Jan . 09, 2025 13:51 Back to list

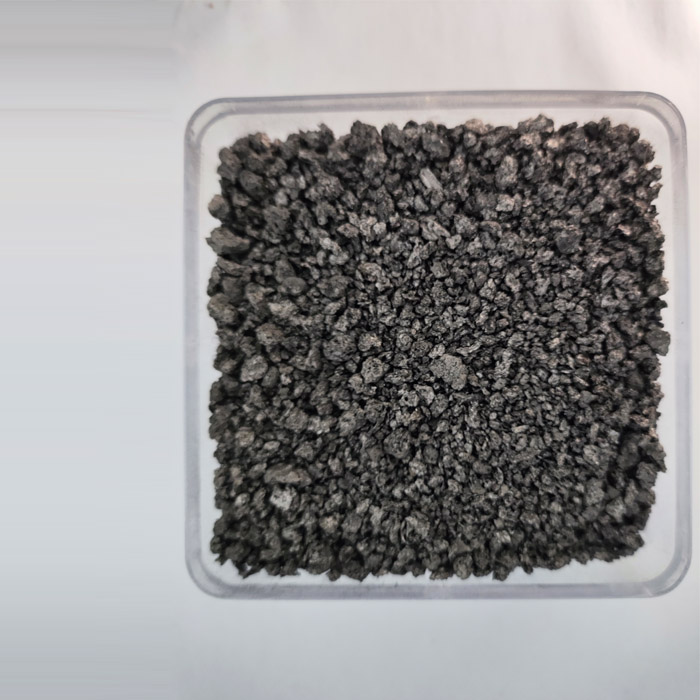

Graphitized Petroleum Coke|Gpc

Carbon raiser, an essential component in metallurgy, has gained notable attention in the industry for its capability to significantly enhance the quality of steel and iron products. This material, predominantly comprised of carbon in high concentration, plays a critical role in the manufacturing processes where its addition is crucial for achieving desired properties in the end product.

Trustworthiness is further reinforced by testimonials and case studies from reputable firms that have reported tangible enhancements in production efficiency and material quality, directly attributable to the strategic implementation of carbon raisers. Partnering with a supplier who offers proven testing results and a track record of quality assurance can ensure consistent performance in meeting stringent industry standards. Moreover, innovative applications continue to emerge, from enhancing 3D printed metal components to advancing eco-friendly production methods. Such innovations demonstrate the dynamic applicability of carbon raisers, cementing their status as a cornerstone material in metallurgical advancements and a catalyst for sustainable industrial practices. As industries continue to innovate and demand higher performance materials, the role of carbon raisers is set to expand, ensuring they remain an essential resource for achieving excellence in metal production.

Trustworthiness is further reinforced by testimonials and case studies from reputable firms that have reported tangible enhancements in production efficiency and material quality, directly attributable to the strategic implementation of carbon raisers. Partnering with a supplier who offers proven testing results and a track record of quality assurance can ensure consistent performance in meeting stringent industry standards. Moreover, innovative applications continue to emerge, from enhancing 3D printed metal components to advancing eco-friendly production methods. Such innovations demonstrate the dynamic applicability of carbon raisers, cementing their status as a cornerstone material in metallurgical advancements and a catalyst for sustainable industrial practices. As industries continue to innovate and demand higher performance materials, the role of carbon raisers is set to expand, ensuring they remain an essential resource for achieving excellence in metal production.

Next:

Latest news

-

Fe-C Composite Pellets for BOF: Enhance Steelmaking Efficiency

NewsAug.07,2025

-

Eco-Friendly Granule Covering Agent | Dust & Caking Control

NewsAug.06,2025

-

Fe-C Composite Pellets for BOF: High-Efficiency & Cost-Saving

NewsAug.05,2025

-

Premium Tundish Covering Agents Exporters | High Purity

NewsAug.04,2025

-

Fe-C Composite Pellets for BOF | Efficient & Economical

NewsAug.03,2025

-

Top Tundish Covering Agent Exporters | Premium Quality Solutions

NewsAug.02,2025