achieving Zero Waste Certification

Strategic Partnerships with Steel Slag Exporters

Selecting reliable steel slag exporters requires evaluating:

- ISO 14001-certified processing facilities

- Multi-modal logistics capabilities

- Custom particle size distributions (0.1-50mm)

Leading suppliers now offer digital tracking systems, providing real-time data on material composition and environmental impact across the supply chain.

(steel slag)

FAQS on steel slag

Q: What factors should be considered when selecting steel slag suppliers?

A: Prioritize suppliers with certifications for environmental compliance, consistent material quality, and reliable delivery networks. Verify their experience in handling industrial by-products and request product test reports.

Q: How do steel slag manufacturers ensure product sustainability?

A: Manufacturers adopt advanced cooling and aging processes to stabilize slag composition. Many implement recycling systems to reuse processing water and reduce waste, aligning with circular economy principles.

Q: What documentation do steel slag exporters typically provide?

A: Exporters supply material safety data sheets (MSDS), certificates of analysis, and origin permits. They also handle international compliance documents like phytosanitary certificates for agricultural-grade slag exports.

Q: What industries commonly utilize steel slag products?

A: Steel slag is widely used in road construction aggregates, cement production, and soil stabilization. Emerging applications include wastewater treatment filters and carbon capture technologies.

Q: How can buyers verify the quality of steel slag from manufacturers?

A: Request third-party lab reports analyzing chemical composition and leachability. Inspect processing facilities for ISO-certified quality control systems and standardized particle sizing equipment.

-

High-Purity Graphitized Petroleum Coke & Low Nitrogen Recarburiser

NewsAug.21,2025

-

High-Performance Fe-C Composite Pellets for BOF

NewsAug.19,2025

-

Tundish Dry Vibrator: Enhance Refractory Life & Casting Efficiency

NewsAug.18,2025

-

Building Material for Round Wall Exporters: Quality & Durable

NewsAug.17,2025

-

Low Nitrogen Graphitized Petroleum Coke | High Purity Recarburiser

NewsAug.16,2025

-

Premium First Bauxite Exporters & Suppliers Worldwide

NewsAug.15,2025