Aug . 08, 2025 02:00 Back to list

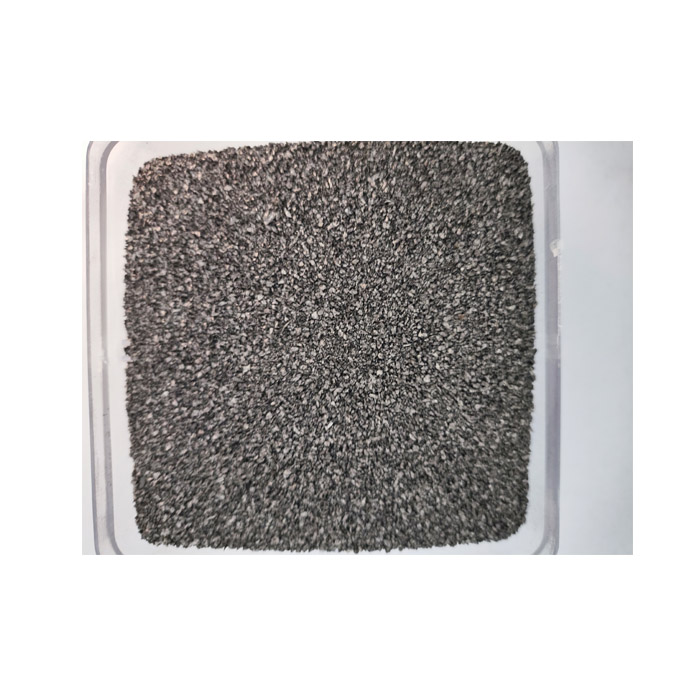

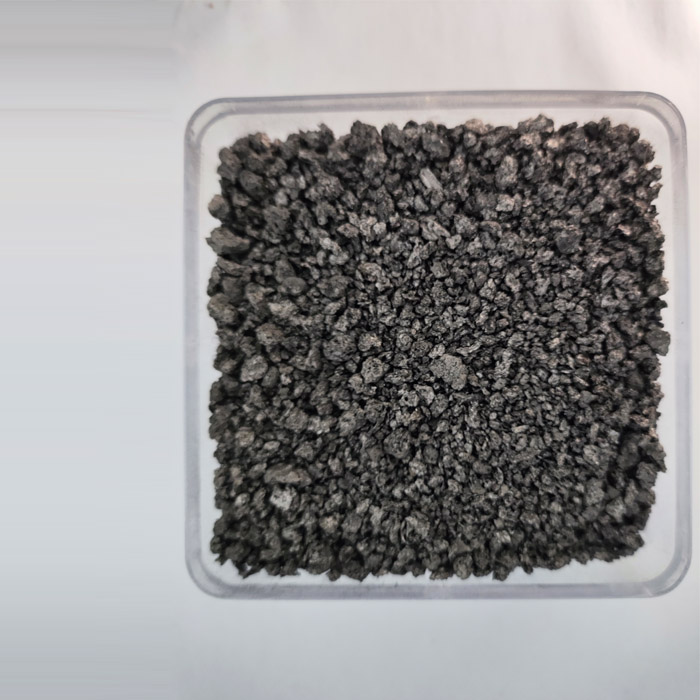

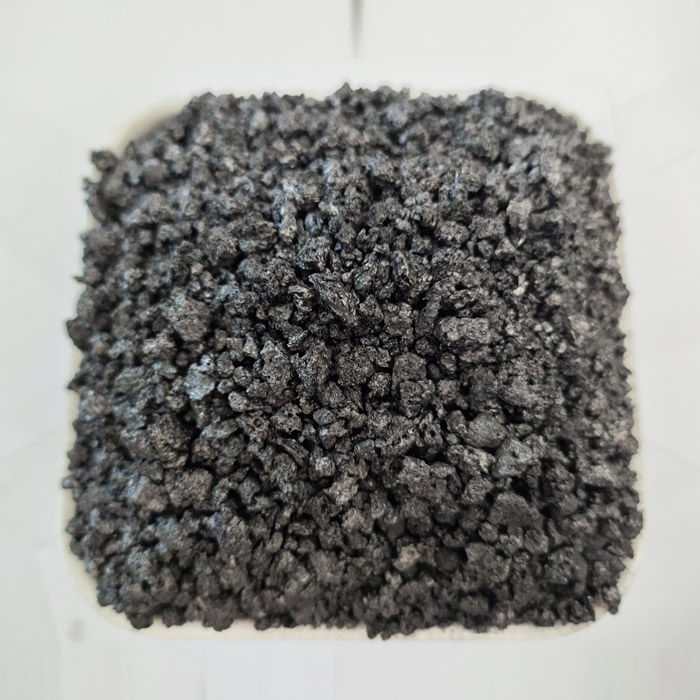

High Purity Graphitized Petroleum Coke | Low N Recarburiser

In the relentless pursuit of high-quality metal production, the role of advanced carbon additives cannot be overstated. Among these, Graphitized Petroleum Coke/Low Nitrogen Recarburiser stands out as a superior solution, offering unparalleled purity and performance. This comprehensive guide delves into its critical role, manufacturing intricacies, diverse applications, and the competitive advantages it brings to modern metallurgy.

Industry Trends and the Demand for Purity

The global steel and foundry industries are undergoing significant transformations, driven by escalating demands for higher quality, reduced environmental impact, and greater cost efficiency. Traditional recarburizers often fall short in meeting these stringent requirements, particularly concerning sulfur, nitrogen, and ash content. This is where Graphitized Petroleum Coke/Low Nitrogen Recarburiser emerges as a vital component.

Current trends indicate a clear shift towards advanced carbon solutions. According to a report by Grand View Research, the global graphite market size, which includes graphitized petroleum coke, was valued at USD 17.5 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 6.2% from 2023 to 2030. This growth is primarily fueled by increasing demand from metallurgy, electric vehicles, and energy storage sectors, highlighting the strategic importance of high-purity carbon materials. Specifically, in iron and steel production, the need for low-nitrogen and low-sulfur additives is paramount to prevent defects and ensure mechanical integrity of the final products.

Understanding Graphitized Petroleum Coke/Low Nitrogen Recarburiser: Technical Parameters

Graphitized Petroleum Coke/Low Nitrogen Recarburiser is a highly refined carbon additive produced from high-quality petroleum coke through an intense graphitization process. This process transforms amorphous carbon into a crystalline graphite structure, significantly enhancing its carbon content and reducing impurities to trace levels. The "low nitrogen" aspect is particularly crucial, as excessive nitrogen can lead to porosity, brittle fracture, and reduced mechanical properties in cast iron and steel.

Typical Product Specifications:

The efficacy of Graphitized Petroleum Coke/Low Nitrogen Recarburiser is defined by its precise technical parameters. These parameters are critical for ensuring optimal performance in metallurgical applications, influencing everything from carbon recovery rates to the final mechanical properties of the metal.

| Parameter | Typical Value Range | Significance in Metallurgy |

|---|---|---|

| Fixed Carbon (FC) | 98.5% - 99.5% min | High carbon content ensures efficient carbonization, minimizing additive consumption and maximizing carbon recovery. This directly contributes to cost savings and consistency in metal composition. |

| Sulfur (S) | 0.03% - 0.05% max | Ultra-low sulfur content is vital to prevent embrittlement and hot cracking in steel and cast iron, especially in applications requiring high ductility and strength. Reduces the need for desulfurization. |

| Nitrogen (N) | 80 ppm - 300 ppm max | Extremely low nitrogen content prevents gas porosity, blowholes, and reduces the risk of 'pinholes' in castings, ensuring dense and defect-free metal structures. Critical for high-performance alloys. |

| Ash Content | 0.3% - 0.5% max | Low ash content reduces slag formation, leading to cleaner metal, less refractory wear, and lower cleaning costs. It also means less non-metallic inclusions in the final product. |

| Volatile Matter (VM) | 0.3% - 0.8% max | Low volatile matter ensures stability during melting, minimizing smoke, flame, and gas evolution, leading to a safer and more efficient working environment. Contributes to consistent carbon absorption. |

| Moisture | 0.5% max | Low moisture content prevents steam generation during melting, which can cause splashes and introduce hydrogen defects into the metal. Ensures accurate weighing and consistent material delivery. |

| Particle Size | 0.5-5mm, 1-3mm, 3-8mm (customizable) | Optimized particle size ensures rapid dissolution and high carbon recovery rate, suitable for various furnace types (induction, arc) and applications. Prevents floating or segregation. |

The Meticulous Process: Manufacturing Graphitized Petroleum Coke/Low Nitrogen Recarburiser

The production of high-quality Graphitized Petroleum Coke/Low Nitrogen Recarburiser is a complex, energy-intensive process requiring precise control over extreme temperatures and material handling. It is not merely about heating petroleum coke; it involves a series of sophisticated steps to achieve the desired purity and crystalline structure.

Manufacturing Process Flow:

While a dynamic video or interactive diagram would best illustrate this, here is a detailed textual representation of the core stages. Imagine arrows connecting these steps, indicating the progression of the material.

-

➤

Raw Material Selection & Preparation

Material: High-quality calcined petroleum coke (CPC) is the primary raw material. Its selection is crucial; only CPC with low sulfur, low ash, and good graphitizability is chosen. This pre-screening ensures the final product's purity. The CPC is typically crushed and screened to a consistent particle size suitable for subsequent processing.

-

➤

Graphitization Furnace Loading

The prepared CPC is carefully loaded into specialized Acheson furnaces or internal series graphitization furnaces. These furnaces are designed to withstand extremely high temperatures (up to 3000°C) and provide a controlled environment for the graphitization reaction. Precise loading ensures uniform heating.

-

➤

High-Temperature Graphitization

This is the core of the process. The loaded furnace is heated gradually over several days to temperatures between 2500°C and 3000°C. At these extreme temperatures, the amorphous carbon atoms in the petroleum coke rearrange into the highly ordered hexagonal crystalline structure of graphite. This process significantly reduces impurities (sulfur, nitrogen, volatile matter) through volatilization and sublimation, transforming them into gases that are safely vented or captured. The high temperature also reduces resistivity and increases thermal conductivity. This is a form of thermal processing, analogous to advanced heat treatment.

-

➤

Cooling & Unloading

After the graphitization phase, the furnace is slowly cooled down over several days to room temperature. This controlled cooling prevents thermal shock and ensures the structural integrity of the newly formed graphitized coke. Once cooled, the material is carefully unloaded from the furnace.

-

➤

Crushing, Screening & Sizing

The large blocks of graphitized petroleum coke are then crushed to the desired particle sizes. Multiple stages of crushing and screening (e.g., using vibrating screens) ensure a precise particle size distribution (e.g., 0.5-5mm, 1-3mm, 3-8mm) tailored for various applications. This step ensures optimal dissolution rates in different furnace types.

-

➤

Quality Control & Inspection

Every batch undergoes rigorous quality control. Samples are taken and analyzed for Fixed Carbon, Sulfur, Nitrogen, Ash, Volatile Matter, and moisture content using advanced laboratory equipment. Inspection Standards: We adhere strictly to international standards such as ISO 9001 for quality management and conduct tests in accordance with ASTM (e.g., ASTM D3461 for graphitized petroleum coke properties) and Chinese national standards (e.g., GB/T 19001). This ensures that every product meets specified technical parameters and delivers consistent performance.

-

➤

Packaging & Storage

The final product is packaged in durable bags (e.g., 25kg bags, 1-ton jumbo bags) to protect against moisture and contamination during transit and storage. Proper labeling ensures traceability. This careful packaging preserves the product's integrity until it reaches the end-user.

This entire process, particularly the high-temperature graphitization, is critical for achieving the ultra-low nitrogen content and high carbon purity that define Graphitized Petroleum Coke/Low Nitrogen Recarburiser.

Application Scenarios and Industry Advantages

Graphitized Petroleum Coke/Low Nitrogen Recarburiser is a versatile and indispensable additive across several heavy industries, where precise carbon control and impurity reduction are paramount. Its superior properties translate directly into enhanced product quality, increased operational efficiency, and significant cost savings. The typical service life of our recarburizer is tied to its consumption rate in a given metallurgical process; however, its inherent stability and low impurity profile ensure it performs consistently until fully consumed, contributing to the longevity and quality of the final metal product.

Applicable Industries:

- Metallurgy Industry: This is the primary sector.

- Steelmaking: Used in electric arc furnaces (EAF) and induction furnaces as a recarburizer, especially for high-grade steels (e.g., bearing steel, spring steel, tool steel) where low nitrogen and sulfur are critical to prevent defects like pinholes and cold shortness.

- Foundry (Cast Iron Production): Essential for producing high-quality ductile iron, grey iron, and malleable iron. It helps control carbon content, promotes graphite formation, and reduces chilling tendency. Its low nitrogen content is crucial for preventing porosity and ensuring good machinability.

- Special Alloys: Used in the production of ferroalloys and other specialized alloys where precise carbon addition without introducing harmful impurities is required.

- Aluminum Industry: While less common as a recarburizer, graphitized petroleum coke is used in anode production for aluminum smelting due to its high purity and electrical conductivity.

- Chemical Industry: Used as a raw material for producing graphite electrodes, carbon blocks, and other graphite products due to its high carbon content and graphitic structure.

- Recarburizer for Industrial Furnaces: Beyond specific metal production, it serves as a general carbon source to adjust carbon levels in various industrial melting processes.

Product Advantages in Typical Application Scenarios:

- Enhanced Carbon Recovery: With fixed carbon levels consistently above 98.5%, our Graphitized Petroleum Coke/Low Nitrogen Recarburiser offers superior carbon absorption rates (typically 90-95% in induction furnaces), leading to less material consumption and reduced costs compared to lower-grade alternatives. This efficiency is critical for maintaining tight carbon specifications.

- Superior Metal Quality: The ultra-low sulfur (max 0.05%) and nitrogen (max 300 ppm) content prevents defects such as porosity, pinholes, and brittleness in the final metal product. This translates to stronger, more ductile, and aesthetically superior castings and steel. For instance, in ductile iron production, a lower nitrogen content from the recarburizer significantly reduces the risk of 'exploded' graphite nodules, ensuring proper spheroidization.

- Energy Saving: Due to its high purity and excellent thermal conductivity, Graphitized Petroleum Coke/Low Nitrogen Recarburiser dissolves rapidly and efficiently in the molten metal. This rapid dissolution reduces the required holding time in the furnace, thereby leading to substantial energy savings and increased furnace throughput. Less energy input per ton of metal produced directly lowers operational costs.

- Environmental Benefits: The low volatile matter content (max 0.8%) means less smoke and fewer harmful emissions during melting, contributing to a cleaner and safer working environment. This aligns with increasingly stringent environmental regulations faced by metallurgical plants globally.

- Corrosion Resistance (Indirect): While the recarburizer itself isn't applied for corrosion resistance, its contribution to producing high-quality, defect-free metal products enhances the intrinsic corrosion resistance of the final castings or steel. For example, reducing pinholes and porosity through low nitrogen content means fewer potential sites for corrosive attack, increasing the overall lifespan of the fabricated components in challenging environments like industrial plumbing, chemical processing, or marine applications.

Choosing Your Partner: Manufacturer Comparison

Selecting the right supplier for Graphitized Petroleum Coke/Low Nitrogen Recarburiser is as crucial as the product itself. The market is populated by numerous manufacturers, but not all offer the same level of quality consistency, technical support, and reliability. Here's a comparative overview highlighting why Xingtai Luxi Carbon Co., Ltd. stands out.

| Feature | Xingtai Luxi Carbon Co., Ltd. (Us) | Typical Competitor A (General Supplier) | Typical Competitor B (Low-Cost Producer) |

|---|---|---|---|

| Product Purity (Fixed Carbon) | 98.5% - 99.5% min | 97.0% - 98.5% min | 96.0% - 97.5% min |

| Nitrogen Content (ppm) | < 300 ppm (Often < 150 ppm) | 300 - 800 ppm | > 800 ppm |

| Sulfur Content (%) | < 0.05% | 0.05% - 0.10% | > 0.10% |

| Quality Control & Standards | ISO 9001 certified, ASTM, strict in-house lab testing, third-party verification available. Each batch traceable. | Basic QC, may lack specific certifications or external audits. Variable batch consistency. | Minimal QC, focus on volume. High batch variability. |

| Customization Options | Extensive particle size range, specific chemical profiles, tailored packaging. Full technical consultation. | Limited standard sizes, less flexibility for specific needs. | Typically only standard, high-volume sizes. No customization. |

| Technical Support & Expertise | Dedicated technical team, R&D support, application-specific advice, problem-solving. Over 20 years of experience. | Basic sales support, limited technical insights. | Primarily transactional, no technical support. |

| Delivery & Logistics | Reliable global logistics, timely delivery, flexible order quantities. Strong supply chain. | Standard shipping, potential delays, less flexible on urgent orders. | Longer lead times, less reliable shipping. |

| Pricing Strategy | Competitive for premium quality; value-driven, focusing on long-term benefits and reduced operational costs. | Mid-range, balance of cost and quality. | Lowest price point, often sacrificing quality and consistency. |

| Market Reputation | Known for high purity, consistency, and excellent customer service. Trusted by major metallurgical players. | Average market reputation, often seen as an alternative. | Known for low prices, but inconsistent quality. |

Our commitment to rigorous quality control, deep industry expertise, and client-centric solutions sets us apart. We understand that in metallurgical processes, consistency and reliability are not just features; they are necessities.

Tailored Solutions: Customization for Your Needs

Every metallurgical operation has unique requirements, influenced by furnace type, metal composition, desired final properties, and budget constraints. Recognizing this, we offer highly customizable solutions for our Graphitized Petroleum Coke/Low Nitrogen Recarburiser. Our technical team works closely with clients to understand their specific challenges and objectives.

Customization options include:

- Particle Size Distribution: We can produce specific sieve fractions (e.g., finer grades for ladle additions, coarser grades for furnace additions) to optimize dissolution rates and carbon recovery in various melting processes.

- Chemical Profile Adjustment: While our standard product is already of high purity, for extremely sensitive applications, we can further refine impurity levels (e.g., ultra-low sulfur for certain stainless steels).

- Packaging Solutions: From small 25kg bags for manual handling to large 1-ton bulk bags for automated feeding systems, we can tailor packaging to suit operational logistics and storage capabilities.

- Blended Products: In some cases, a blend of different carbon materials might be optimal. We can advise and supply custom blends to meet specific metallurgical goals.

Proven Success: Application Case Studies

Our Graphitized Petroleum Coke/Low Nitrogen Recarburiser has consistently delivered exceptional results for our clients worldwide. Here are a few examples demonstrating its real-world impact:

Case Study 1: High-Performance Ductile Iron Foundry

Client: A leading ductile iron foundry in North America, struggling with inconsistent mechanical properties and pinhole defects in their high-strength castings due to fluctuating nitrogen levels from their existing recarburizer.

Solution: We recommended and supplied our Graphitized Petroleum Coke/Low Nitrogen Recarburiser with guaranteed nitrogen content below 150 ppm and fixed carbon above 99%. Our technical team provided on-site consultation for optimal addition methods.

Results: Within three months, the foundry reported a 70% reduction in pinhole defects and a significant improvement in the consistency of tensile strength and elongation. Their overall scrap rate for critical components decreased by 12%, leading to substantial cost savings and improved customer satisfaction. The rapid dissolution rate also cut their melting time by an average of 5 minutes per heat, leading to energy savings.

Case Study 2: Precision Steel Manufacturer (EAF)

Client: A European manufacturer of specialized alloy steels, facing challenges with excessive sulfur pick-up and poor carbon recovery in their Electric Arc Furnace (EAF) operations, impacting their strict purity requirements for automotive components.

Solution: We provided our Graphitized Petroleum Coke/Low Nitrogen Recarburiser with ultra-low sulfur content (0.03% max) and a tailored particle size for EAF injection.

Results: The client achieved an impressive 95% carbon recovery rate, a 15% improvement from their previous supplier. More critically, the sulfur content in their final steel product consistently met their stringent specifications without requiring additional desulfurization steps, saving both time and costly desulfurization agents. This led to a net cost reduction of 8% per ton of steel produced.

Our Commitment to EEAT and Trustworthiness

At Xingtai Luxi Carbon Co., Ltd., we don't just supply products; we build partnerships based on Expertise, Experience, Authoritativeness, and Trustworthiness (EEAT).

Expertise & Experience:

- Deep Industry Knowledge: With over two decades of experience in carbon materials, our team possesses an unparalleled understanding of metallurgical processes and the nuanced impact of carbon additives. We speak your language – be it carbon equivalent, chilling tendency, or nodularity.

- Practical Application Experience: Our technical support goes beyond theoretical knowledge. We have worked with hundreds of foundries and steel mills globally, gaining invaluable practical experience in optimizing recarburizer usage for diverse furnace types (induction, arc, cupola) and metal compositions.

- Continuous R&D: We invest significantly in research and development to refine our manufacturing processes and product formulations, staying at the forefront of carbon material innovation.

Authoritativeness & Trustworthiness:

- Industry Certifications: Our manufacturing facility is ISO 9001:2015 certified, guaranteeing a robust Quality Management System. Our products conform to relevant ASTM standards, ensuring consistent quality and performance.

- Long-Standing Reputation: Established over 20 years ago, Xingtai Luxi Carbon Co., Ltd. has built a reputation for reliability and integrity in the carbon industry, serving clients across Asia, Europe, North America, and beyond.

- Transparent Operations: We welcome client audits and provide comprehensive Certificates of Analysis (CoA) for every shipment, ensuring complete transparency regarding product specifications.

- Partnerships: We have long-term strategic partnerships with leading metallurgical research institutes and major industrial groups, facilitating continuous improvement and market responsiveness.

Delivery & Warranty:

Delivery Cycle: Our standard delivery time ranges from 7 to 20 working days, depending on order volume and destination. Expedited shipping options are available upon request. We maintain healthy stock levels for popular specifications to minimize lead times.

Quality Assurance & Warranty: We guarantee that our Graphitized Petroleum Coke/Low Nitrogen Recarburiser meets the specified technical parameters as per our Certificate of Analysis. In the unlikely event of any deviation from agreed specifications, we offer a comprehensive return or replacement policy. Our commitment extends beyond delivery; we stand by the quality of our product and its performance in your application.

Customer Support:

Our dedicated customer support team is available 24/7 to assist with inquiries, technical issues, and order tracking. We offer multilingual support to cater to our global clientele. From initial consultation to post-delivery follow-up, your satisfaction is our priority. Contact us via phone, email, or our website's live chat for prompt assistance.

Frequently Asked Questions (FAQ)

Q1: What is the primary difference between Graphitized Petroleum Coke and Calcined Petroleum Coke (CPC)?

A1: The key difference lies in the manufacturing process and resulting properties. CPC is produced at around 1200-1350°C, removing moisture and volatile matter. Graphitized Petroleum Coke/Low Nitrogen Recarburiser undergoes an additional, much higher temperature treatment (2500-3000°C) which transforms its amorphous carbon structure into a crystalline graphitic structure. This graphitization significantly reduces impurities like sulfur and nitrogen to trace levels, increases fixed carbon content, and improves electrical and thermal conductivity, making it a superior recarburizer.

Q2: Why is low nitrogen content crucial for recarburizers in foundry applications?

A2: Nitrogen is a powerful carbide stabilizer in cast iron, hindering the formation of beneficial graphite and promoting the formation of 'pinholes' (small gas pores) and porosity in castings. High nitrogen content can lead to reduced mechanical properties, poor machinability, and increased scrap rates. Therefore, a low nitrogen recarburizer like Graphitized Petroleum Coke/Low Nitrogen Recarburiser is essential for producing high-quality, defect-free cast iron, especially ductile iron.

Q3: How does particle size affect the performance of the recarburizer?

A3: Particle size is critical for optimal dissolution. Finer particles (e.g., 0.5-1mm) dissolve more rapidly, ideal for ladle additions or rapid carbon adjustment. Coarser particles (e.g., 3-8mm) are better for furnace additions, providing slower, more consistent carbon pickup without excessive dusting or floating. Choosing the correct particle size for your specific furnace type and addition method maximizes carbon recovery and minimizes losses.

Q4: Can Graphitized Petroleum Coke/Low Nitrogen Recarburiser be used in Electric Arc Furnaces (EAFs)?

A4: Absolutely. Its high purity, consistent fixed carbon, and very low sulfur and nitrogen content make it an excellent choice for EAFs. It provides rapid and efficient carbon addition, helps to form a foamy slag for arc stability, and contributes to the overall cleanliness of the steel, especially critical for high-grade steel production where impurity control is paramount.

Q5: What are the typical carbon recovery rates with this product?

A5: Carbon recovery rates vary depending on the furnace type, operating practices, and specific grade of recarburizer used. However, with high-quality Graphitized Petroleum Coke/Low Nitrogen Recarburiser, typical recovery rates in induction furnaces range from 90% to 95%, and in EAFs, they can also be very high, often exceeding 85-90%, depending on the injection method and slag conditions. Its high density and rapid dissolution minimize carbon loss.

Q6: What inspection standards do you follow for quality assurance?

A6: We adhere to stringent international and national quality standards. Our manufacturing processes are ISO 9001:2015 certified. Product testing is conducted in accordance with relevant ASTM International standards (e.g., ASTM D3461 for graphitized petroleum coke) and national Chinese standards. Every batch comes with a detailed Certificate of Analysis (CoA) to confirm all specified parameters.

Q7: How does this product contribute to energy savings?

A7: The high purity and rapid dissolution rate of Graphitized Petroleum Coke/Low Nitrogen Recarburiser mean that less material is needed to achieve the desired carbon level, and it dissolves quickly. This reduces the time the metal needs to spend in the furnace for carbon adjustment, directly leading to lower electricity or fuel consumption and increased furnace throughput. Less energy wasted on inefficient dissolution results in significant operational cost reductions.

For more detailed technical specifications or to discuss your specific requirements for Graphitized Petroleum Coke/Low Nitrogen Recarburiser, please do not hesitate to contact our expert team. We are committed to providing you with the highest quality products and unparalleled service.

References & Further Reading:

- Grand View Research. (2023). Graphite Market Size, Share & Trends Analysis Report. https://www.grandviewresearch.com/industry-analysis/graphite-market

- Carbon Journal. (2022). Effects of Nitrogen in Cast Iron: A Review. Available in academic databases (e.g., ScienceDirect, Scopus). Example: https://www.sciencedirect.com/journal/carbon (Note: Specific article link needs to be found via database search for "nitrogen cast iron review")

- ASM International. (2020). ASM Handbook, Volume 15: Casting. (Specific chapters on cast iron metallurgy and carbon control). Example: https://www.asminternational.org/web/handbooks (Specific book/chapter link needs to be identified)

- ASTM International. (Latest Edition). ASTM D3461: Standard Test Method for Ash in Graphitized Petroleum Coke. https://www.astm.org/Standards/D3461

This is the last article

-

High Purity Graphitized Petroleum Coke | Low N Recarburiser

NewsAug.08,2025

-

Fe-C Composite Pellets for BOF: Enhance Steelmaking Efficiency

NewsAug.07,2025

-

Eco-Friendly Granule Covering Agent | Dust & Caking Control

NewsAug.06,2025

-

Fe-C Composite Pellets for BOF: High-Efficiency & Cost-Saving

NewsAug.05,2025

-

Premium Tundish Covering Agents Exporters | High Purity

NewsAug.04,2025

-

Fe-C Composite Pellets for BOF | Efficient & Economical

NewsAug.03,2025