Jan . 26, 2025 02:12 Back to list

Vermiculite

Understanding the nuances of resistance to oxidation is crucial for professionals seeking to select premium materials for a variety of industries, ranging from aerospace to culinary arts. Oxidation, a chemical reaction where materials interact with oxygen, often leads to degradation or material failure, which underlines the significance of using oxidation-resistant substances in critical applications.

The realm of electronics also showcases a critical demand for materials with high oxidation resistance. Copper and aluminum, commonly used in electrical components, are prone to oxidizing, which can impede electrical conductivity. Anodizing aluminum creates an oxide layer that guards against further oxidation, ensuring continued efficiency and longevity of electrical devices. Engineers must thoroughly understand these processes to enhance device performance and reliability. For manufacturers and industrial leaders, trustworthiness in material selection is fundamental. When partnering with suppliers, ensuring that materials meet stringent standards for oxidation resistance is non-negotiable. Certifications from recognized bodies attest to the quality and reliability of these materials, allowing businesses to maintain high standards of production and safety. Companies like Dupont and BASF offer reliable anti-oxidation solutions across several sectors, demonstrating trustworthiness through years of dedicated research and consistent product delivery. In conclusion, mastery of oxidation resistance not only demands an understanding of the scientific principles at play but also necessitates informed decisions based on industry-specific requirements and real-world experiences. The continuous advancement in material science offers exciting prospects for developing even more robust materials that push the boundaries of durability and performance, ensuring safety and efficiency in innumerable applications. Whether you're selecting cookware or engineering aircraft components, the principles of resistance to oxidation remain an essential axis around which quality and excellence revolve.

The realm of electronics also showcases a critical demand for materials with high oxidation resistance. Copper and aluminum, commonly used in electrical components, are prone to oxidizing, which can impede electrical conductivity. Anodizing aluminum creates an oxide layer that guards against further oxidation, ensuring continued efficiency and longevity of electrical devices. Engineers must thoroughly understand these processes to enhance device performance and reliability. For manufacturers and industrial leaders, trustworthiness in material selection is fundamental. When partnering with suppliers, ensuring that materials meet stringent standards for oxidation resistance is non-negotiable. Certifications from recognized bodies attest to the quality and reliability of these materials, allowing businesses to maintain high standards of production and safety. Companies like Dupont and BASF offer reliable anti-oxidation solutions across several sectors, demonstrating trustworthiness through years of dedicated research and consistent product delivery. In conclusion, mastery of oxidation resistance not only demands an understanding of the scientific principles at play but also necessitates informed decisions based on industry-specific requirements and real-world experiences. The continuous advancement in material science offers exciting prospects for developing even more robust materials that push the boundaries of durability and performance, ensuring safety and efficiency in innumerable applications. Whether you're selecting cookware or engineering aircraft components, the principles of resistance to oxidation remain an essential axis around which quality and excellence revolve.

Latest news

-

Thermal Insulation Cups Materials Exporters - Quality & Durable Supplies

NewsAug.22,2025

-

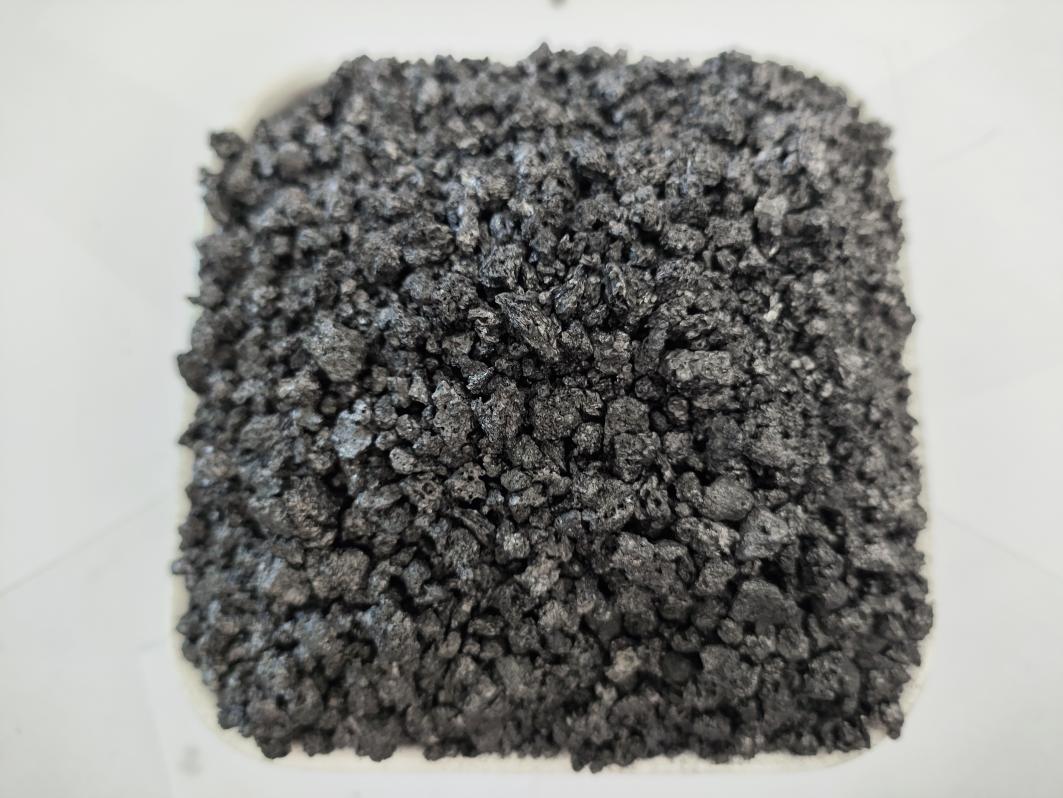

High-Purity Graphitized Petroleum Coke & Low Nitrogen Recarburiser

NewsAug.21,2025

-

High-Performance Fe-C Composite Pellets for BOF

NewsAug.19,2025

-

Tundish Dry Vibrator: Enhance Refractory Life & Casting Efficiency

NewsAug.18,2025

-

Building Material for Round Wall Exporters: Quality & Durable

NewsAug.17,2025

-

Low Nitrogen Graphitized Petroleum Coke | High Purity Recarburiser

NewsAug.16,2025